3Ding

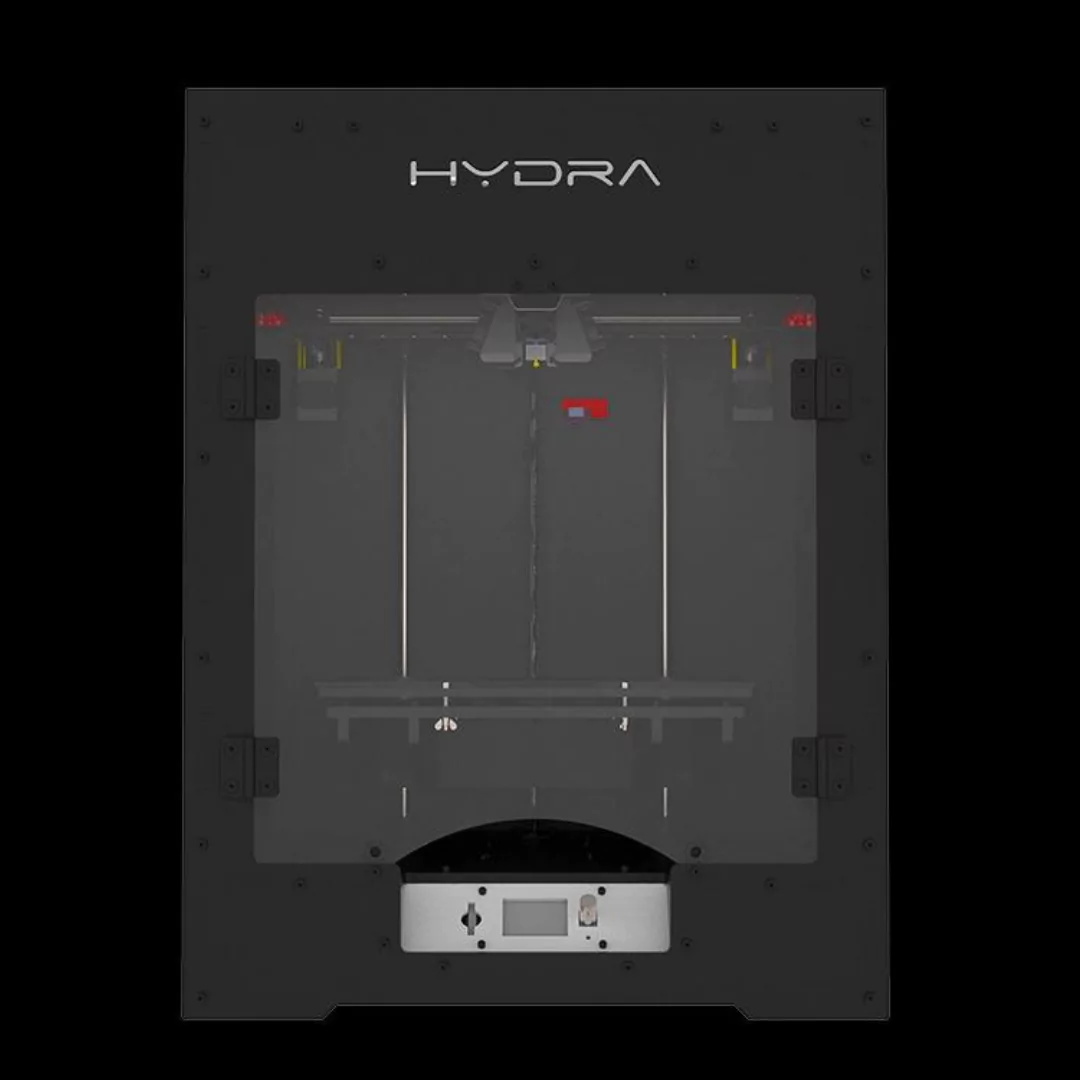

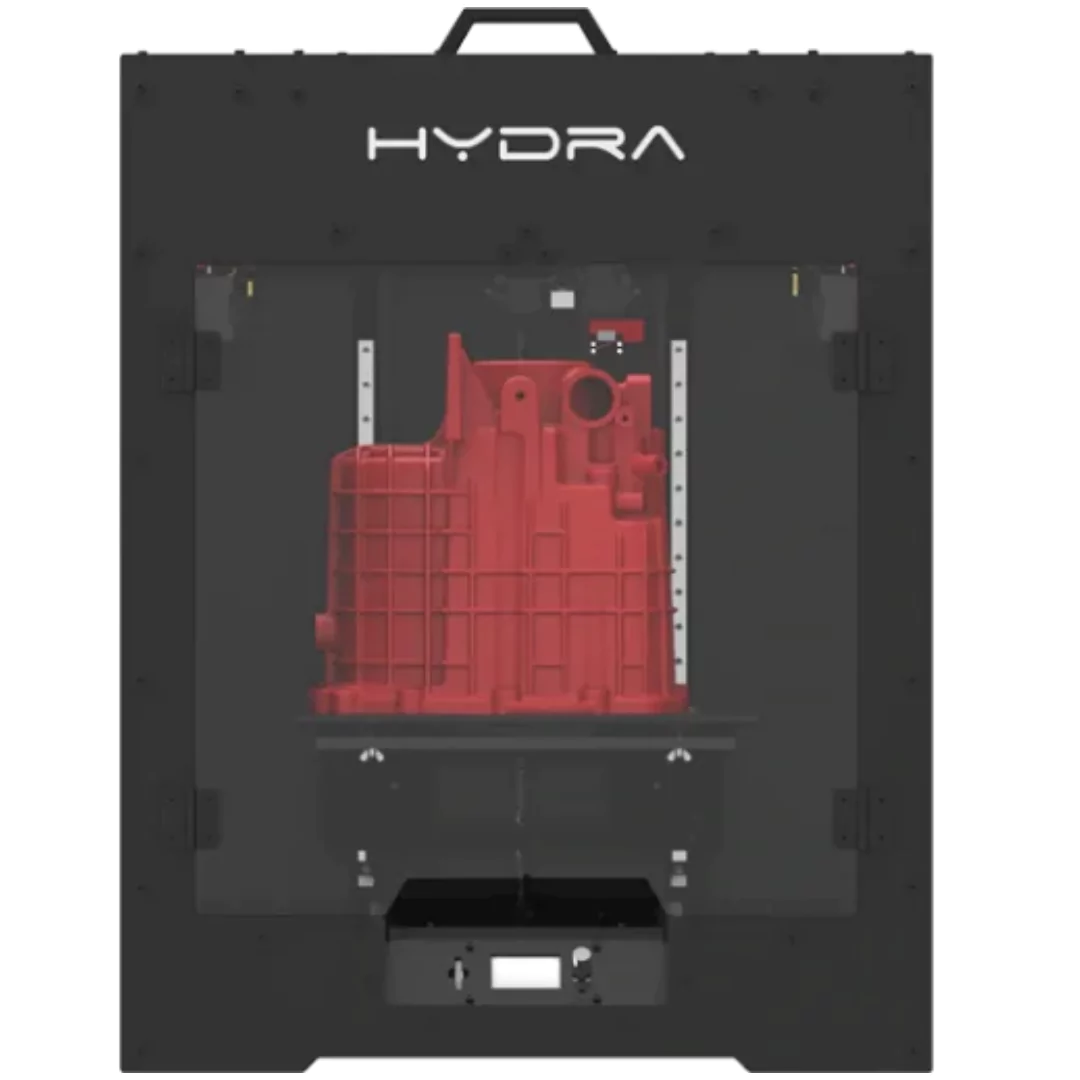

Hydra 3D Printer

Incl. of all taxes • Free shipping

Hydra 3D Printer - Hydra 200

