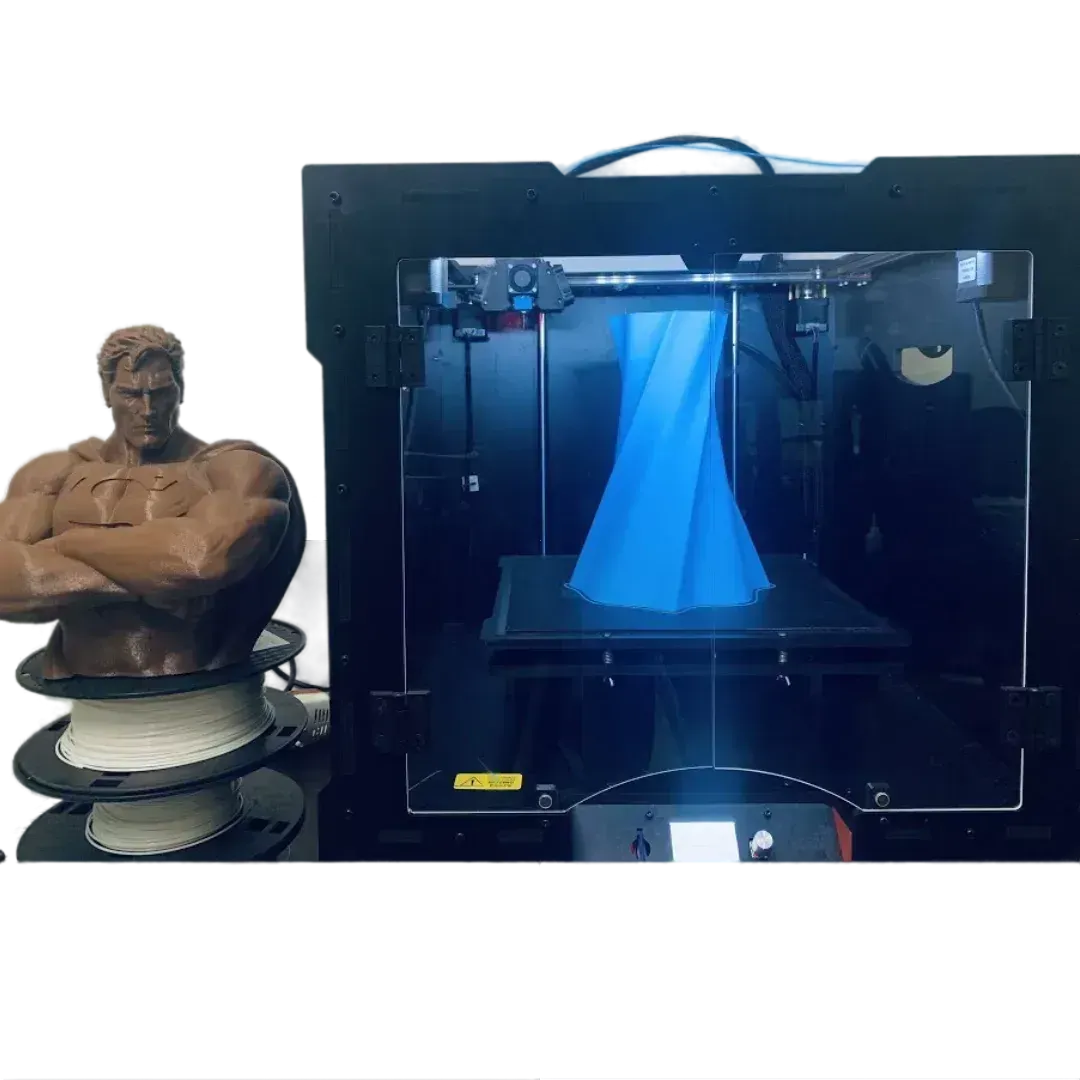

More than 15000 3D Printers Shipped Out.

