The Bambulab P1S set the benchmark for speed, reliability, and print quality, becoming the top choice for makers and print farms worldwide. The new Bambulab P2S 3D Printer elevates that legacy with advanced 2nd-generation technology, refined user experience, and superior performance. Built on years of real-world testing and community insights, the P2S delivers the consistency, precision, and dependability that professionals and creators count on.

Print tough, industrial-strength materials like Nylon, ABS, PET-CF, and more. Designed for professionals, it enables the creation of durable end-use parts and functional prototypes.

The P2S introduces a redesigned interface powered by a new processor and a vibrant 5-inch touchscreen. Experience smoother navigation, clearer visuals, and guided workflows that make printing effortless.

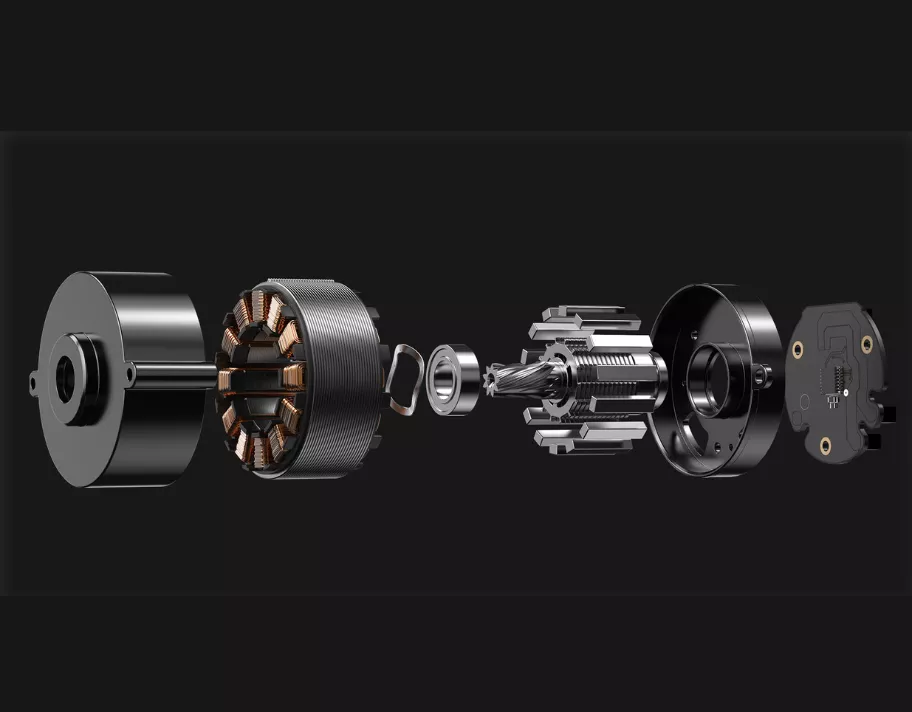

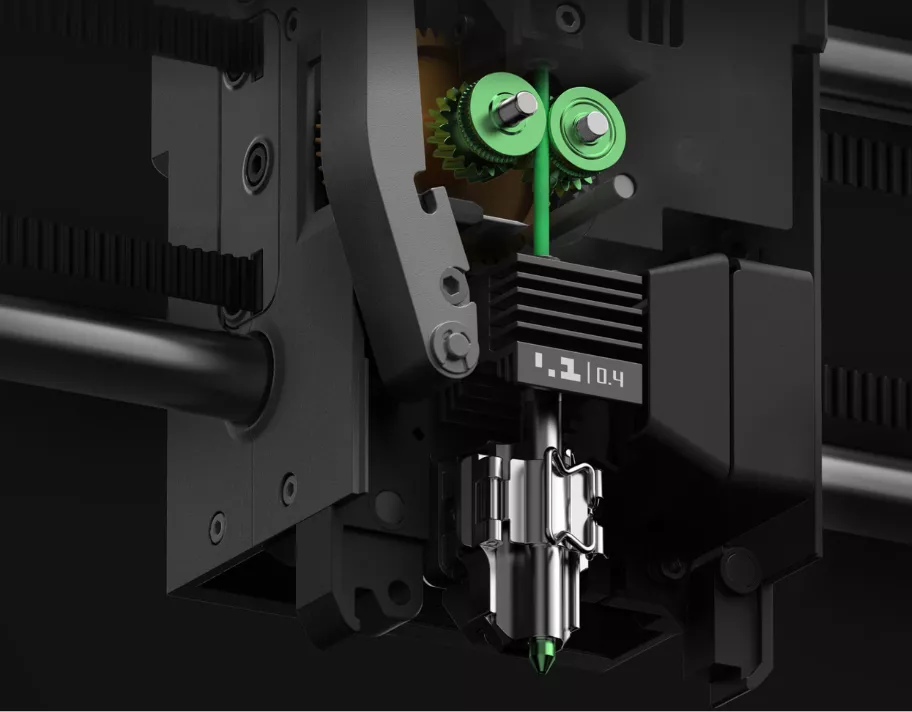

The new PMSM servo extruder delivers up to 8.5kg of extrusion force, with 20 kHz real-time feedback to detect clogs and grinding instantly.