₹99,999

₹99,999

Meet The Hydra

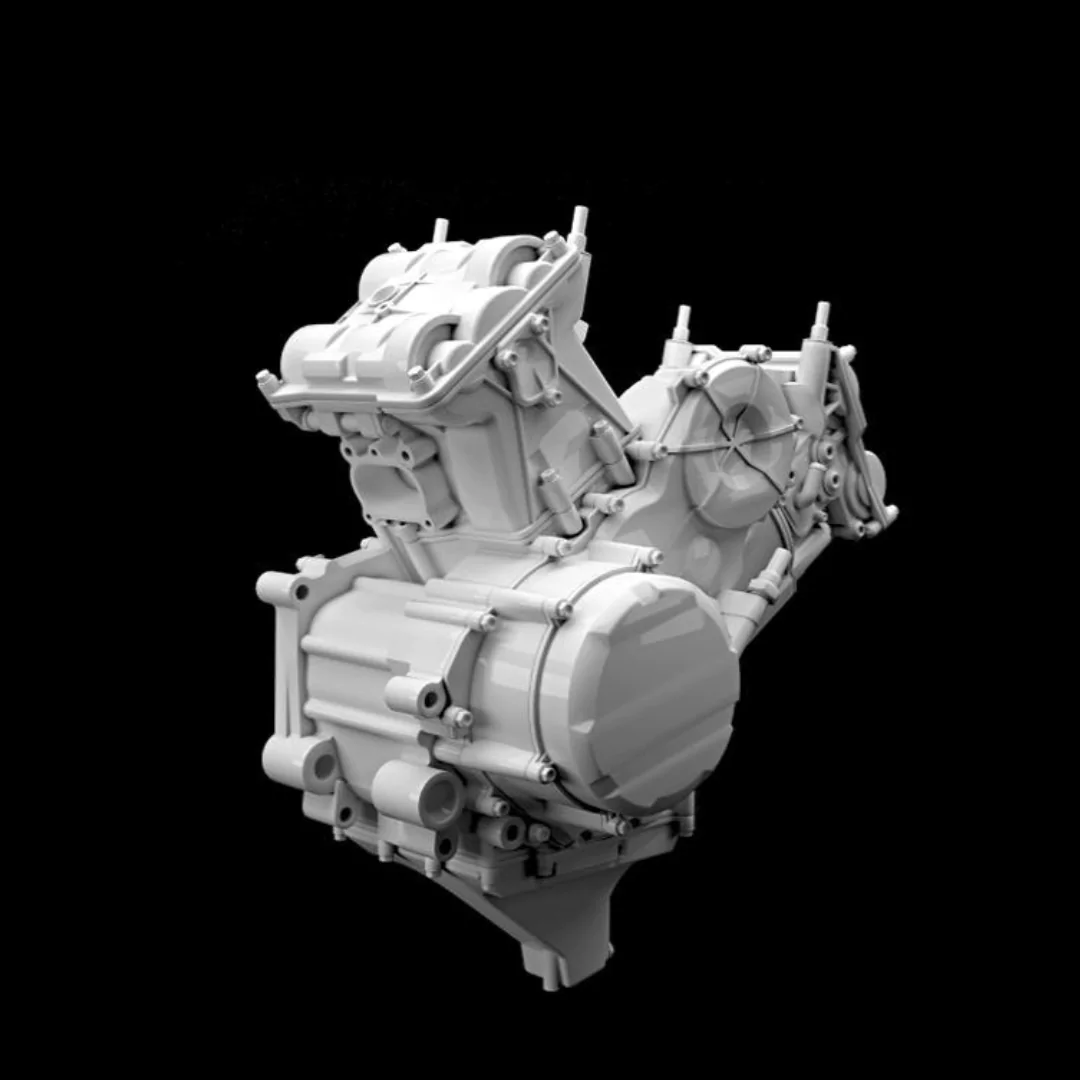

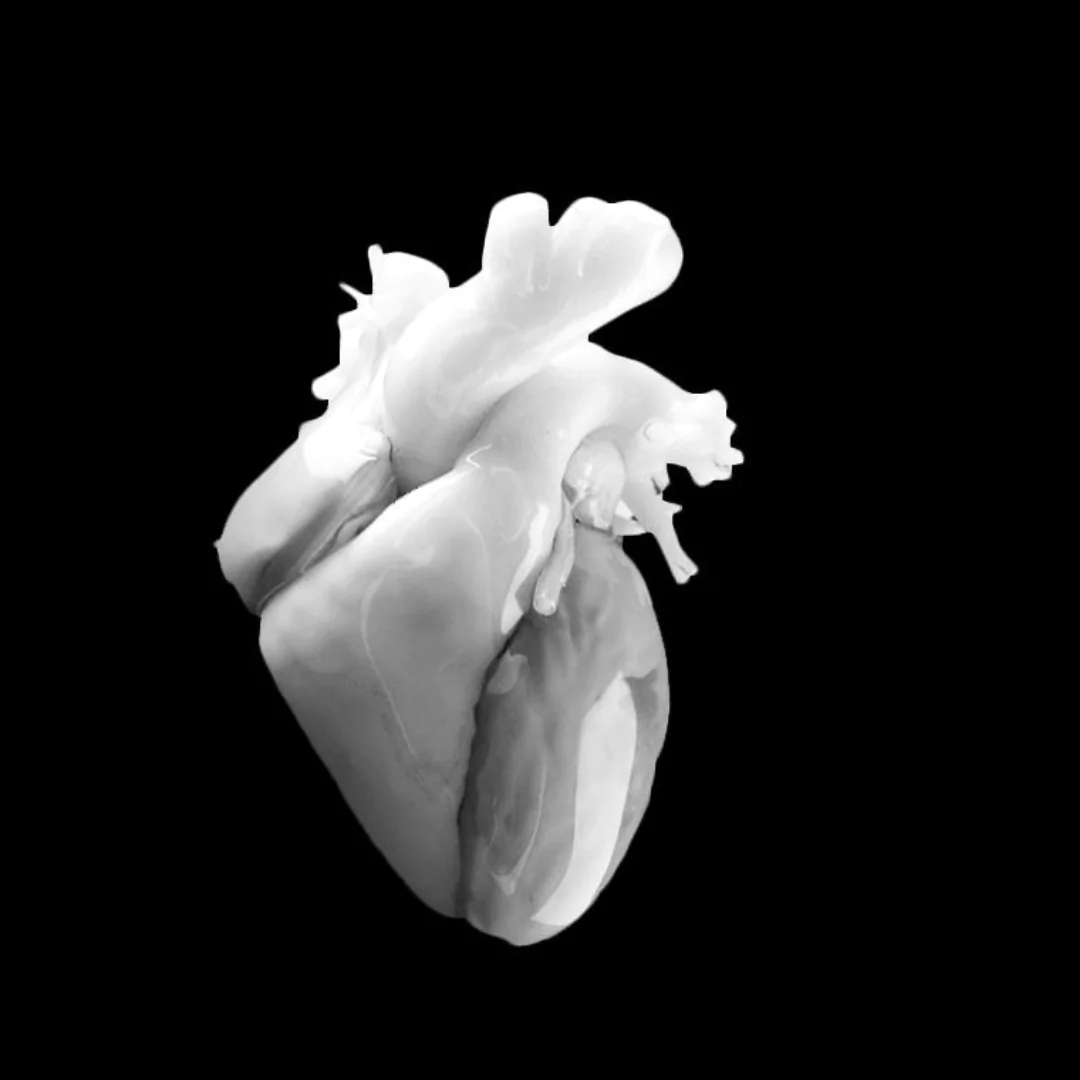

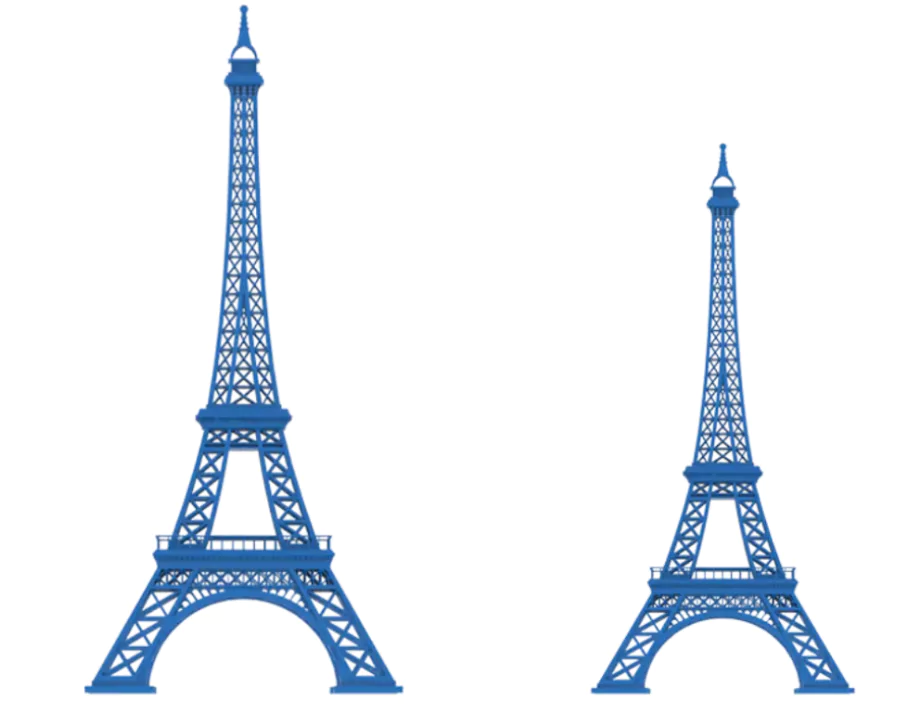

An Industrial 3D Printer for Rapid Prototyping

From functional mechanical parts to beautifully designed architecture models, the Hydra delivers unparalleled print quality with industrial-grade precision. Run through hundreds of designs, test multiple ideas, and perfect your product in hours instead of weeks.

