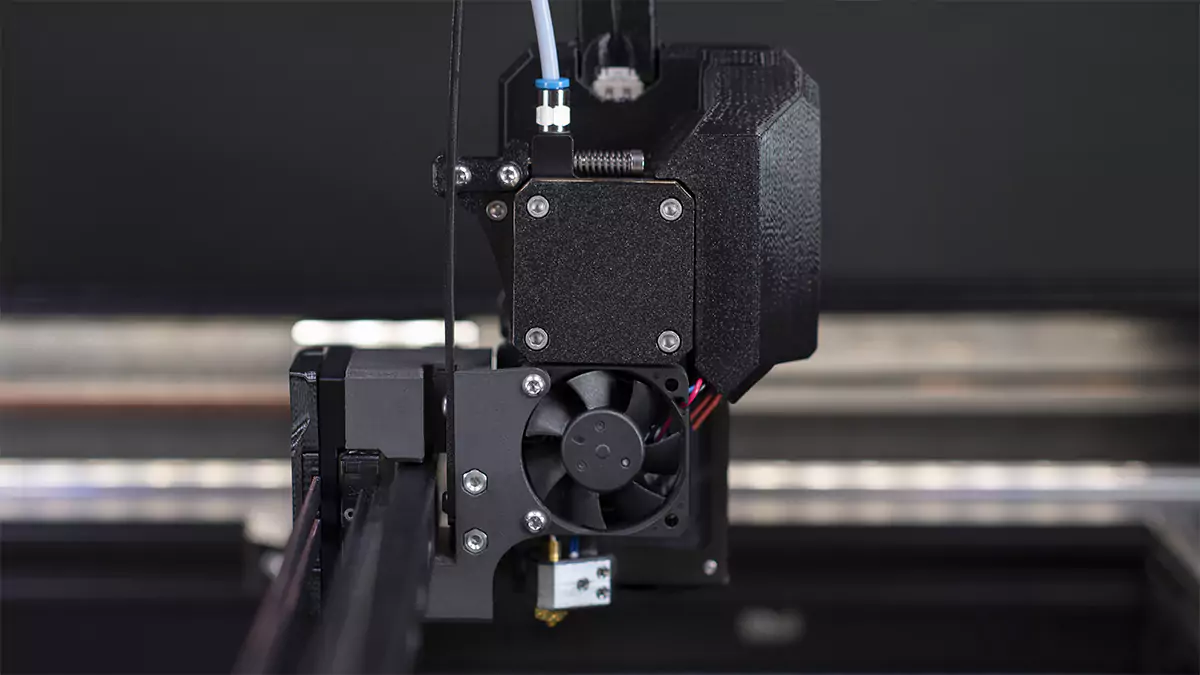

The Prusa XL includes a completely redesigned extruder with a planetary gearbox, hot-swappable nozzles, and a Load Cell-based system for fully automatic first layer calibration. There is no manual calibration and no Live Z adjustments. Every time you start a print, the XL produces a perfect first layer across the entire surface.

