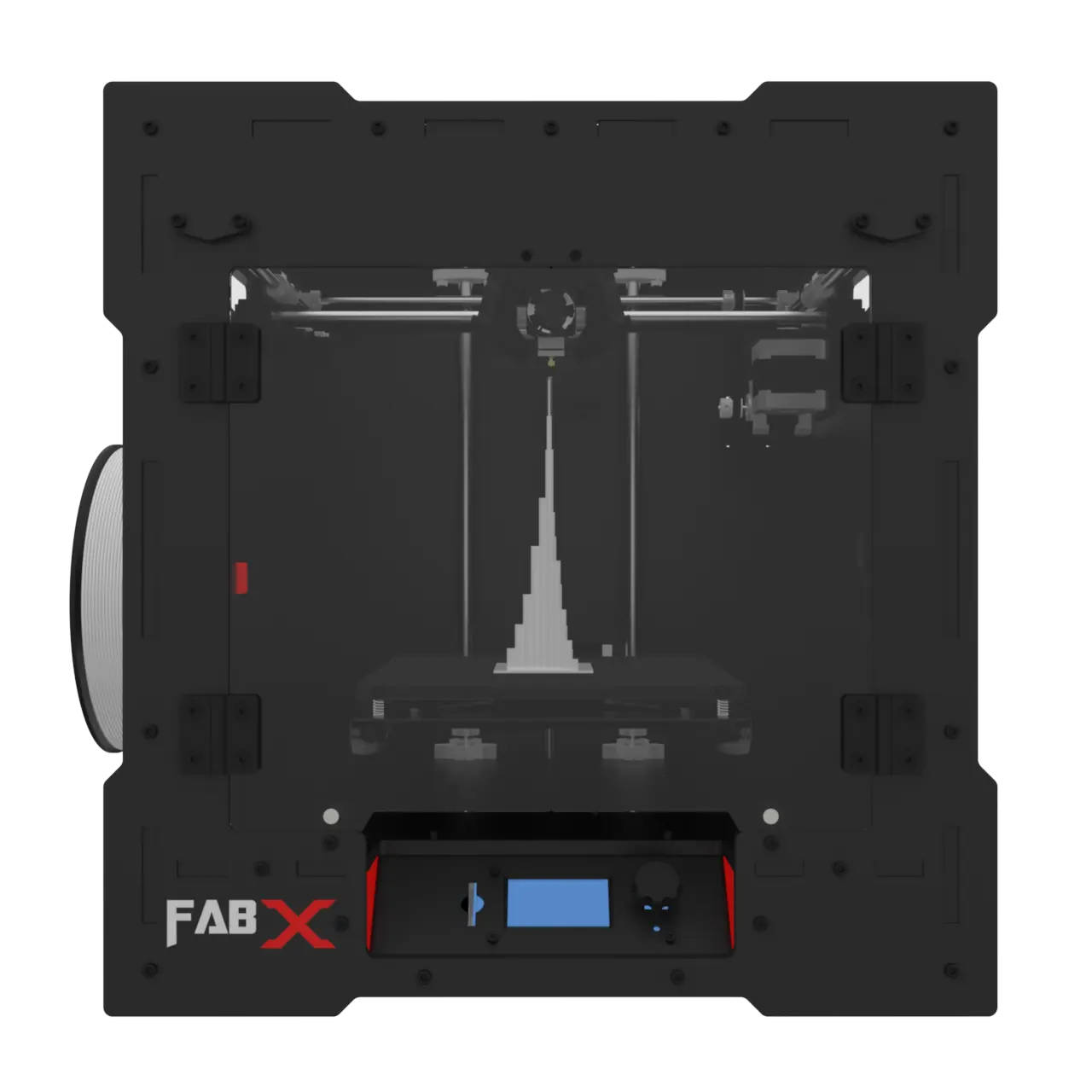

Not. So. Light.