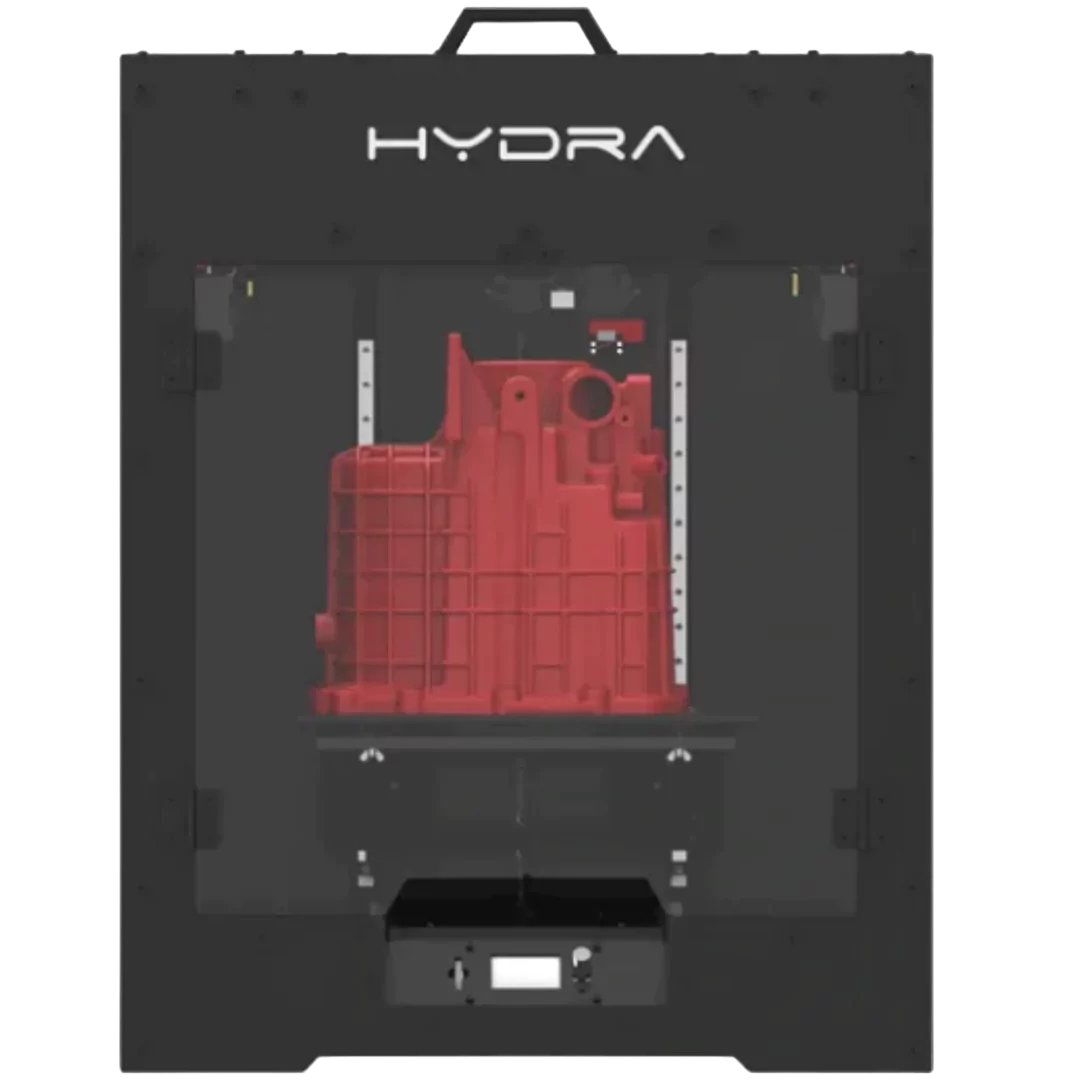

Available in 3 Sizes

Hydra New 200

200 × 200 × 200 mm³

Hydra 250

250 × 250 × 250 mm³

Hydra 300

300 × 300 × 300 mm³

Where Performance Meets Practical Applications

Features of Hydra 3D Printer

Unparalleled Print Quality

With Linear Guideways powering the gantry, the Hydra is up to 2x precise compared to any other 