3Ding

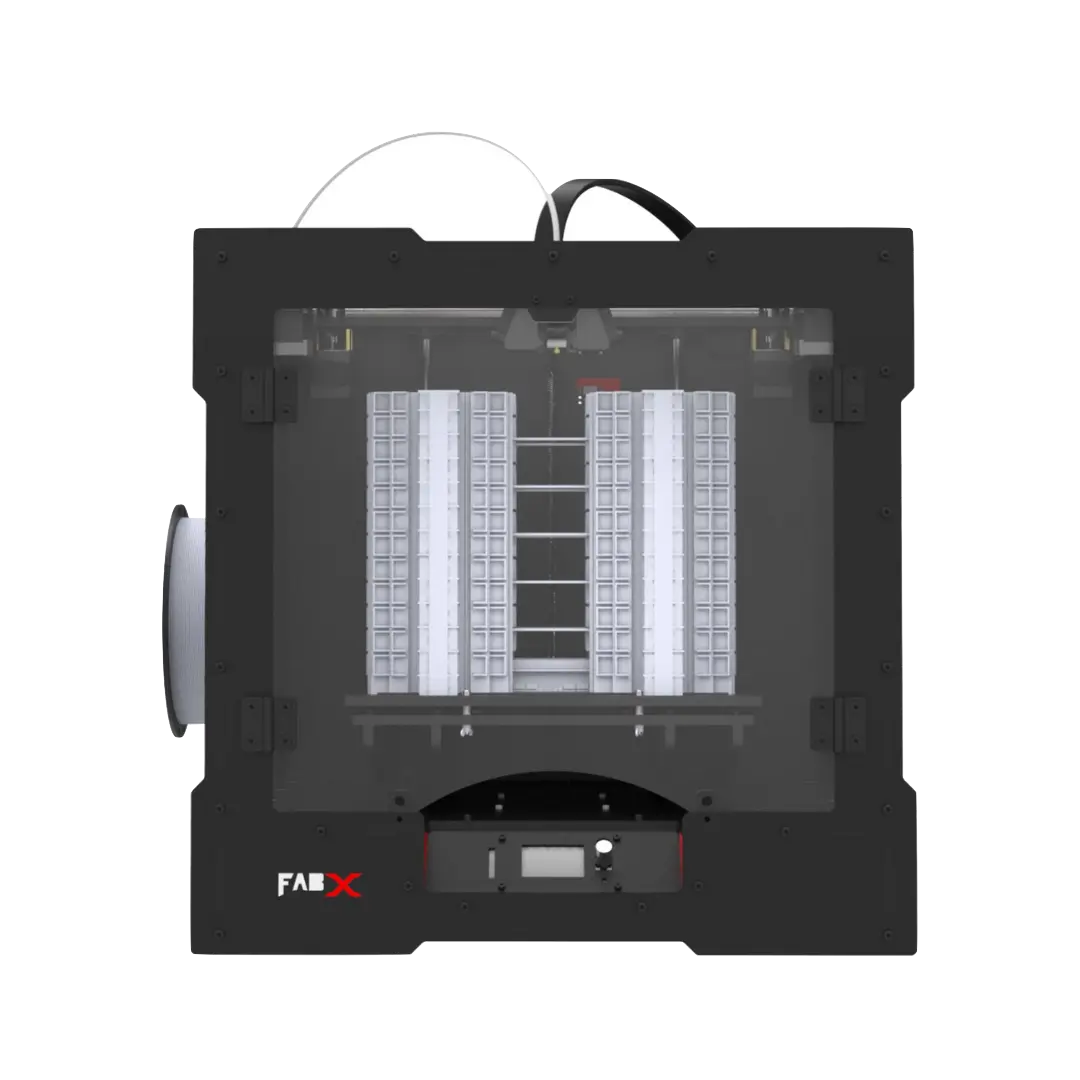

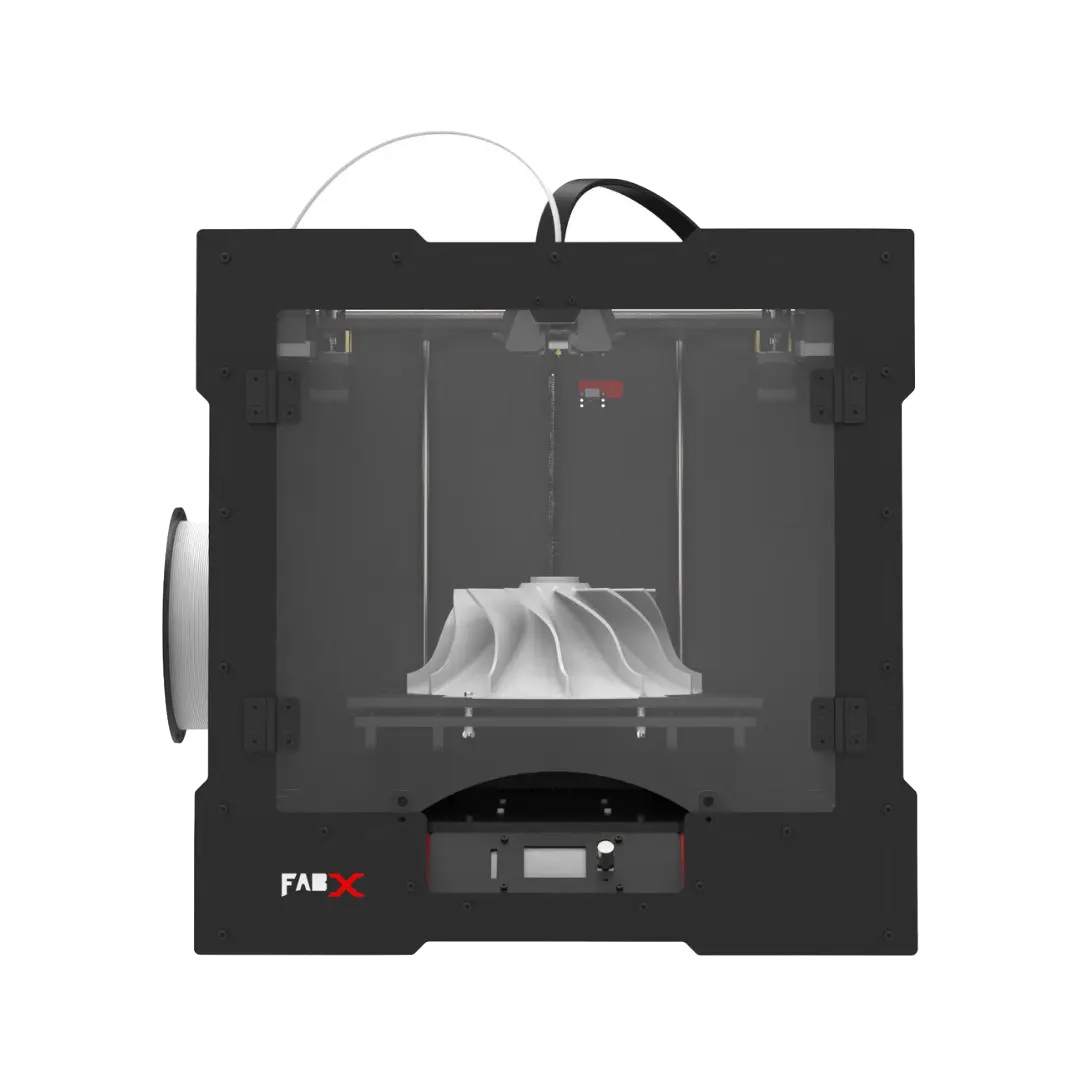

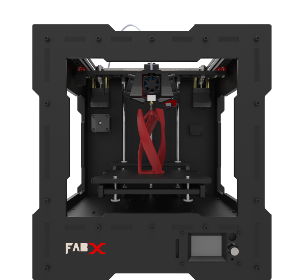

FabX 3D Printer

Incl. of all taxes • Free shipping

FabX 3D Printer

₹27,999

₹27,999

Find the FabX that's right for you

Choose from 4 powerful models designed for every need

FabX

₹27,999

FabX Plus

₹33,999