Starting at ₹ 69,999/-

Starting at ₹ 69,999/-

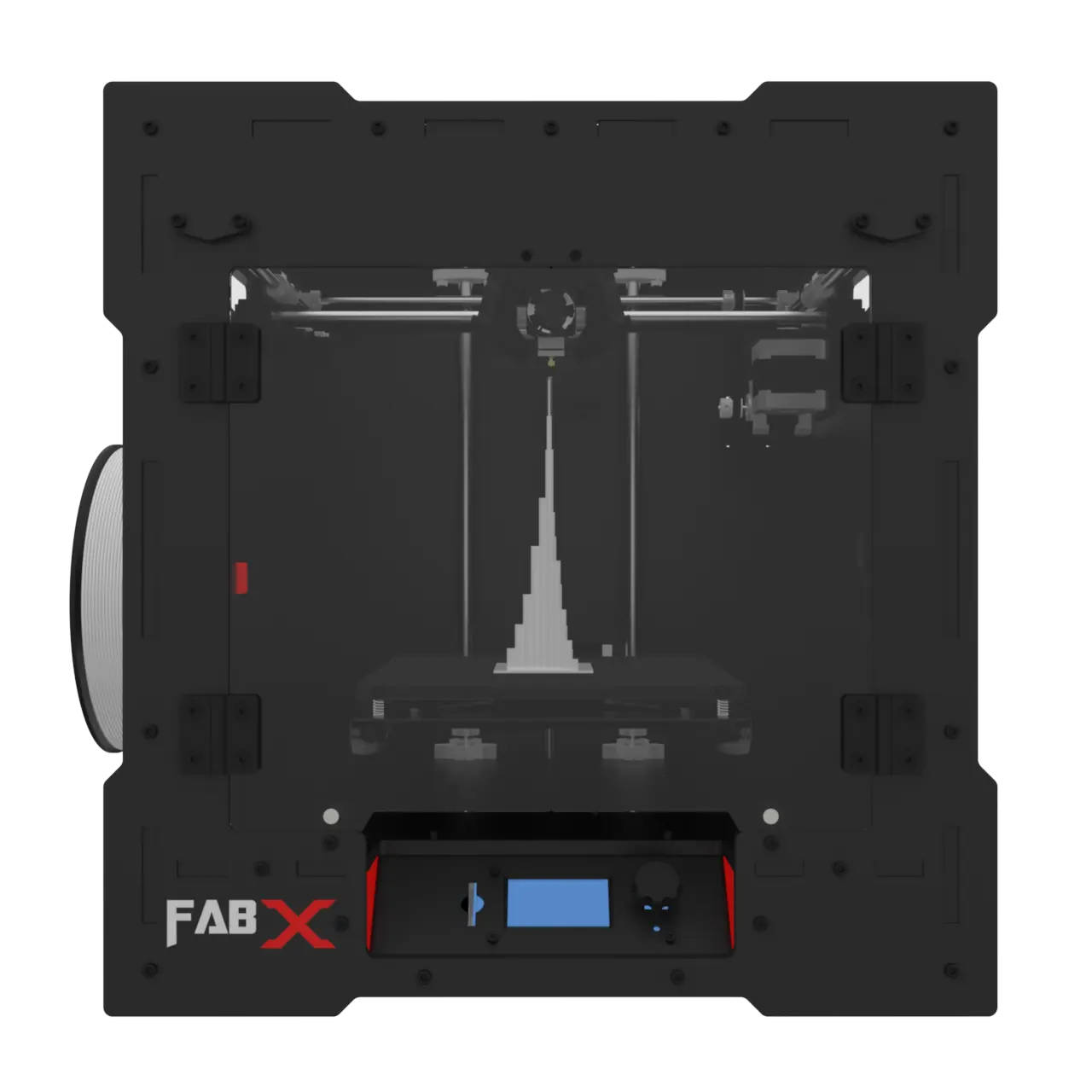