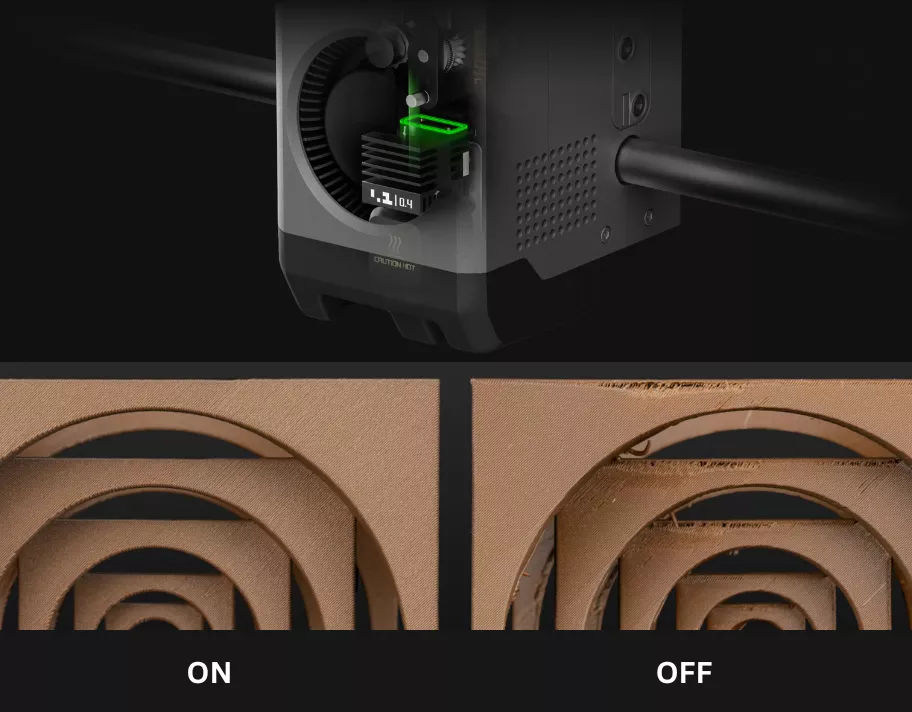

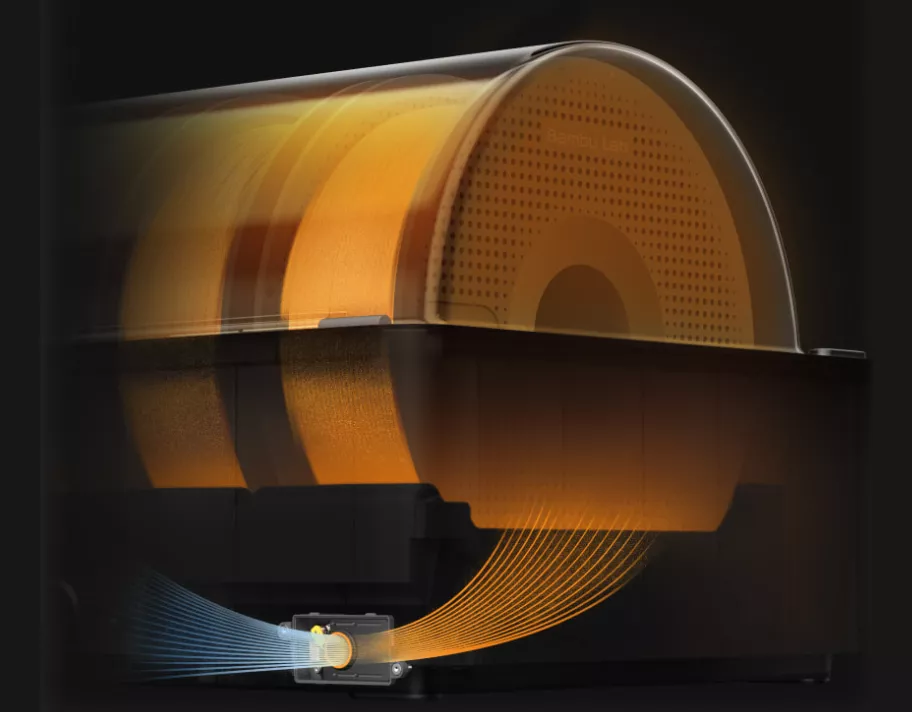

A high-frequency eddy current sensor measures and corrects flow in real time, ensuring smooth, consistent extrusion for every model.

For low-temp materials, the P2S pulls cold external air to prevent overheating and ensure perfect overhangs.

For engineering filaments, it seals the chamber to reach 50°C, maintaining optimal conditions for high-performance materials.

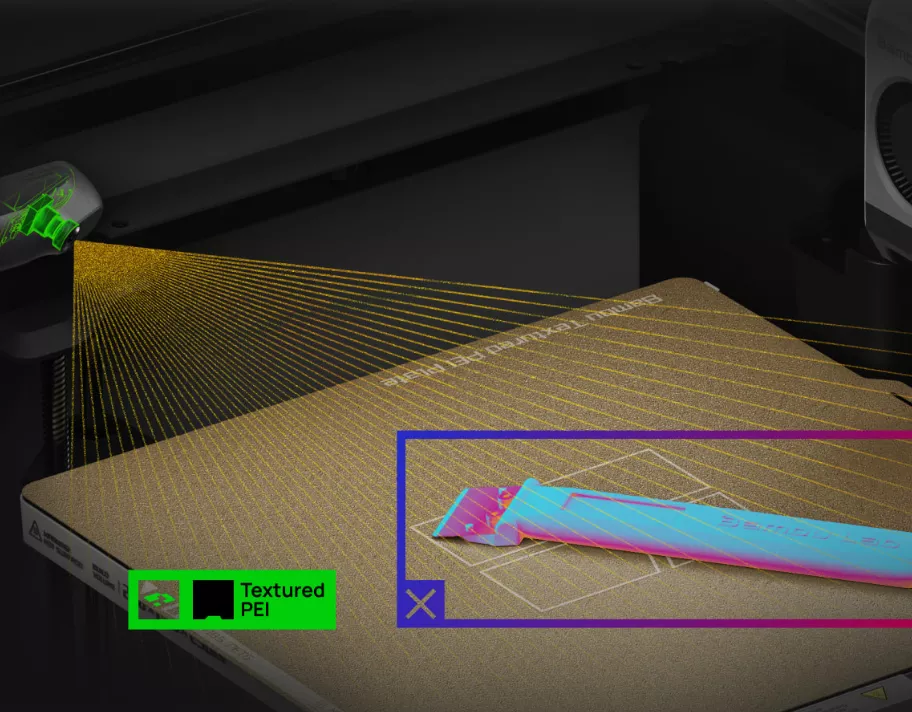

The onboard NPU detects:

Your prints stay safe even when you’re away.

A one-clip hotend system removes the entire nozzle and heatsink assembly no cables, no tools, no mistakes.

With upgraded LED lighting, a high-frame-rate 1080p camera, and dual-band Wi-Fi, remote monitoring is smoother and clearer than ever.

Hardened steel extruder gears + hardened steel nozzle = long-term durability for carbon-fiber and glass-filled materials.

With upgraded LED lighting, a high-frame-rate 1080p camera, and dual-band Wi-Fi, remote monitoring is smoother and clearer than ever.

