Flashforge Guider 3 is the Next generation lightweight 3D Printer. Experience the advanced features of Guider 3, a cutting-edge 3D Printer designed for the new generation. With an enhanced print space ratio and hassle-free nozzle replacement, it offers unparalleled convenience. Equipped with dual build plate options, a quick-disassembly nozzle, HEPA 13 air filter, and remote monitoring capabilities, Guider 3 ensures an intelligent and seamless printing experience for educational institutions, small businesses, and individual users. Embrace cost-effective small batch production with Guider 3, your ultimate choice.

The lightweight equipment and powerful production management system ensure stable and continuous printing 24 hours a day, seven days a week during the production and development process, making it suitable for multi-scenario applications.

Power Outage Recovery System

It can save the printing state in the event of a power outage and resume printing once the power is restored.

Integrated Equipment Management System

In small batch production, our FlashPrint 5 slicing software allows for multi-machine joint control and integrated device management.

Monitoring the Printing Process in Real Time

With the camera, the printing process and status can be easily monitored in real time via the FlashPrint 5 and UI interfaces.

The Open Material System

The 320°C high-temperature extruder is compatible with ABS / PLA / PC / PA / HIPS / ASA / PETG / PA-CF, among other materials, and is suitable for a wide range of applications.

Guider 3 was created specifically for small batch production applications. The lightweight and compact machine structure, simple and powerful management system, and quick and efficient delivery capability ensure continuous small batch manufacturing in a variety of scenarios, as well as low-cost and simple production methods.

Lightweight and compact design

(10% weight loss)

Printing Speed is Excellent

(250mm/s)

Effortless Use

24/7 Stable Printing

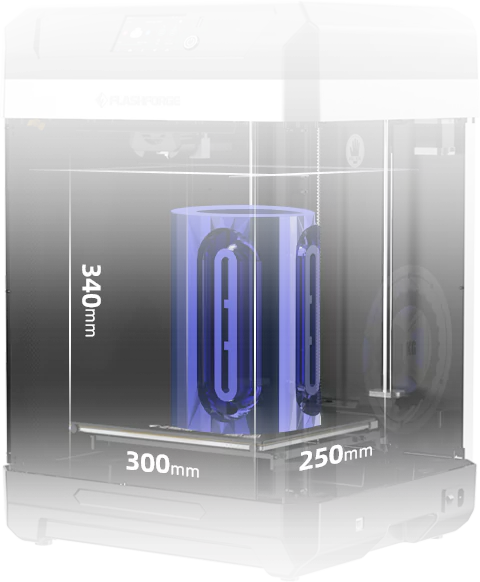

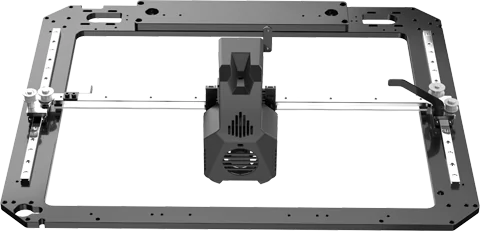

The new machine structure design increases the equipment's internal space utilisation rate, realises the expansion of the build volume while requiring less space from the equipment, and provides a flexible layout for the production line.

Aluminium is used throughout the entire frame, and ABS and acrylic sheets, which are both strong and lightweight, are used in the enclosure to realise the lightweight design from the inside out and ensure stable printing.

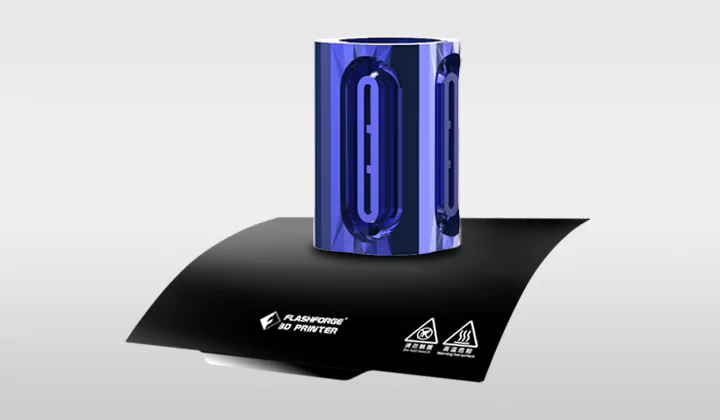

Glass platform and flexible steel plate platform are two of Guider 3's platform options. Users can choose different filaments individually based on their needs when printing them, which makes it appropriate for a variety of printing scenarios.

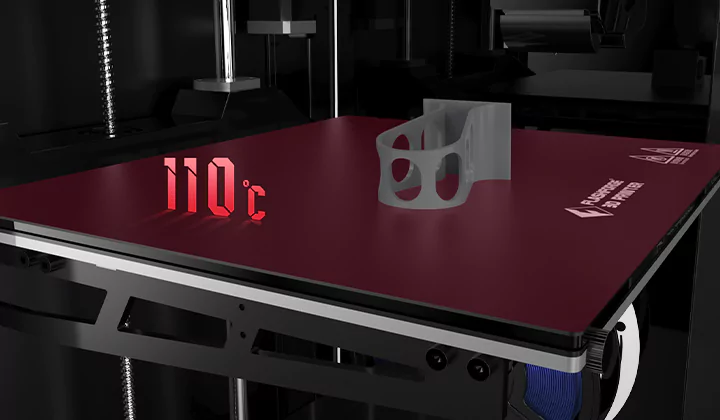

Rapid replacement within 30 seconds; uniform 110°C heating throughout the entire format, providing better printing results

Glass platform: Model removal with a shovel or scraper is quick and simple thanks to the flat, smooth surface, which saves time and labour.