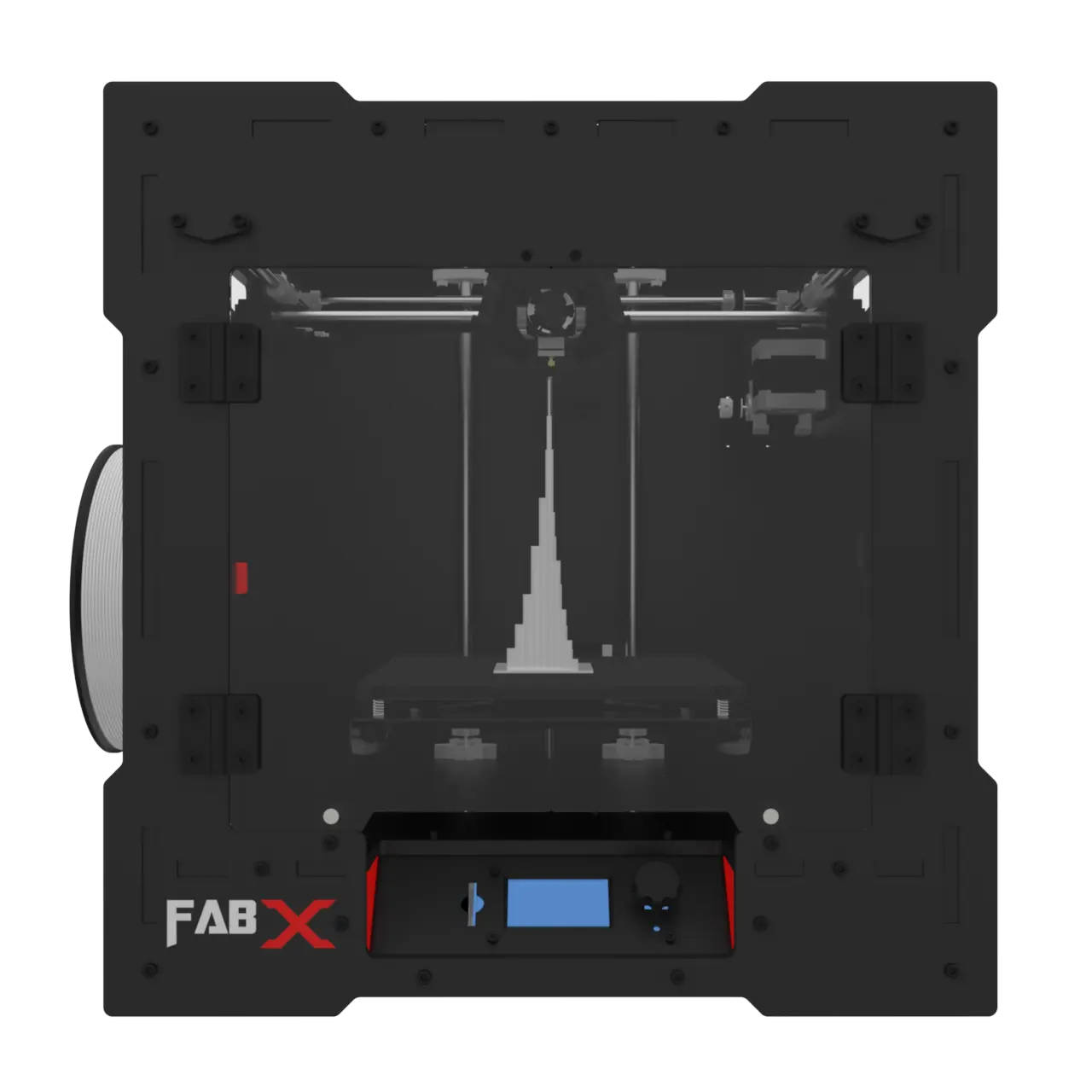

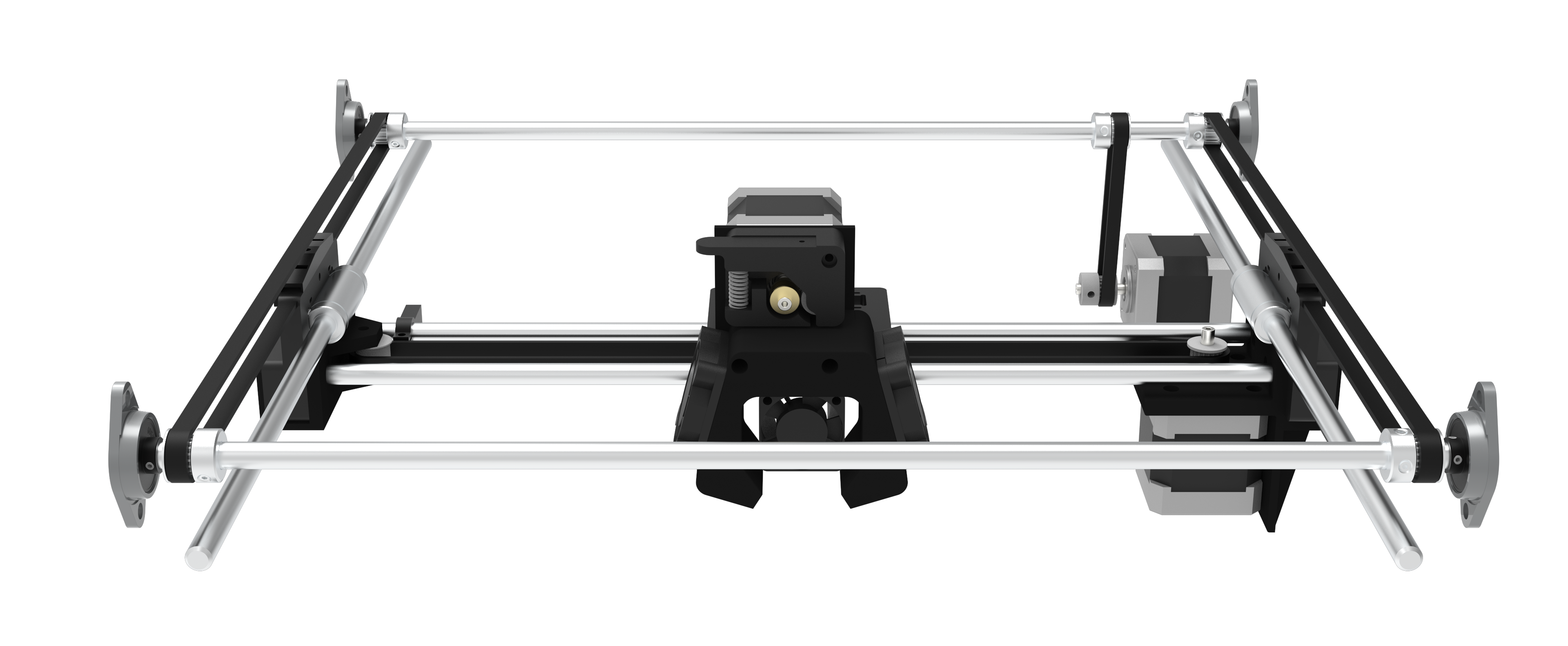