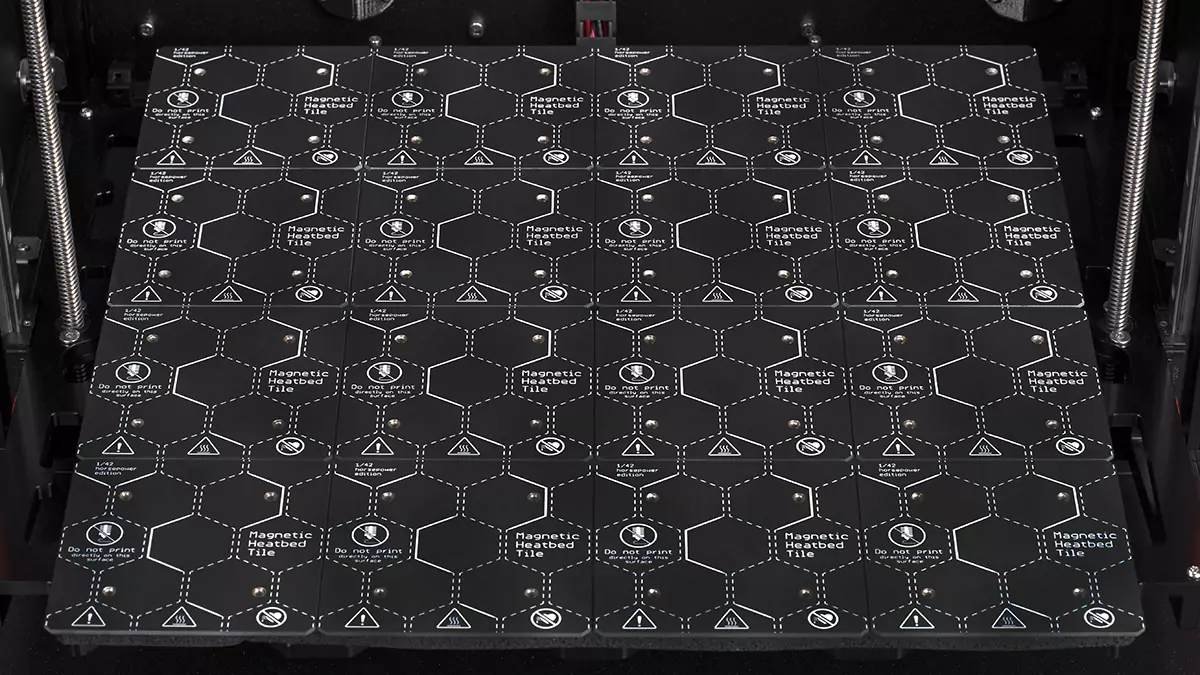

The XL's modular bed design improves print quality even further; rather than using a single large heatbed that is prone to warping, the Prusa XL 3D Printer employs an array of smaller, individually-controlled segments. When printing smaller objects, only the necessary portion of the heatbed is activated, making the XL energy-efficient. The XL, like other Original Prusa 3D Printers, employs proven double-sided spring steel sheets with a variety of surfaces, allowing for easy maintenance and print removal.

The Nextruder is a brand new extruder for Original Prusa 3D Printers that was designed from the ground up. The Nextruder is significantly lighter and packed with cutting-edge technologies, such as a minimal-backlash gearbox and no-slip drive gear, and is designed to deliver top-tier performance and stunning 3D Prints.

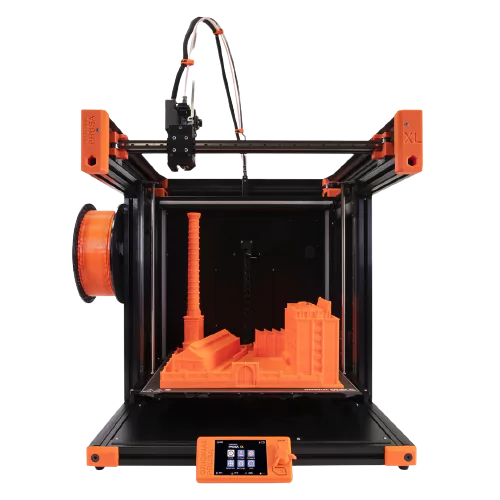

The XL is built around a strong aluminium extrusion frame, which gives it stability and rigidity. The XL delivers great-looking 3D Prints up to 36 x 36 x 36 cm thanks to high-quality stepper motors, linear rails, and an energy-efficient heatbed with 16 individually controlled segments.

Finishing large prints can easily take several days. You shouldn't be concerned about power outages, though. Hardware-based power-loss recovery is a feature of the XL. The XL stores the last known extruder location in case of a power outage, allowing the machine to resume exactly where it left off when the power is restored.

The Load Cell feature of the Nextruder allows for a fully automated first layer calibration WITHOUT ANY USER INTERVENTION. No tuning, no adjustments. The XL delivers a flawless first layer every time by precisely measuring the distance between the nozzle and the sheet prior to each print.

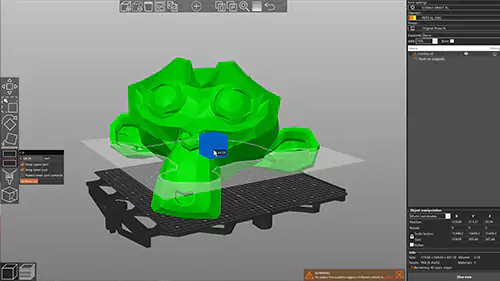

For all of our 3D Printers and a variety of filaments, our in-house created and thoroughly tested multiplatform slicer comes with profiles. Your 3D models will be converted into print files quickly thanks to the built-in tools, which include cutting, automated object distribution, advanced support generation, and many others.

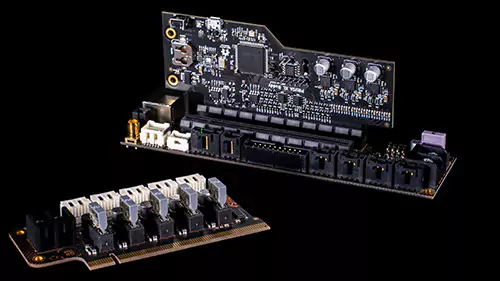

A new 32-bit motherboard that has an expansion port, which enables a simple upgrade to up to five tool heads, powers the XL. The XL is simple to set up and use and includes well-liked improvements like one-click printing and G-code preview.