Platform made of a flexible steel plate: The magnetic removable platform can be bent easily, making it simple to remove big models.

CoreXY Structure for Rapid

Production

Guider 3

supports high-speed and low-noise printing, which reduces printing

time, guarantees stable printing, and results in an efficient printing experience. It also

contributes to efficient workflow and meets the rapid delivery demands of customised markets.

More Convenient Upgraded Leveling System

Guider 3

Levelling is essential to the success and calibre of printing because it is the first step in

the printing process. In order to ensure your levelling operation in all directions, Guider 3

optimises the auxiliary levelling and automatic levelling system.

In order to achieve automatic levelling, the high-sensitivity and inductive proximity sensor

detects and records the horizontal platform's initial flatness data before intelligently

adjusting the platform height through the Z-axis while printing.

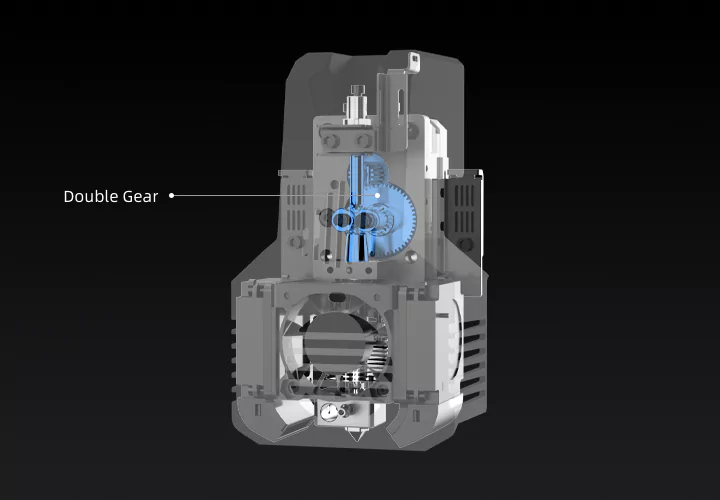

The double-gear extrusion structure design, suitable for various filaments, increases the filament feeding force by 150% and results in fewer clogging problems, not inferior at all for various application requirements.

The quick-release nozzle, which comes in a variety of diameter options, is simple to replace and maintain and can be used for a variety of purposes.

Self-equipped Maintenance Assistant: The outfitted maintenance assistant offers fixes for typical printing issues, reduces communication time, and achieves effective maintenance.

Filament Detection

For the purpose

of identifying filaments in an abnormal state, Guider 3 has a filament detection sensor. The

machinery will automatically stop if the filament is exhausted or clogged and alert you to the

issue, effectively preventing damage to the printed part or nozzle, saving electricity, and

reducing material waste. After the issue is fixed, printing can resume when the filament is

finished.

Air Filtration

The dust, odour, and

particles produced during the printing process can be efficiently filtered by a HEPA air filter

system, ensuring a healthy and secure working environment.

Sleep Mode

When a piece of

equipment is inactive for a while, it will automatically go into sleep mode, at which point the

screen turns black and the lights are turned off, ensuring low energy consumption when in use at

night.

Auto Shut-down

The printer will

automatically shut off once it has finished printing, enabling unattended, safer, and

energy-saving operation.

Small Studio

Educational Institution

Small laboratory/factory

Extruder Quantity

1

Printing Precision

±0.15mm or 0.002mm/mm

Positioning Accuracy

X/Y-axis 0.011 mm;

Z-axis 0.0025 mm

Layer Thickness

0.05 ~ 0.4 mm

Build Volume

300 x 250 x 340mm

Nozzle Diameter

0.4 (0.4/0.6/0.8)mm

Nozzle Type

Stainless steel nozzle

Printing Speed

10 ~ 250mm/s

Maximum Extruder Temperature

320 ℃

Maximum Platform Temperature

110 ℃

Nozzle Temperature

≤300°C

Hotbed Temperature

≤110°C

Supported Filament

ABS / PLA / PC / PA / HIPS / ASA / PETG / PA-CF / PLA-CF / PETG-CF / PETG-GF

Power Supply

AC100-240V / DC24V / 20.8A, 650W

Device Size

496(L) * 436(W) * 696(H) mm

Packaging Size

585(L) * 530(W) * 760(H) mm

Slicing Software

Flashprint

Voltage

Input AC 115V-230V

Output DC 24 V

Printing Bed

Flexible steel plate platform / Glass platform

Input / Output File Format

Input: 3MF/ STL / OBJ / FPP / BMP / PNG / JPG / JPEG File; Output: GX / G File / gcode

Printing Connection

USB Disk / Ethernet / Wi-Fi

Certification

CE / FCC / RoHS

Working Temperature

15-30℃

Compatible Operating System

Win xp / Vista / 7 / 8 / 10、Mac OS

Compatible Slicing Software

Slic3r / Cura (Need to set up)

Touch LCD Screen

4.3-inch

Close Design

Yes

Auxiliary Leveling

Yes

Filament Running Out Reminding

Yes

Replaceable Print Bed

Yes

Ultra Silence Design

Yes

Resume Printing

Yes

Remote Camera Watching

Yes

Wireless Wi-Fi

Yes

Ethernet

Yes

USB Stick Interface

Yes

Air Filter Net

Yes

Cloud

Yes