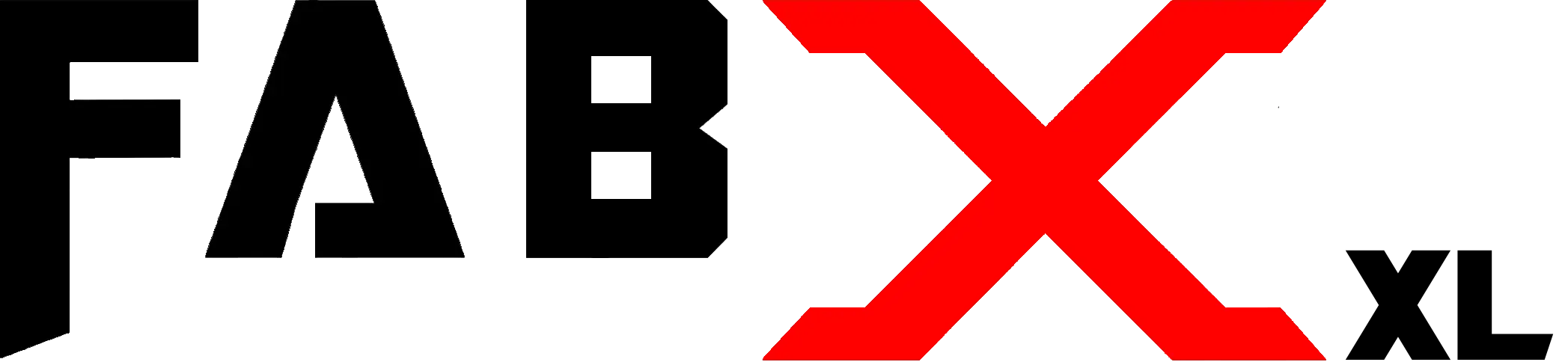

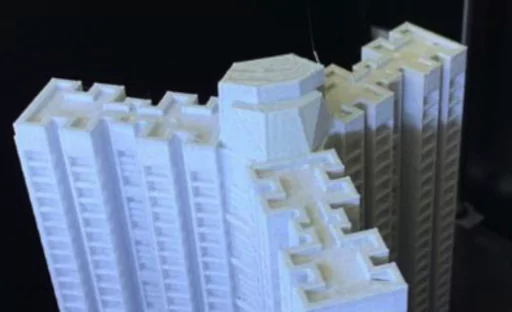

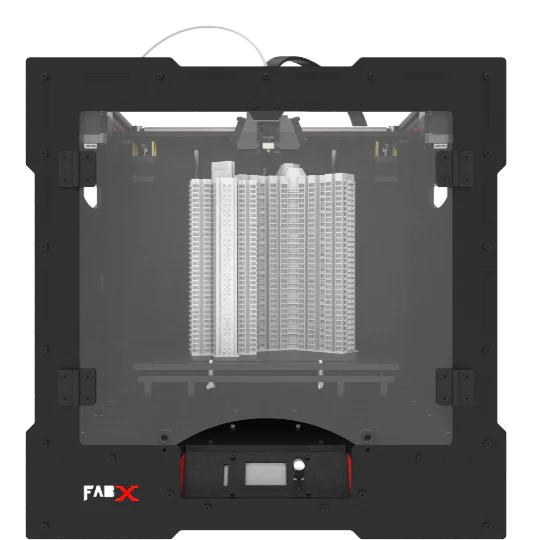

Equipped with Intuitive User Interface, Active Triple Cooling, Magflex Build Plate and other features, FabX XL is the most user friendly large size 3D Printer in the market. Built for the architects, model makers, designers and schools, FABX XL can be used by anyone who wants to print big with a very small learning curve. To put it simpler terms, if you can use a computer, you can use a FabX.

