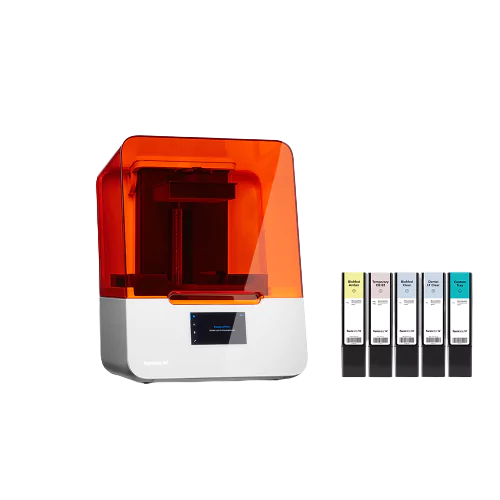

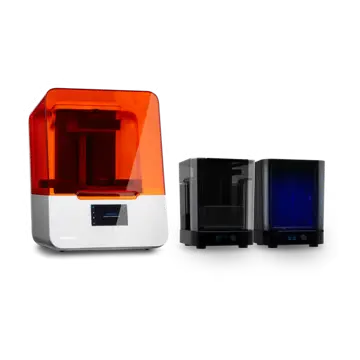

The Form 3B is a cutting-edge desktop 3D Printer designed for biocompatible materials. Faster processes are only a few clicks away because to our accurate, dependable ecosystem, which removes the guesswork from dental manufacturing. Create high-quality components with minimal effort and affordable expenses. With verified workflows that have been examined by dental specialists from various professions and disciplines, Low Force StereolithographyTM technology helps the Form 3B achieve speed, dependability, quality, and ease of use.

With a bottom made of white plastic, the upper body casing is transparent-orange in hue. Form 3B can be distinguished from Form 3 by its white plastic bottom case as opposed to Form 3's black bottom case.

Like Form 3, Form 3B employs Low Force Stereolithography (LFS), a cutting-edge technique that uses a flexible resin tank to lessen the peel pressures on the layers being printed, delivering precise and durable products.

The Printer's build volume, which is 145 x 145 x 185 mm, is sufficient for Printing surgical guides for dental procedures as well as dentures.

In order to free up medical professionals' attention from having to troubleshoot print issues, Form 3B has upgraded gear that consistently produces trustworthy prints. Form 3 offers a broad range of dental and medical materials, enabling the integration of 3D Printing into the dental industry.

Slicing, automatic support creation, establishing all print settings, including layer height, and choosing material profiles are all possible with Formlabs' own proprietary Pre-Form software. STL and OBJ file formats are supported by Pre-Form. Real-time monitoring features on the Formlabs dashboard include print status, pause/stop, and information gathering for maintenance.

The Form 3B comes with a 5.5" LCD touch screen control with USB, Ethernet, and Wi-Fi networking options. The Formlabs dashboard provides the option to enable SMS/Email alert notifications.

Spend less time and money while producing parts you can be pleased to provide. Formlabs offers unmatched dependability, quality, and usability, with processes that have been evaluated by a group of dental specialists for effectiveness.

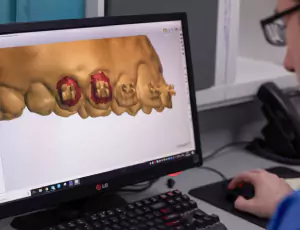

Utilize an intraoral scanner to digitally capture the patient's anatomy. Send scans to a design station or the lab with a digital prescription.

In CAD software, where virtual design is done, import scan data.

Send the designed CAD files simply to a Formlabs printer by importing them into PreForm print preparation software for print setup.

Clean, dry, and post-cure printed pieces. These components can then be injected into a patient or used to create a variety of indications.

Build Volume

145 × 145 × 185 mm

Layer Thickness

25-300 microns

Operating Temperature

Auto-heats to 35 °C ,

Auto-heats to 95 °F

Software

PreForm

Resin Types

Standard Resins, Surgical Guide Resin, Elastic Resin, Tough Resin

Material

Photopolymers

Laser Specifications

1 Light Processing Unit, EN 60825-1:2007 certified, Class 1 Laser Product, 405 nm wavelength, 250 mW power

Connectivity

WIFI, Ethernet and USB

Laser Spot Size (FWHM)

80 microns