3D Printer using linear rods. Experience industrial-grade precision in every layer.

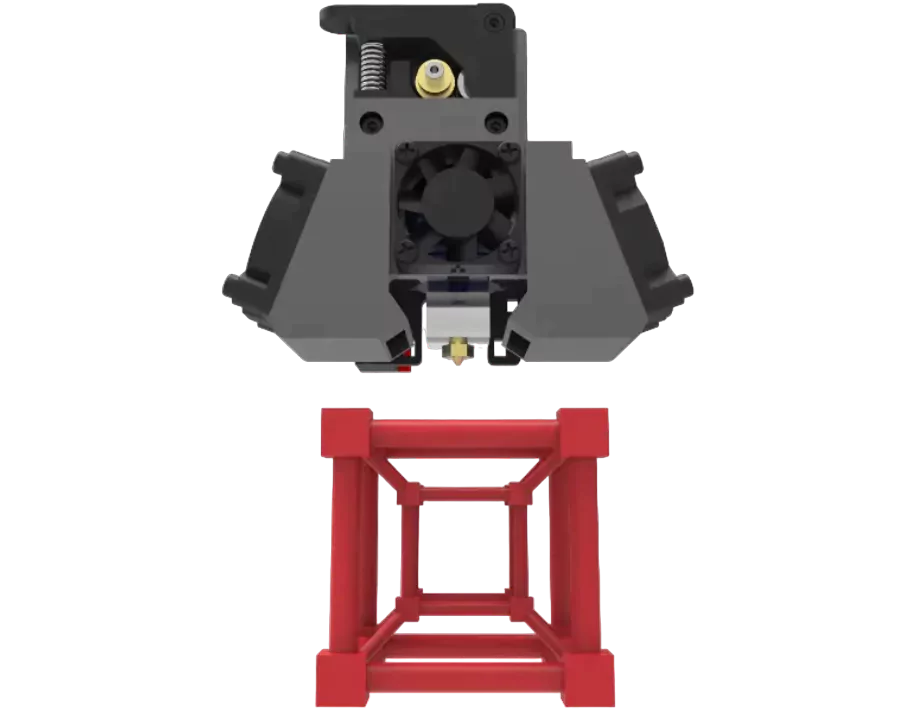

Direct Drive Mechanism

Enables high precision 3D Printing with minimal to no vibrations at incredible accuracies. The direct drive system ensures consistent filament feeding and superior print quality, especially with flexible materials.