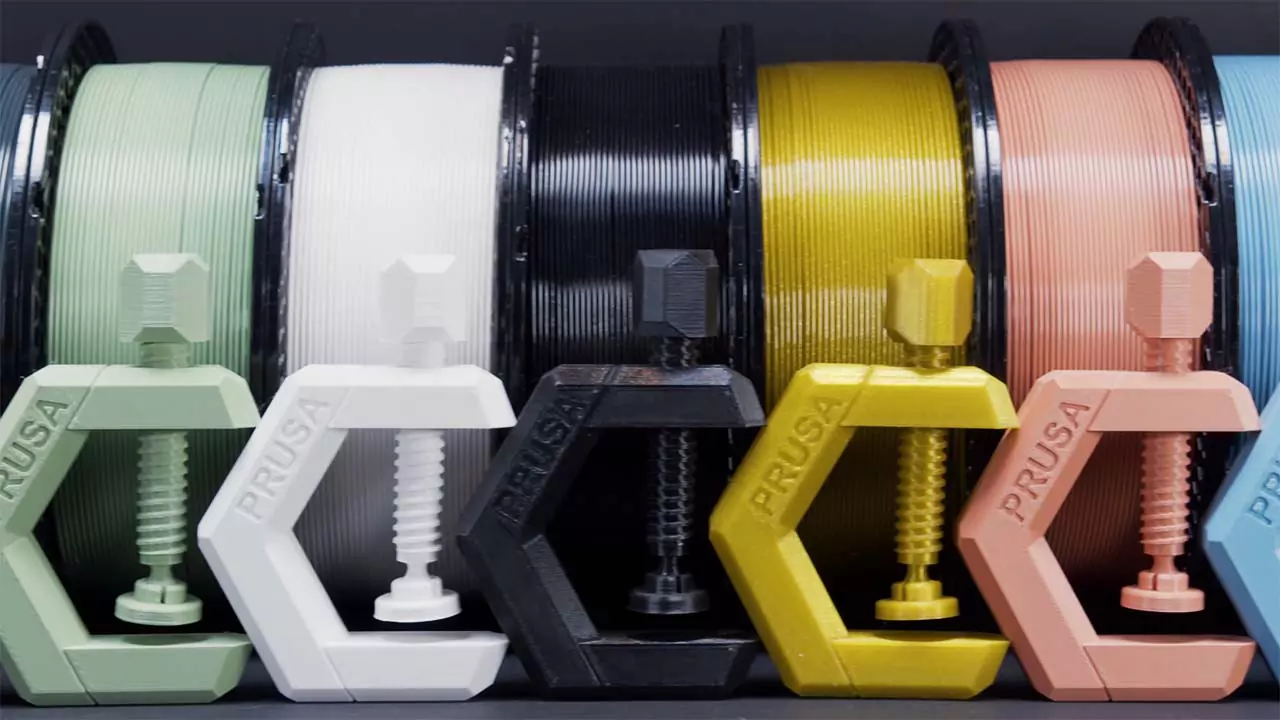

The XL is completely compatible with many different kinds of materials. The XL can print anything, whether it's something you want to make for fun out of PLA and flexible materials or you need to make durable prototypes out of PETG, ASA, Polycarbonate, and Polypropylene.

Up to 5 distinct print heads, each driven by a separate electronics board, can be added to the XL. Millions of trouble-free tool swaps are guaranteed by the internally developed toolchanger's dependable wear-resistant system and fully automatic tool alignment calibration. This facilitates quick and simple printing with soluble supports and multiple colours.

Technology

Fused deposition modeling (FDM)

Connectivity

Ethernet, Wi-Fi

Nozzle size

0.6 mm

Print recovery

Yes

Filament sensor

Yes

Max. hot end temperature

300 °C

Assembly

Semi-assembled

Extruder

Planetary 1:10 gearbox with no-slip drive gear, Load Cell sensor

Tool Changer

with up to 5 tool heads (optional upgrade via built-in expansion port)

Bed

Segmented heatbed with 16 individually controlled segments

Print surface

Removable magnetic steel sheets with different surface finishes

Electronics

32-bit custom-made board with an expansion slot, single-cable communication with tool heads, network features, one-click printing

Power panic

Hardware-based, single G-Code line accuracy

Ethernet connection

Built-in

Mesh Bed Levelling

Load Cell-based fully automatic first layer calibration with no Live Z adjustment

Printer design

Core XY

Build volume

360×360×360 mm

Printer dimensions

800×800×900* mm including side spoolholders and top enclosure cover (separate future add-on)

Filament diameter

1.75mm, wide range of thermoplastics supported (including, but not limited to PLA, PETG, ASA, ABS…)