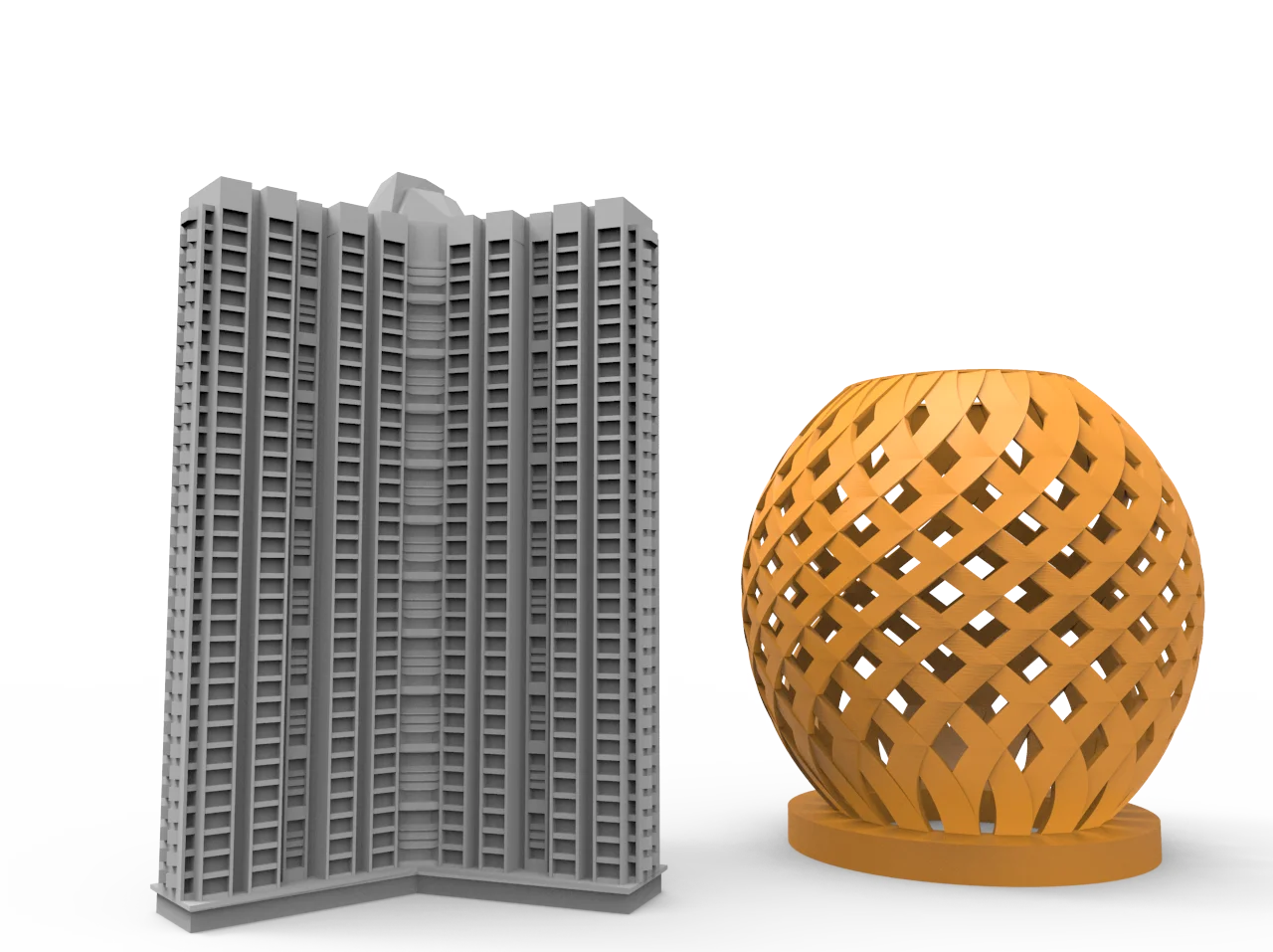

FabX XL 3D Printer comes with Extra Large size. Has Bigger build volume compared to other 3D Printers. Build volume of FabX XL is 270*270*300 mm3.

Design big and Print big with FabX XL 3D Printer. Also it increase the quality of Printing.