FabX Pro

₹69,999

FabX XL

₹1,19,999

Specialities of the FabX Series

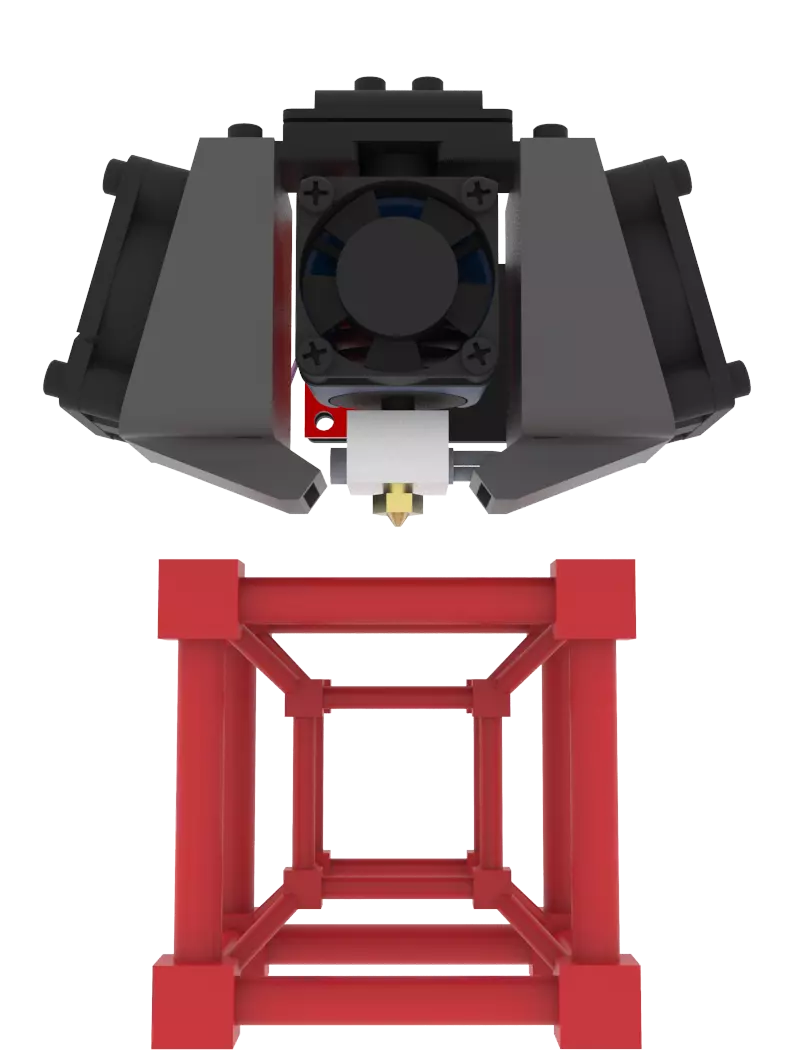

The FabX packs an E3D Hotend moving on premium Industry-Grade rails

Active Triple Cooling System

While the hotend fan prevents heat from seeping up & thus preventing clogs, the two other ducted fans provide rapid cooling, enabling the FabX to handle extreme bridging with minimal to no supports. This also makes the FabX print at high speeds with ease.

Snap & Silent

The New and Improved Snap Fit Assembly along with Hard Reinforced Fiber has helped us manufacture the most silent FabX ever. Snap Fit Mechanism also reduces vibrations and enables ultra high accuracy outputs.