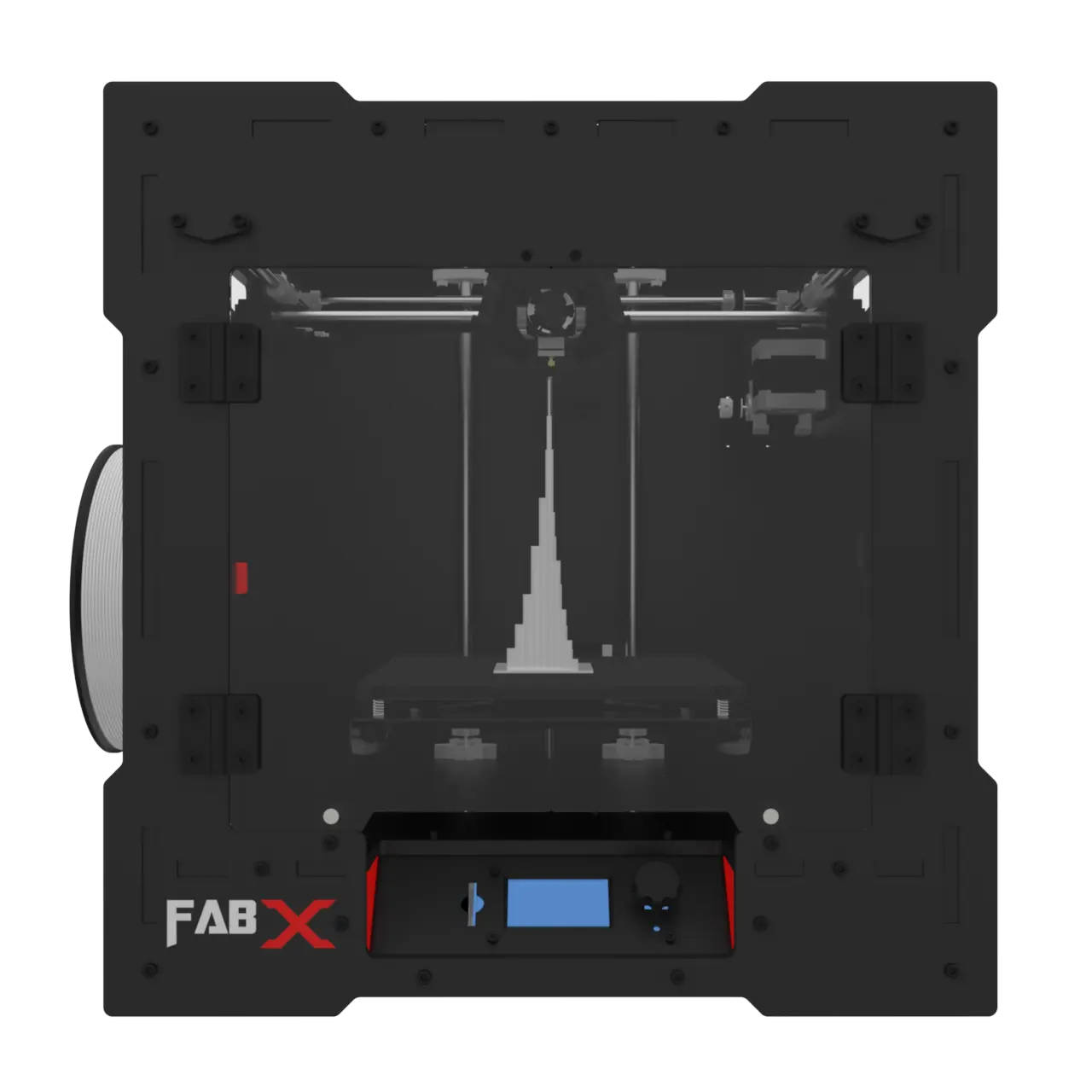

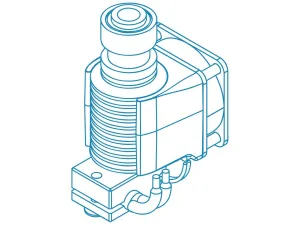

A “Lite” individually driven Cartesian Gantry that’s proven to deliver consistent quality in 3D Printers for over a decade.