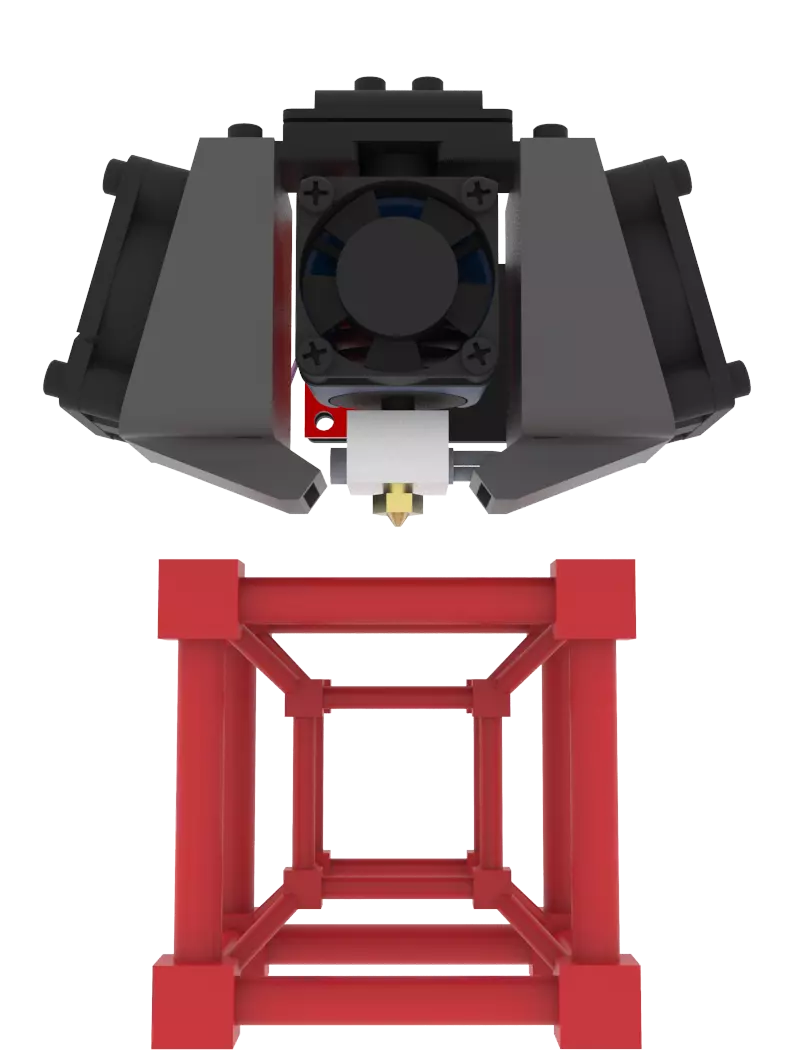

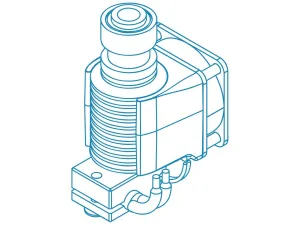

While the hotend fan prevents heat from seaping up & thus preventing clogs, the two other ducted fans provide rapid cooling, thus enabling the FabX XL to handle extreme bridging with minimal to no supports.

This also makes the FabX XL print High speeds with ease.