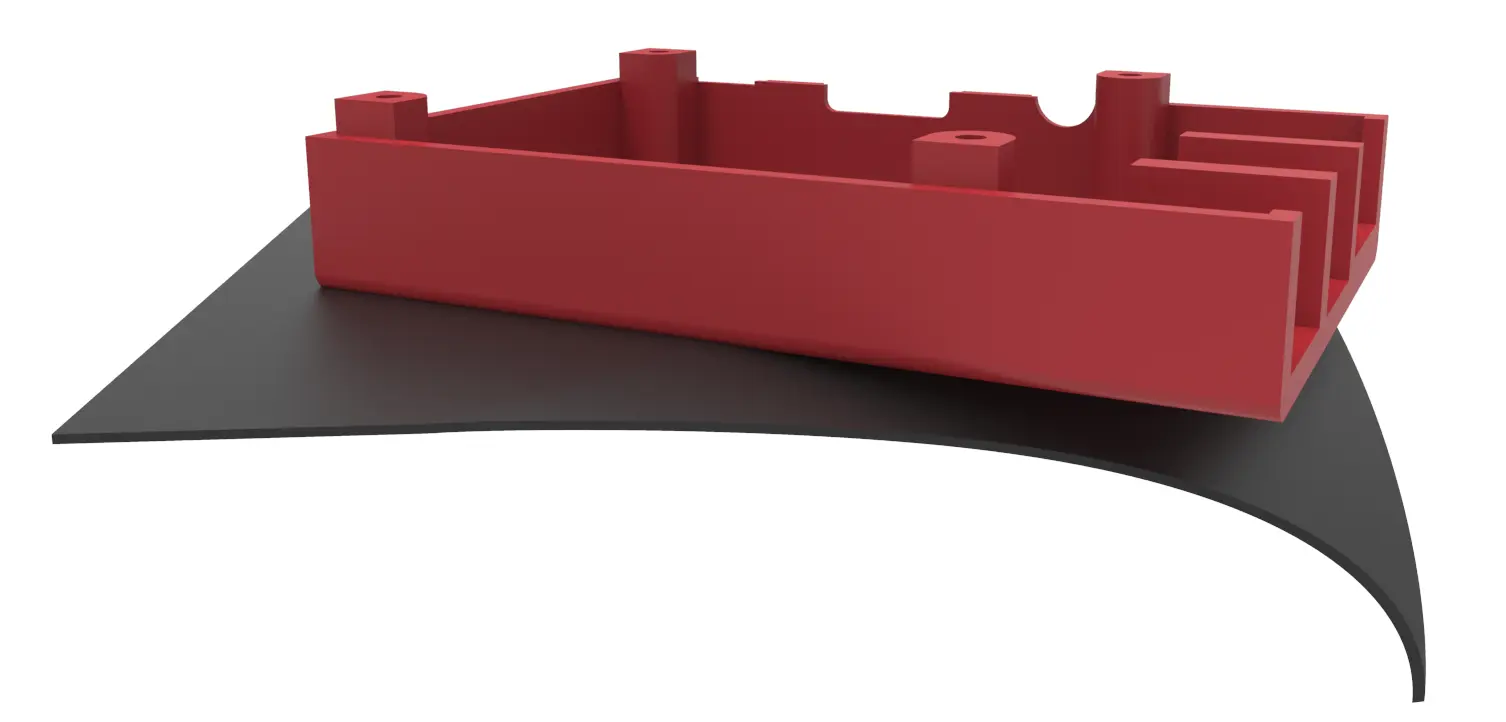

Don't Fight it - Just Flex it!

The brand new REDD MagFlex build platform is both magnetic and flexible, making it the most user-friendly build platform in a 3D Printer. Instead of fighting with the build plate to remove the object, all you have to do is flex the build sheet.