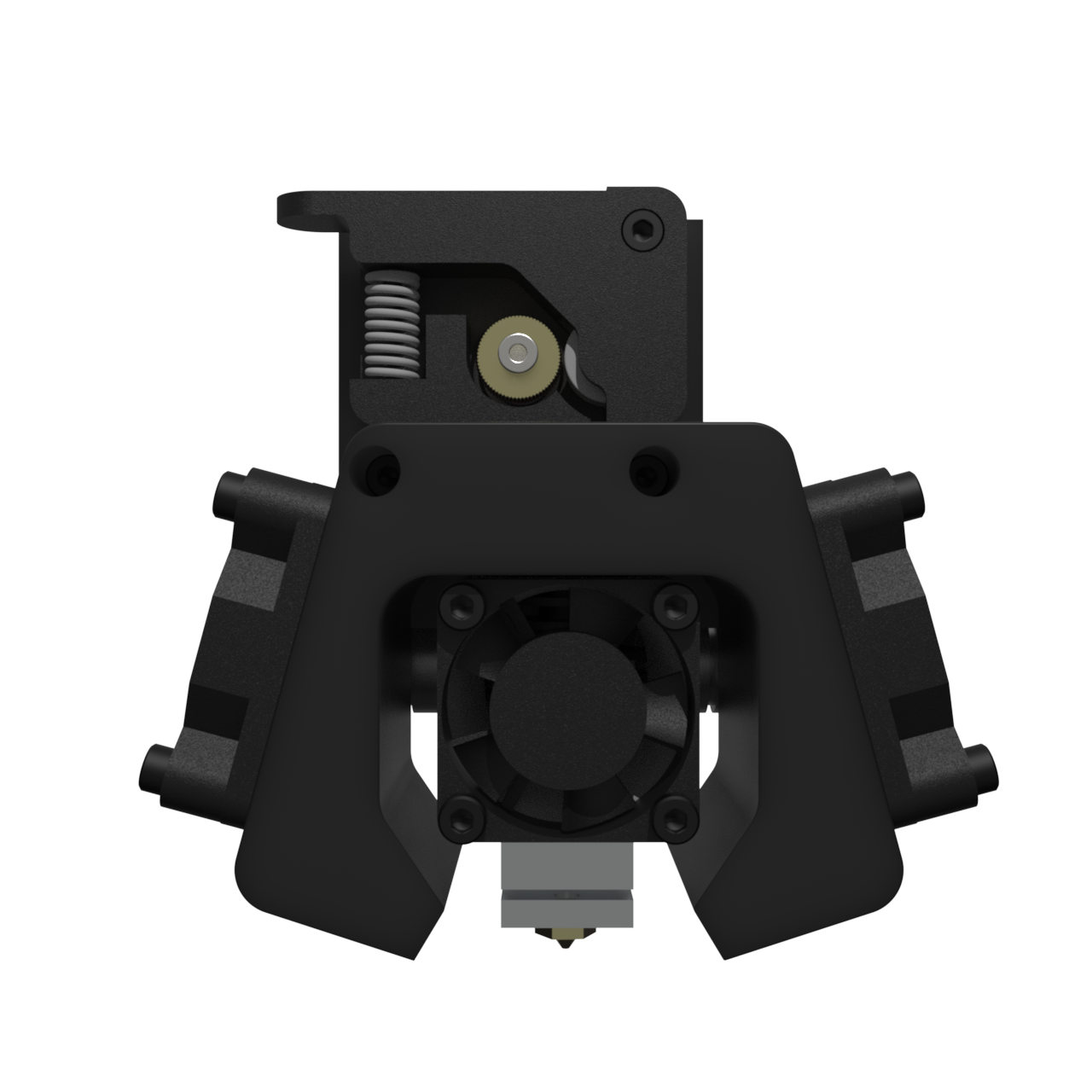

A Direct Drive Extruder System with the least travel path after the drive gear, which

translates to a precise control over filament flow, eliminating stringing or oozing

during

travel moves.

A World-Class E3D Hotend with internal Surface Roughness engineered for the smoothest

filament flow.

3D Printing is not just about heating & pushing out filament, but also cooling the

thermoplastic at the

right moment.

Sporting 3 Fans (1 to Make sure heat doesn't creep up & 2 to cooldown your Printed part),

FabX's

Signature Active-Triple-Cooling system gives the perfect cooling.

Defaulting a 0.4 mm nozzle means layer-heights upto less than 0.4 mm (let's say 0.35 mm).