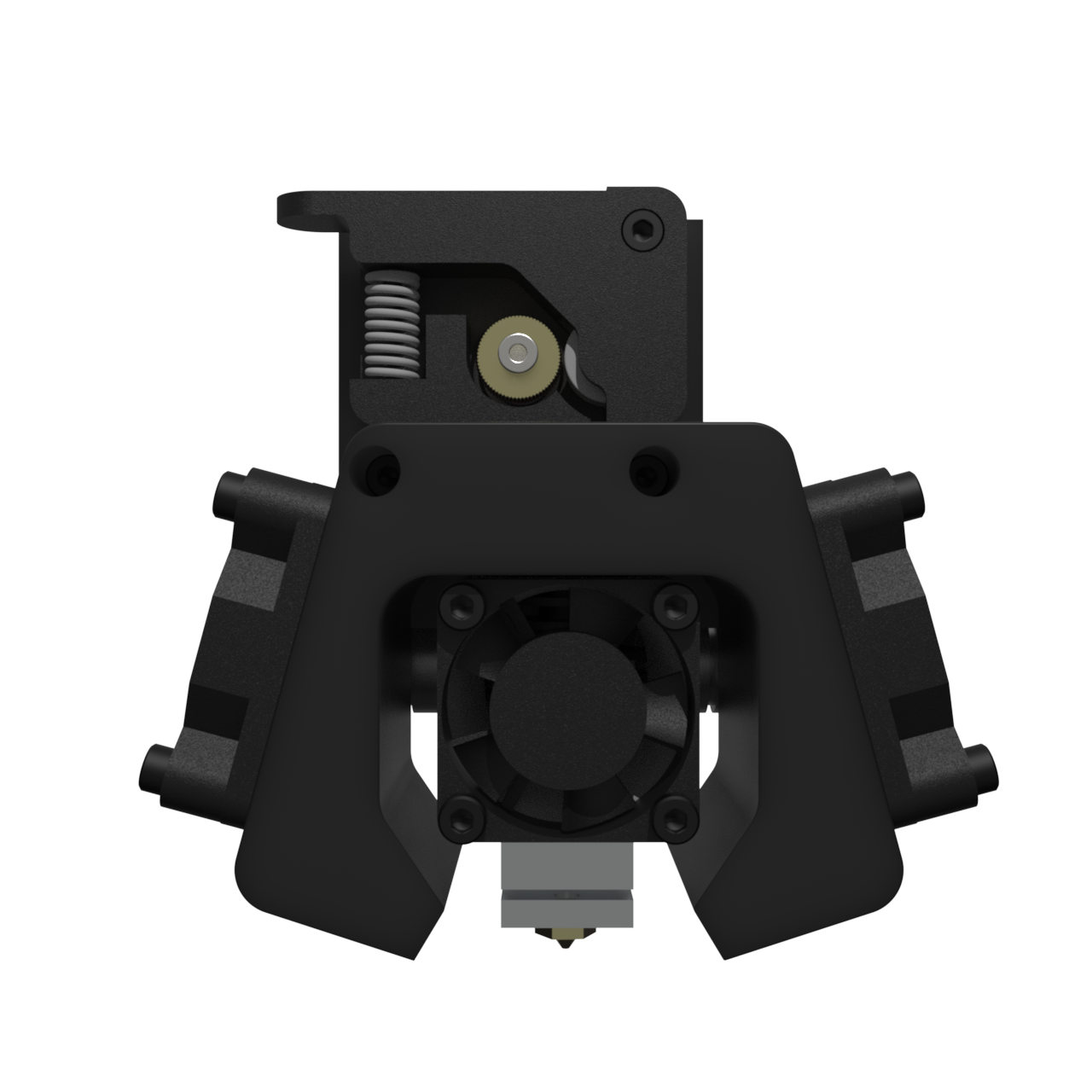

FabX XL is the only FabX to sport a direct drive feeder mechanism that enables high

precision 3D

Printing with negligible to zero vibrations at incredible accuracies.

Thus increasing the print quality of FabX XL significantly over the other FabX Series with

bowden feeder mechanism.

Defaulting a 0.4 mm nozzle means layer-heights upto less than 0.4 mm (let's say 0.35

mm).

Perfect for those super-quick draft-quality prints during your ideation stages.

...but, for those super slanty slopes or a fine output requirement, push the limits of

your

FabX & go down to 50

microns(0.05

mm)

per layer.

In the image is an actual 3D Printed moai statue in HIPS with 50 micron layers (Not a render).