The P2S pairs seamlessly with the AMS 2 Pro for:

Printing Technology

Fused Deposition Modeling

Body

Build Volume (W*D*H):

Single Nozzle Printing: 325*320*320 mm³ (Left)

Single Nozzle Printing: 305*320*325 mm³ (Right)

Dual Nozzle Printing: 300*320*325 mm³

Total Volume for Two Nozzles: 330*320*325 mm³

Chassis: Aluminum and Steel

Outer Frame: Plastic and Glass

Physical Dimensions

Physical Dimensions: 492*514*626 mm³

Net Weight: 32.5 kg

Toolhead

Extruder Gear: Hardened Steel

Nozzle: Hardened Steel

Max Nozzle Temperature: 350 °C

Supported Nozzle Diameter: 0.2 mm, 0.4 mm, 0.6 mm, 0.8 mm

Filament Cutter: Built-in

Filament Diameter: 1.75 mm

Extruder Motor: Bambu Lab High-precision Permanent Magnet Synchronous Motor

Heatbed

Build Plate Material: Flexible Steel Plate

Included Build Plate Type: Textured PEI Plate

Supported Build Plate Type: Textured PEI plate, Engineering Plate

Max Heatbed Temperature: 120 °C

Speed

Max Speed of Toolhead: 1000 mm/s

Max Acceleration of Toolhead: 20,000 mm/s²

Max Flow for Hotend: 40 mm³/s (Test parameters: 250 mm round model with a single outer wall; Bambu Lab ABS; 280 °C printing temperature)

Chamber Temperature Control

Active Chamber Heating: Supported

Max Temperature: 65 °C

Air Purification

Pre-filter Grade: G3

HEPA Filter Grade: H12

Activated Carbon Filter Type: Granulated Coconut Shell

VOC Filtration: Superior

Particulate Matter Filtration: Supported

Cooling

Part Cooling Fan: Closed Loop Control

Cooling Fan for Hotend: Closed Loop Control

Main Control Board Fan: Closed Loop Control

Chamber Exhaust Fan: Closed Loop Control

Chamber Heat Circulation Fan: Closed Loop Control

Auxiliary Part Cooling Fan: Closed Loop Control

Toolhead Enhanced Cooling Fan: Closed Loop Control

Supported Filament Type

PLA, PETG, TPU, PVA, BVOH, ABS, ASA, PC, PA, PET, PPS; Carbon/Glass Fiber Reinforced PLA, PETG, PA, PET, PC, ABS, ASA, PPA, PPS

Sensor

Live View Camera: Built-in; 1920*1080

Nozzle Camera: Built-in; 1920*1080

BirdsEye Camera: Built-in; 3264*2448 (Equipped with Laser Edition)

Toolhead Camera: Built-in; 1600*1200

Door Sensor: Supported

Filament Run Out Sensor: Supported

Filament Tangle Sensor: Supported

Filament Odometry: Supported with AMS

Power Loss Recovery: Supported

Electrical Requirements

Voltage: 100-120 VAC / 200-240 VAC, 50/60 Hz

Max Power*: 1800 W@220 V / 1250 W@110 V

Typical Power: 200 W@220 V / 200 W@110 V (Single Nozzle Printing PLA)

Working Temperature

10 °C–30 °C

Electronics

Touchscreen: 5-inch 720*1280 Touchscreen

Storage: Built-in 8 GB EMMC and USB Port

Control Interface: Touchscreen, mobile App, PC App

Motion Controller: Dual-core Cortex-M4 and Single-core Cortex-M7

Application Processor: Quad-core ARM with NPU

Software

Slicer: Bambu Studio

Supports third-party slicers which export standard G-code, such as Super Slicer, PrusaSlicer and Cura, but certain advanced features may not be supported.

Supported Operating System: MacOS, Windows, Linux

Network Control

Ethernet: Not Available

Wireless Network: Wi-Fi

Network Kill Switch: Not Available

Removable Network Module: Not Available

802.1X Network Access Control: Not Available

Wi-Fi

Operating Frequency: 2412 - 2472 MHz, 5150 - 5850 MHz (FCC/CE) • 2400 - 2483.5 MHz, 5150 - 5850 MHz (SRRC)

Wi-Fi Transmitter Power (EIRP): 2.4 GHz: <23 dBm (FCC); <20 dBm (CE/SRRC/MIC)

5 GHz Band1/2: <23 dBm (FCC/CE/SRRC/MIC); 5 GHz Band3: <30 dBm (CE); <24 dBm (FCC); 5 GHz Band4: <23 dBm (FCC/SRRC); <14 dBm (CE)

Wi-Fi Protocol: IEEE 802.11 a/b/g/n