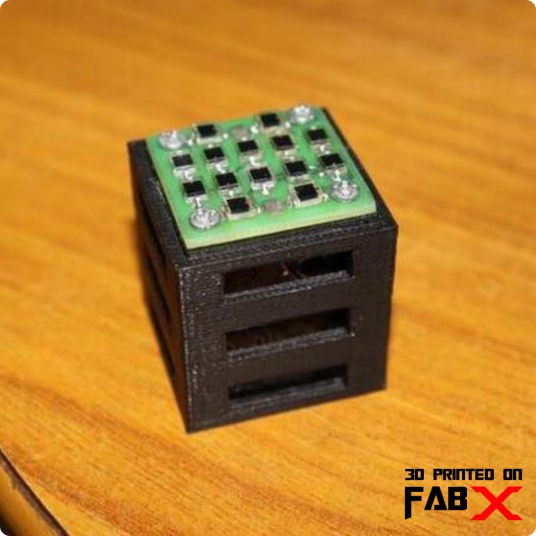

Powering Innovation Across Industries

From creative professionals to engineers, FabX delivers precision and reliability for diverse applications

Software Compatibility

Import from your favorite Design Platform

Tinkercad, Sketchup, Solidworks, Fusion360, Maya, Zbrush, Openscad & more. Design. Export as STL, OBJ, AMF. Slice. Print.

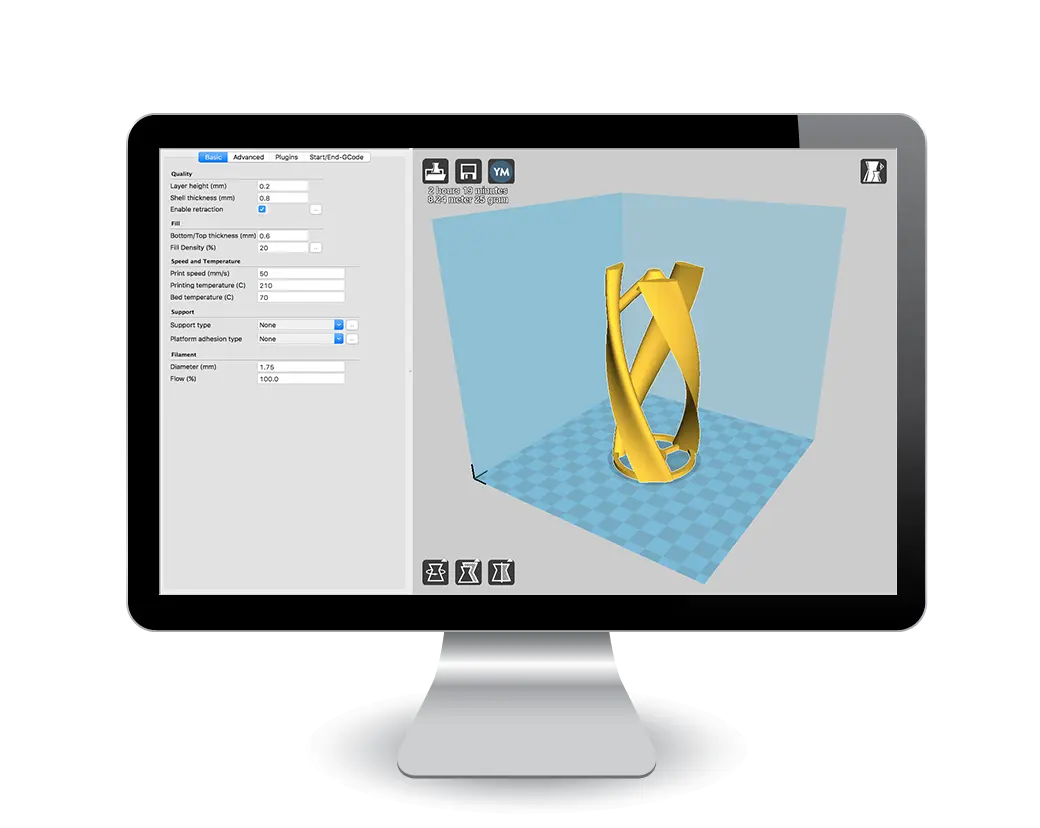

Slicing Software

The FabX runs Marlin, meaning it's compatible with a variety of Slicing Software: Cura, Simplify3D, Mattercontrol, Slic3r & more.

Recommended:

Beginners: Cura (Free)

Advanced: Simplify3D

Related & Compatible Products

This section will show related products, compatible accessories, and recommendations.

Related Product 1

Related Product 2

Related Product 3