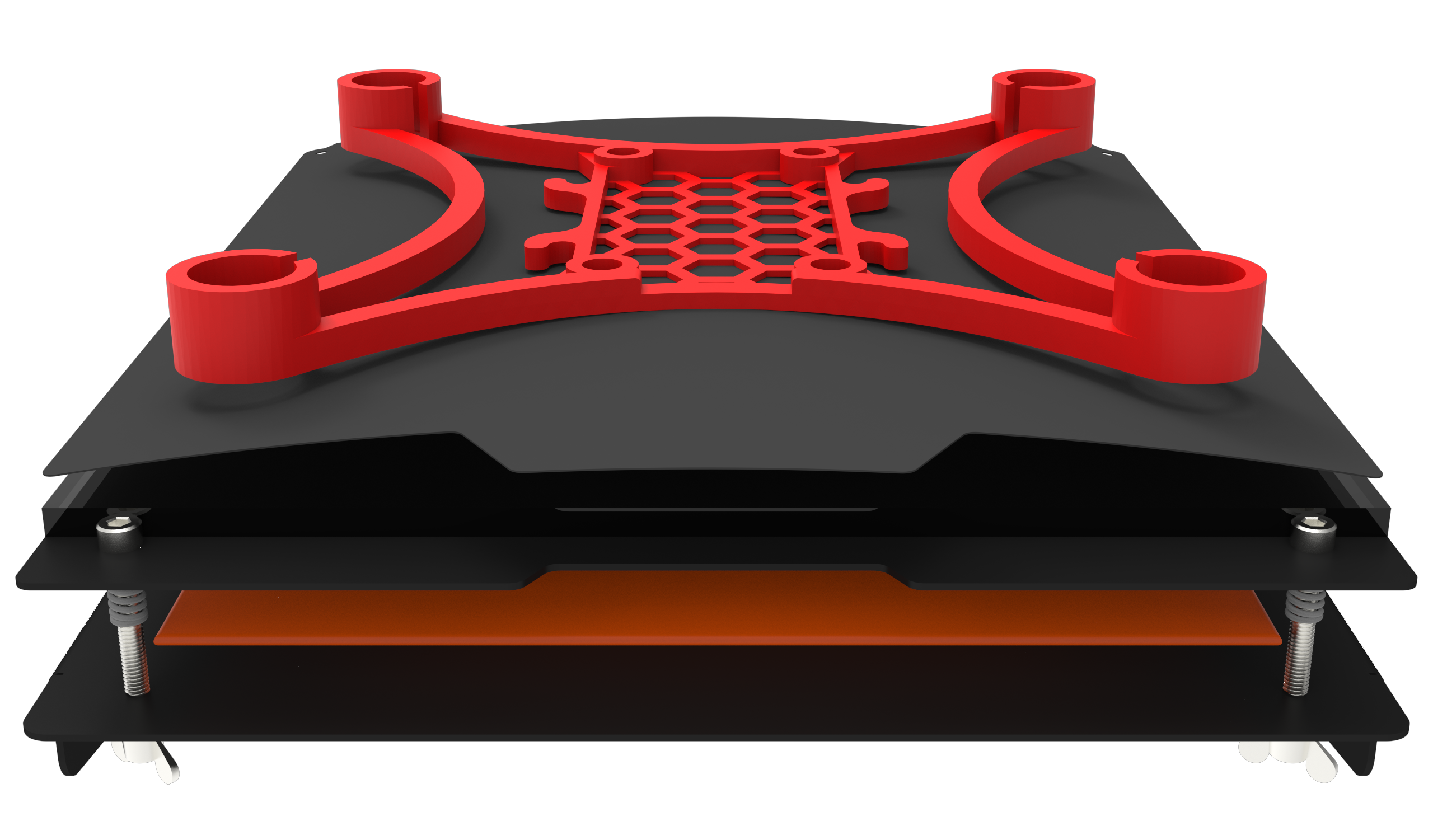

A non-contact optical limit switch homes your Z axis precisely,

in the range of 5 microns. 3 Points are all you need to level a plane &

the FabX Lite has them - Level it once with an assisted system when you

unbox your FabX (or transport it physically) & forget about levelling.

Get Perfect first layers every single print!

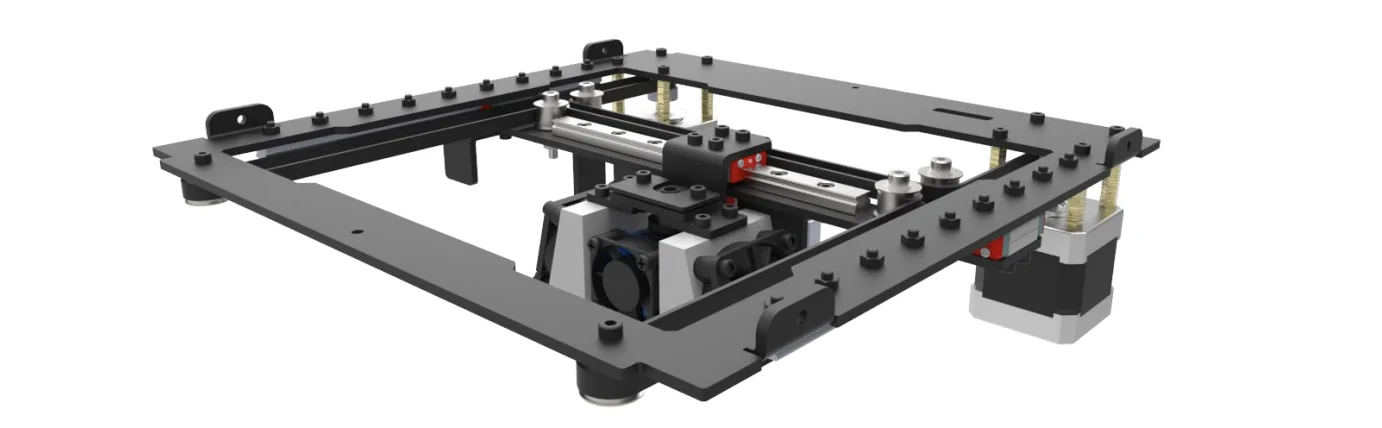

The FABX XL 3D Printer is built with an Engineering Grade Reinforced Fiber chassis, uniquely designed with a 2D Laser Cut Mechanism, keeping it light yet extremely robust.

