The Original Prusa i3 MK3S+ is a reliable and affordable 3D Printer that offers high-quality printing. With its large build volume and advanced features, this printer is perfect for both beginners and advanced users. Order yours today and experience the convenience of 3D Printing at home

The Original Prusa i3 MK3S+ 3D Printers comes with Large Build Volume and Heated Bed, Advanced Filament Sensor and Power Panic, Multi-Material Printing and Removable Magnetic Bed, Print Speed and Precision, User-Friendly LCD Screen and Navigation, High-Quality Printing at an Affordable Price, Versatile and Reliable Printing, Easy to Use and Customize, Continuous Improvement and Support, Versatile and User-Friendly, Reliable and Supported by a Community.

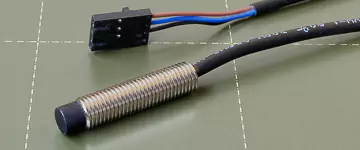

A high-quality sensor is included in the SuperPINDA probe to enable fully automatic mesh bed levelling. Before each print, the printer makes a virtual heightmap of the print area by probing the bed several times. The first layer is always precise thanks to this process.

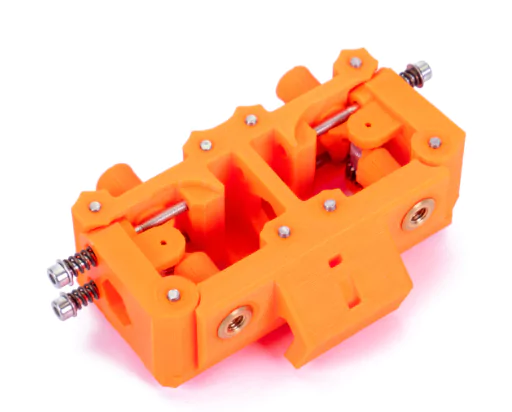

For the premium bearings on the Y-axis, the MK3S+ has a new set of metal clips. The X-axis belt tensioning mechanism was redesigned, and the plastic components at the X-end were strengthened. A change was made to the extruder's filament path to better accommodate flexible filaments.

The printed object can be easily removed from the print surface thanks to spring steel sheets, which are low maintenance. To meet your needs when printing from a variety of different materials—the majority of which don't call for any specialised separation layers or surface preparation—we offer three different types of print surfaces: smooth, textured, and satin.

An aluminium extrusion Y-axis assembly is a feature of the MK3S+. The MK3S+'s milled dural frame makes it stable, rigid, and simple to put together. The MK3S+ can print high-quality objects up to 210 mm in height when used with our custom extruder with Bondtech gears and the E3D V6 hotend.

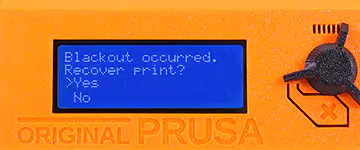

Do you worry that a blackout will obliterate your 48-hour print? No need to worry; the MK3S+ can handle that. The printer can fully recover from the power outage and pick up where it left off with printing. The heatbed and extruder heating are turned off when there are power outages, and the last known location is also saved.

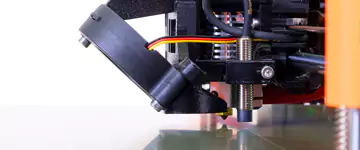

The improved extruder from the MK3S is further improved by the MK3S+. A trustworthy trigger system is used by the integrated filament sensor to determine whether a strand of filament has been inserted into the extruder. It is resistant to mechanical wear and can detect any filament type and colour.

The SuperPinda probe enables the MK3S+ to use the Mesh Bed Leveling procedure to correct for minute flaws in the print sheet as well as irregularities brought on by the assembly and stacking of different parts' manufacturing tolerances. It's quick and simple to create a first layer that looks fantastic.

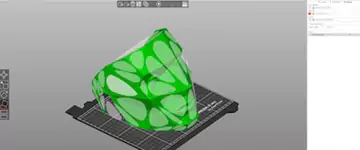

Our in-house created and thoroughly tested multiplatform slicer includes profiles for all of our 3D Printers as well as a variety of filaments. You can quickly convert your 3D models into print files using the built-in tools such as organic supports, cutting, automated object distribution, ironing, and many others.

The MK3S+ is completely compatible with a variety of different kinds of materials. The MK3S+ can handle a variety of tasks, whether you want to print something for fun using PLA and flexible materials or you need to create durable prototypes using PETG, ASA, Polycarbonate, and Polypropylene.

We create firmware for every one of our 3D Printers and thoroughly test each new version before making it available. Our machines are fully equipped with practical features like print sheet profiles, automated calibration, mesh bed levelling, advanced diagnostics, remaining print time estimation, Octoprint support, and more thanks to ongoing development and frequent updates.

Build Volume

25×21×21 cm

Layer height

0.05 - 0.35 mm

Nozzle

0.4mm default, wide range of other diameters/nozzles supported

Filament diameter

1.75 mm

Maximum travel speed

200+mm/s

Max heatbed temperature

120 °C / 248 °F

Maximum nozzle temperature

300 °C / 572 °F

Extruder

Direct Drive, Bondtech gears, E3D V6 hotend

Print surface

Removable magnetic steel sheets(*) with different surface finishes, heatbed with cold corners compensation

Printer dimensions (without spool)

7 kg, 500×550×400 mm; 19.6×21.6×15.7 in (X×Y×Z)

Power consumption

PLA settings: 80W / ABS settings: 120W

Supported materials

Wide range of thermoplastics, including PLA, PETG, ASA, ABS, PC (Polycarbonate), CPE, PVA/BVOH, PVB, HIPS, PP (Polypropylene), Flex, nGen, Nylon, Carbon filled, Woodfill and other filled materials.