Perfect for those super-quick draft-quality Prints during your ideation stages.

...but, for those super slanty slopes or a fine output requirement, push the limits of your

FabX & go down to 50

microns(0.05

mm)

per layer.

In the image is an actual 3D Printed moai statue in HIPS with 50 micron layers (Not a render).

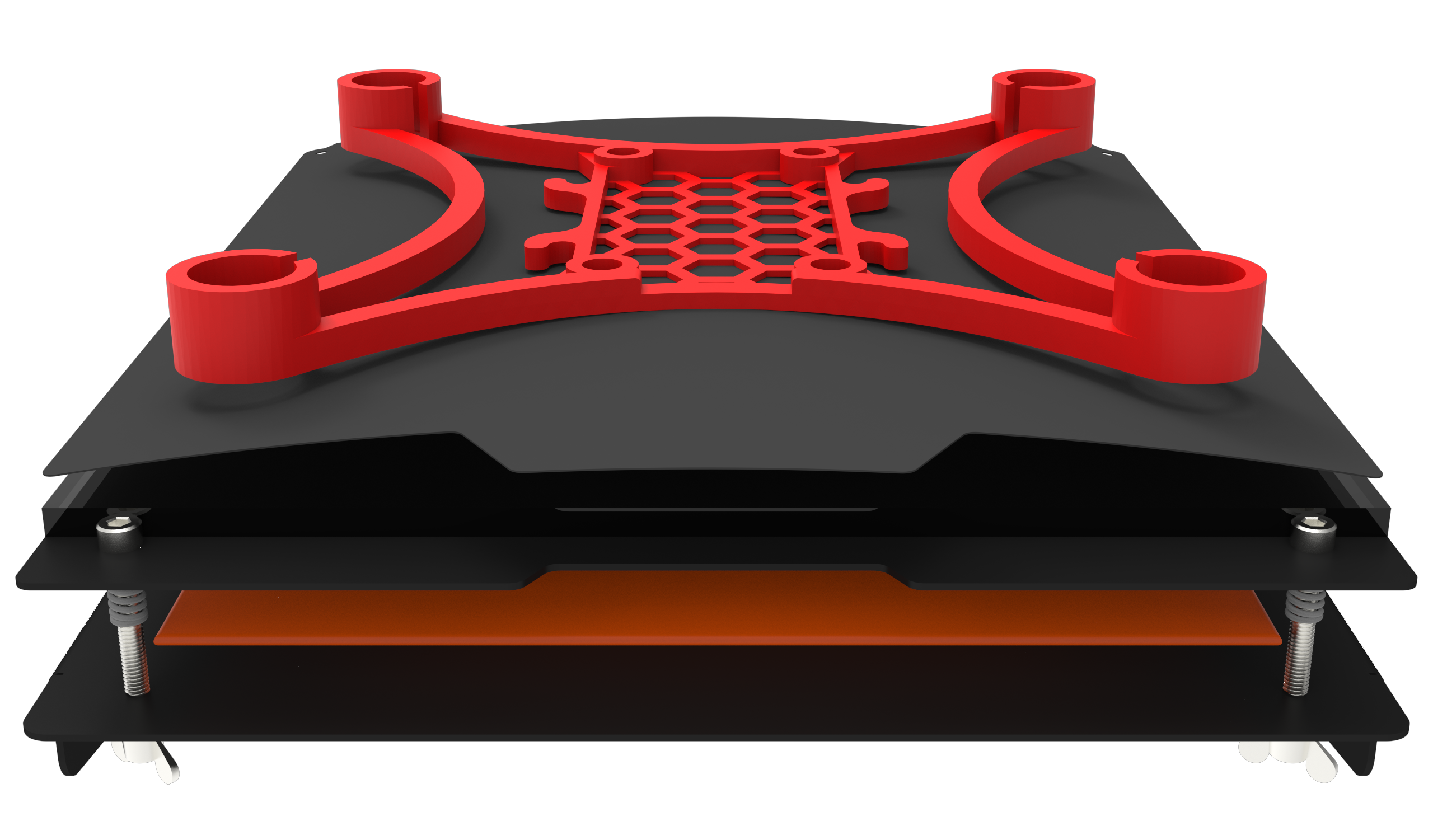

A non-contact optical limit switch homes your Z axis precisely,

in the range of 5 microns. 3 Points are all you need to level a plane &

the FabX Lite has them - Level it once with an assisted system when you

unbox your FabX (or transport it physically) & forget about levelling.