The FabX Pro supports a huge list of Slicing Software. On the recommended list are Simplify3D, Cura, Prusa Slicer, SuperSlicer, Slic3r, MatterControl, the list goes on..

FabX Pro runs on the latest software Marlin 2.1

Recommended : Prusa Slicer

Unlike Most 3D Printers which remember the last known layer number, FabX 3D Printers remember & recover from the last known location of the extruder on the last known layer, reducing overlaps & hence a much precise recovery after a power loss.

Online Knowledge Base

Learning Modules

Call & Email Support

Extended Warranty @ 22.5% of MRP per Year.

Annual Maintenance Contract @ 12.5% of MRP Year.

Upto 3 Additional Years

Unlike no other 3D Printer in the market, the FabX XL packs a Homogenous.

E.g. the Y axis, though has two rails, both are mounted on a single laser cut Aluminium Sheet, making it impossible for an external error factor wit h respect to precision in that axis. Similarly, the z axis actuator is a homogeneous setup with no couplers, making no room for backlash or ply.

With

historical lifespan of the FabX 3D Printers ranging 5+ years & increasing, repairability is

an important

aspect & has been built into FabX 3D Printers right since the FabX 3 in 2016.

If & When

you need

spares, you don't have to depend just on the OEM. All critical parts on a FabX are

generic &

easily

available from 3rd parties. This makes FabX economically the Cheapest 3D Printer in

terms of

long-term OpEx.

A Couple of Examples...

The toolhead in the FabX is the E3D Lite6, the most popular hotend, very commonly available with 3rd parties. Just in case, you’re willing to upgrade your hotend to a different make, a drop-in replacement for E3D Lite6 or V6 from another brand would still fit & function.

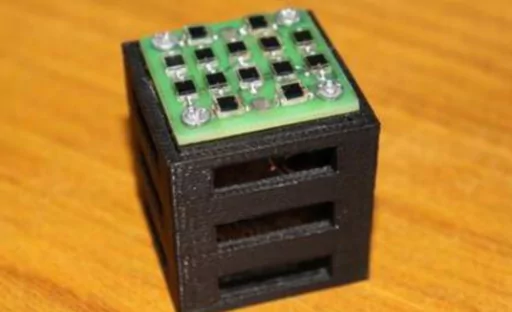

Another great example is the choice of Motherboard which supports removable stepper drivers. If, in the chance a motor gets too hot & fries up a driver, a replacement would cost ~150 INR (2 USD), compared to replacing the whole motherboard in most other 3D Printers with integrated drivers, costing ~3K INR.

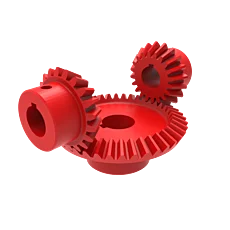

PLA is the most popular 3D printing material because it is the most familiar and easy to print. Environmentally friendly.

PLA+ Filament comes with additive boost and same features like PLA. PLA+ filament can provide a smoother finishing than PLA.

ABS Filaments can be applied in the actual world. Strong against impacts and capable of being in high-temperature environments.

A UV Resistant material, commonly used in Health-Care Appliances. And it is very popular filament, also Strong and Flexible.

HIPS Filament is a strong and durable. It is very easy to use in screen Printing, offset lithography, and flexography. Good impact Resistance.

TPE Materials among the top varieties of elastic and durable 3D Printing material in the market. can be used in a wide range of applications.

TPU is a flexible and plastic material, and Used in varoius industries. Making rubbery Tyres for Your robots or cases for your Phones?

PVA is popular as a support material because it’s Dissovles in Water. For those unique applications where you want a 3D Printed part dissolved.

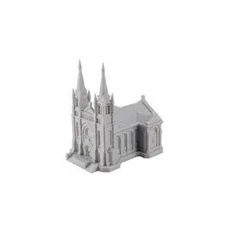

Marble PLA offers a beautiful output with a marble texture and polish. It is commonly utilised in the creation of architectural models and statues.

Wood PLA has a gorgeous output with a wooden texture and finish because it is made up of 80% PLA and 20% wood granule.

