Top-Rated 3D Printing Services

Manufacture Parts Super Fast...

- India's #1 Maas Platform

- Wide Range of Materials

- No Quantity Cap - Starts 1 Unit

Need further assisstance? Contact Us.

Need further assisstance? Contact Us.

India's 1st and only Instant Automated MaaS (Manufacturing as a Service) platform

Upload the Files in

STL Format

Select the necessary material

and parameters

Parts will be printed and delivered

to your door sep

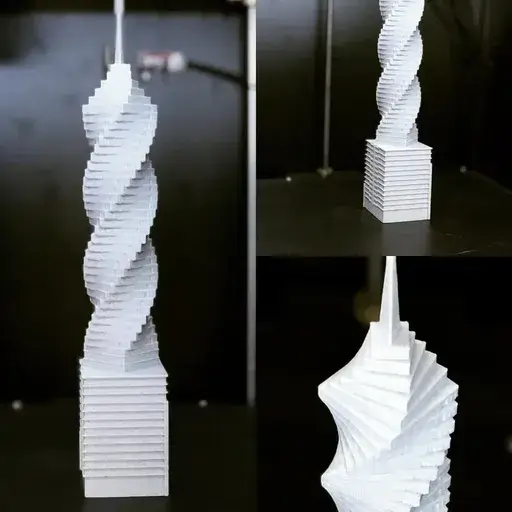

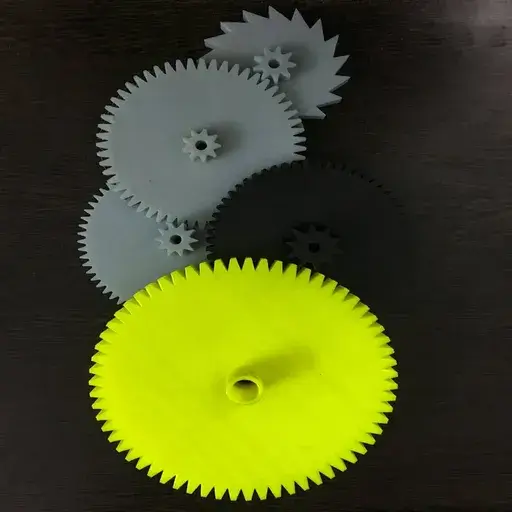

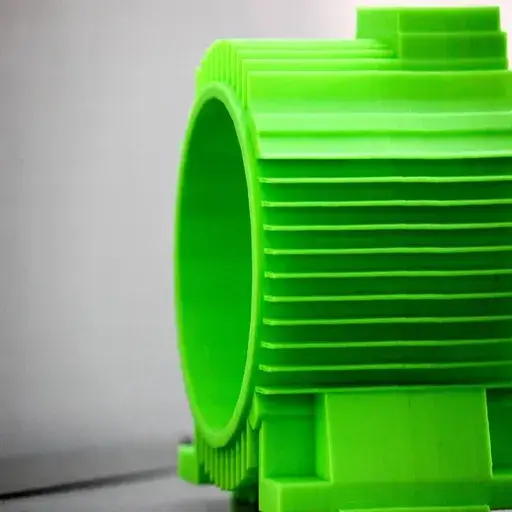

3Ding is a leading provider of 3D Printing Services, with a wide range of services that can help businesses and individuals bring their ideas to life. They use the latest technology and the best materials to create high-quality prototypes, models, and end-use products.

Experienced Designers

Quality Output

Communication and collaboration

Affordable Price

Fast Turnaround

Advanced Technology

"Excellent service! High

quality

prints and very prompt delivery. The 3D Printing Team is very supportive. The

best place to get your parts printed if you want a hassle free experience.

5/5, Would recomend the place to others."

Chennai

"They not only provide good quality 3D

printed parts but also good support in modifying the files, If there’s any

issues. People like me who are in budget and who can't afford a 3D printer can use this

service.

Overall Good Quality with great support."

Hyderabad

"Great Quality 3D Prints! I tested their 3D Printing Services by orderin a remote holder that fits on the tripod leg of my astronomy gear. Not only did the print turn out well, but the entire process was also handled very professionally, the package dispatched on time, and queries answered politely."

Astronomy Enthusiast