Get Perfect first layers every single Print!

Laser Cut Chassis out of Reinforced Lite Fiber, assembled by quick snapping; No bends, No

welds, Precision Engineered, making the axes perfectly right angled.

SD Card

USB

WiFi

Available as an Add-on

Runs Marlin 2.0

Think about Marlin like the Android of 3D Printers - The most popular Firmware running on a

3D Printer. With features like Linear Advance, Marlin 2.0 predicts filament pressure

build-up in the extruder & offsets it in advance, avoiding blobs.

Thermal Runaway Protection cuts off power supply to the heaters if any anomoly is detected.

Run your FabX overnights in peace.

Works with your Favourite Slicer.

Simplify3D, Cura, PrusaSlicer, SuperSlicer, Slic3r, MatterControl, any slicer that generates

Marlin comaptible gcode.

Unlike Most 3D Printers which remember the last known layer number, FabX 3D Printers remember & recover from the last known location of the extruder on the last known layer, reducing overlaps & hence a much precise recovery after a power loss.

The Most Popular Filament, ideal for quickly realizing your concepts

Easy to Use

Rapid Prototype your designs with ABS to check form & functionality.

Post Processing Friendly

A UV Resistant material, commonly used in Health-Care Appliances.

UV Resistant

Making rubbery Tyres for Your robots or cases for your Phones?

Flexible

For those unique applications where you want a 3D Printed part dissolved.

Dissolves in Water

Online Knowledge Base

Learning Modules

Call & Email Support

Extended Warranty @ 22.5% of MRP per Year.

Annual Maintenance Contract @ 12.5% of MRP Year.

Upto 3 Additional Years

With

historical lifespan of the FabX 3D Printers ranging 5+ years & increasing, repairability is

an important

aspect & has been built into FabX 3D Printers right since the FabX 3 in 2016.

If & When

you need

spares, you don't have to depend just on the OEM. All critical parts on a FabX are

generic &

easily

available from 3rd parties. This makes FabX economically the Cheapest 3D Printer in

terms of

long-term OpEx.

A Couple of Examples...

The toolhead in the FabX is the E3D Lite6, the most popular hotend, very commonly available with 3rd parties. Just in case, you’re willing to upgrade your hotend to a different make, a drop-in replacement for E3D Lite6 or V6 from another brand would still fit & function.

Another great example is the choice of Motherboard which supports removable stepper drivers. If, in the chance a motor gets too hot & fries up a driver, a replacement would cost ~150 INR (2 USD), compared to replacing the whole motherboard in most other 3D Printers with integrated drivers, costing ~3K INR.

The Gantry! The FabX Pro series uses an expensive H Bot Gantry with Industrial

Grade

Rails whereas the FabX Lite Series 3D Printers use a simple Cartesian System

moving

on softrods & bush bearings - This is how most popular 3D Printers are built.

The Hotend! The FabX Pro series uses an E3D v6 with temperatures reaching uptown

295

°C, whereas the FabX Lite Series 3D Printers use an E3D Lite6 which as a Teflon

lining inside making it super smooth for PLA.

Yes, FabX supports all 1.75 mm filaments - a general advisory is to not go for cheap quality filaments.

General rule of the thumb - Manufacturing & Functional defects are covered. Physical damages, Wear & Tear would not be covered. Further improper usage like clogged nozzles due to poor quality filaments or wrong temperature settings will not be covered.