Easy to print

Smoother finish

Post Processing Friendly

UV Resistant

Strong and Durable

Top varieties of Elastic and Durable

Flexible Material

Dissovles in Water

Results beautiful output

Results gorgeous output

Build Volume

270*270*300 mm3

Layer Resolution

50 - 350 Microns

0.05 - 0.35 mm

Printing Temperature

Nozzle: 275

Max Volumertic Speed

15 mm3/s

Filament Diameter

1.75mm

Nozzle Diameter

Default - 0.4mm

Ineterchangable - 0.2mm to 0.8mm

Gantry

H-Bot

Connectivity

SD Card, USB Cable, Cloud3r (Opitonal - WiFi, Mobile Browser, USB Stick)

Positioning Precision

XY: 12 Microns

Z: 5 Microns

Operating Platforms

Windows/Mac OS

Input File Type

STL/OBJ/3MF

Output File Type

GCODE

Supported Materials

PLA ,PLA+ ,ABS ,PETG ,HIPS ,PVA ,TPU ,TPE ,Marble PLA ,Wood PLA ,Other PLA/PETG composites.

Power Consumption

PLA: ~100 Watts, ABS: ~230 Watts

AC Input

~230V, 50-60 Hz

Noise Level

< 50db

Extruder Type

Direct Drive

Active Triple Cooling

Max Travel Speed

200 mm/s

Chassis

Reinforced Fiber +

Metal Parts

Hotend

E3D Lite6, PTFE Lined, Max Temp: 250°C, 40 Watts.

Bed

AC Silicon Heater, Max Temp: 120°C, 150 Watts.

Build Surface

MagFlex 2.0, Magnetically Detachable, Textured, Flexible, Borosilicate Glass.

Slicing Software

PrusaSlicer (Recommended), Cura, Simplify3D, slic3r, SuperSlicer, Matter Control.

Shipping out over thousands of 3D Printers from the FabX Series, we’ve noticed that FabX XL is best suited for 3D Printing businesses, Architects, Real Estate Builders, Makerspaces, Model Making Service Providers, Product Designers, Interior designers, Additive Manufacturing Lab Setups, Schools. Especially with the spec and the price tag, FabX XL is the most ideal 3D Printer for Desktop Prototyping where the build requirements are less than 270*270*300 mm3

The FabX XL is probably the only domestic 3D Printer with it’s spec in it’s price category. For e.g. finding a Domestic 3D Printer has a build volume of 270*270*300 mm3, direct drive mechanism, Active Triple Cooling is difficult. The FabX XL does that.

If you can operate a computer, you can operate a FabX Pro, however,

understanding the concepts in-depth helps better. You might want to attend one

of our 3D Printing Workshops. A complimentary pass could be given on the

purchase of a FabX Pro.

Alternatively, we have a quick start video.

To get your first prints, it shouldn’t take you more than a 10-15 min learning. For an advanced level, it’ll take some experience with the 3D Printer and probably a few weeks learning.

Absolutely. A good amount of our customers who run successful businesses have started with a FabX. Though XL can only print with basic PLA and other composites, the ability of XL to print in large sizes has certainly attracted commercial buyers for the product as most large size models are printed using PLA and its composites.

Yes. You'll be provided with slicing software, sample files and a 250g filament spool to get started.

Yes, the FabX XL has a direct drive mechanism for feeding the filament. This allows soft and flexible materials like TPE, TPU to print well. However, you would highly recommend only experts to use flexible materials as the material can easily damage your hotend and nozzle if not used correctly.

The FabX XL comes with a 1 Year warranty - covers functionality aspects of the machine & not wear n tear, physical damage etc. Most of the machine design is modular. If there’s a minor part failure, a replacement would be shipped and instructions would be provided to fix. In case of major issues, depending on your location, an engineer could be sent or the product would be picked up by us remotely, for servicing.

We expect you to keep the machine clean and dust free. Cover it up when not using for longer periods. Do not try to load or unload filaments when the extruder is cold.

The FabX XL is capable of running 24*7. In our offices, the 3D Printers deployed for services, keep running back to back, sometimes for weeks together.

Yes. It’s compatible with cloud platforms like Octoprint, Astroprint etc. However you’ll have to procure a raspberry pi separately & install the OS yourself. This is not part of the package & such a service is not currently provided by us. By default, prints can be initiated on the FabX XL via USB or an SD Card. (Supplied with the machine).