E3D v6 Hotend

Upgraded Nozzle with high temperature capabilities opening up possibilities for advanced Materials, including ABS, Nylon, Carbon Fiber etc. Print at temperatures up to 300°C with confidence.

Heated Bed - Upto 120°C

Enables high precision 3D Printing with minimal warping. The heated bed ensures perfect first layer adhesion across all materials, from PLA to high-temperature engineering plastics.

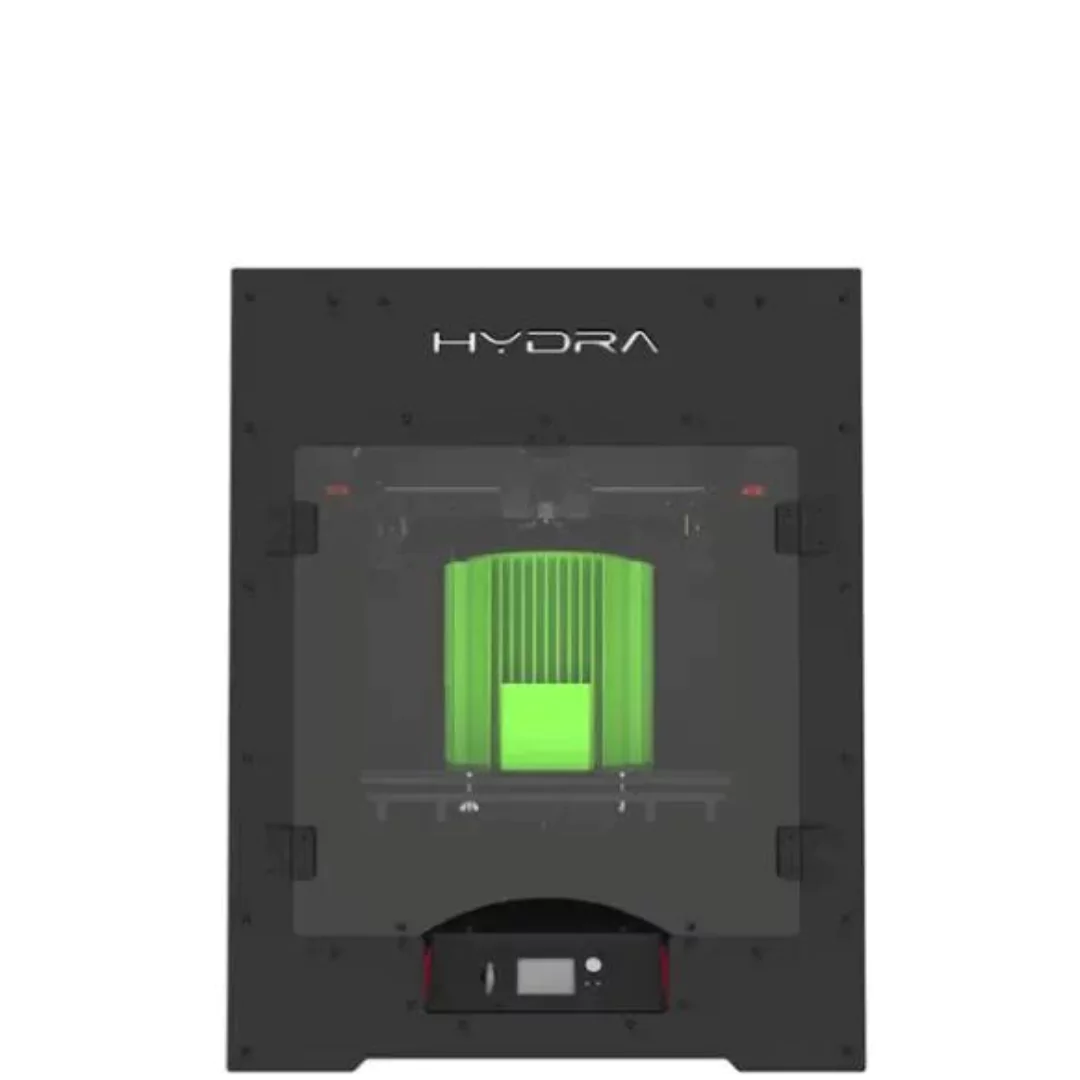

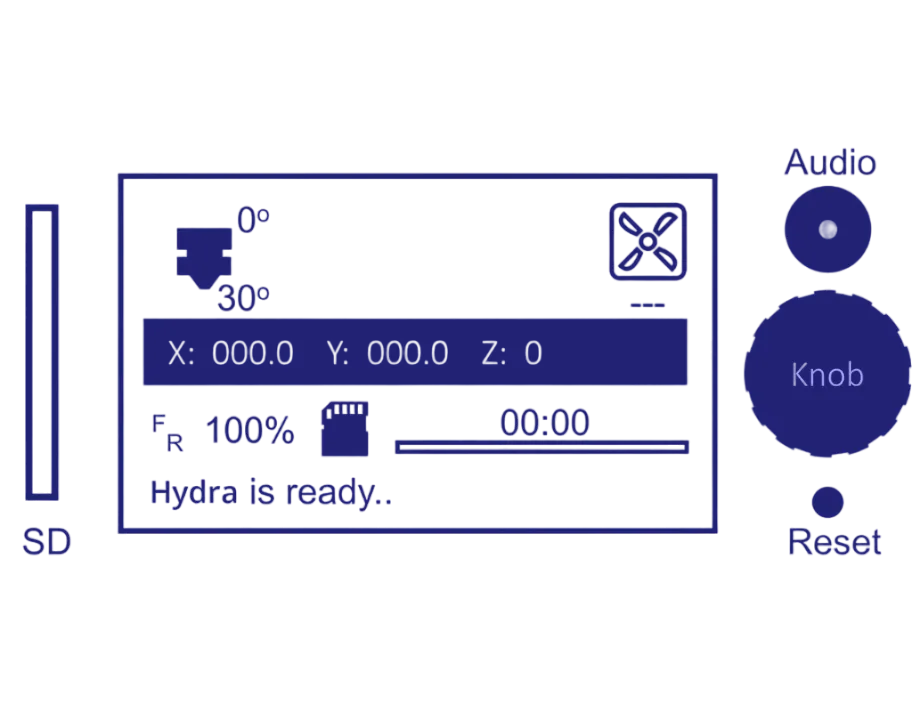

Active Triple Cooling System

State of the Art & Proprietary. The Hydra's extruder system sports 3 cooling fans. The hotend fan prevents heat from seeping up & preventing clogs. The two ducted fans provide rapid cooling to the part, thus enabling the Hydra to handle extreme bridging with minimal to no supports. This also enables the Hydra to 3D Print at high speeds with ease.

MagFlex Build Surface

Don't Fight it - Just Flex it! The Hydra features MagFlex v2.0 - The all New Build Surface adheres better & prevents warping. The Flexible system helps remove parts fast & easy. It's Magnetic and more flexible for ultimate convenience.

Material Compatibility

Standard Materials

- PLA

- ABS

- PET-G

- HIPS

Engineering Materials

- Nylon

- Carbon Fiber

- Flexible (TPE/TPU)

Composites

- Wood

- Silk

- Metal Composites

Metal Composites

- Aluminium

- Gold

- Brass

- Bronze

- Copper

* Future Proofed to handle any other Filament that melts under 300° C

Technical Specifications

Printing

Mechanical

Software & Electrical

What's in the Box?

- Hydra 3D Printer

- PLA Filament Spool - 1Kg

- Documents - Checklist, Warranty & Support Document

- Toolkit - Nipper, Tweezers, Allen Keys, SD Card & Card Reader, Bowden Tube, Power Cable, USB Cable, REDD MagFleX Build Sheet

- Software - Cura, Prusa (Optimized Profiles), Sample Print GCodes

Related & Compatible Products

This section will show related products, compatible accessories, and recommendations.

Related Product 1

Related Product 2

Related Product 3