Zortrax Endureal

An Industrial 3D Printer

An Industrial 3D Printer

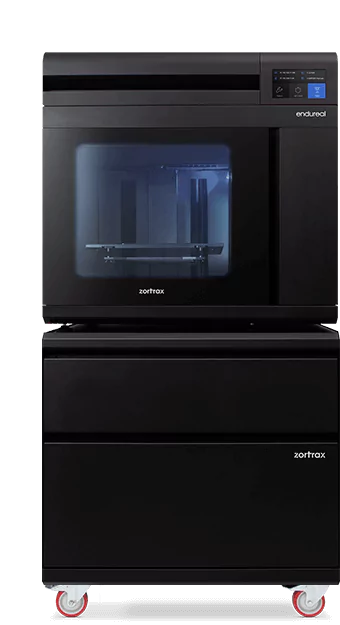

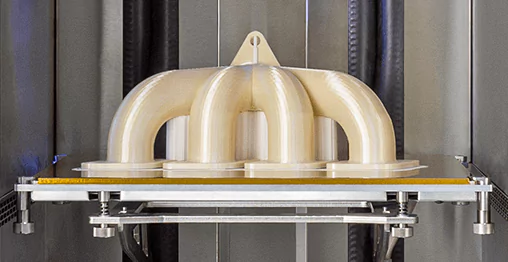

According to industry thought leaders, third generation 3D Printers are all about advanced thermal management that allows for efficient work with high-performance polymers. The temperature of the filaments in the Zortrax Endureal LPD Plus 3D Printer is tightly controlled at every stage of processing to achieve the highest precision and mechanical properties of the 3D printed parts.

To process demanding filaments, an advanced extruder can operate at temperatures as high as 480° C for extended periods of time.

To ensure the best thermal conditions for high-temperature materials, the temperature in the printing chamber can reach up to 200° C.

A build platform that can withstand temperatures of up to 220° C to ensure model stability.

Endureal includes an automatic annealing function that can be used after printing to achieve the best mechanical properties of high-temperature materials.

The thermally shielded extruder compartment is always kept at low temperatures to ensure continuous filament transmission.

Filaments are stored in a secure, closed environment at temperatures that are optimal for both the high performance and standard polymers with which Endureal is designed to work.

Endureal has a cutting-edge dual-extrusion system that can print high-temperature filaments with soluble support structures. To achieve the lowest possible thermal conductivity, the extruder components and filament cables are thermally shielded from the build chamber by an elastic insulator with pore size smaller than the mean free path of air particles. Endureal is designed to process difficult materials such as PEEK or CFR filaments, but it can also work with a variety of low-cost filaments such as Z-ULTRAT Plus, Z-NYLON, or Z-PCABS. Both single and dual-extrusion modes are supported by the Printer.

Endureal has an aluminum build platform that can reach temperatures high enough to process high-performance polymers. To ensure proper adhesion of all supported filaments, an easily switchable build plate made of ferritic steel covered with a PEI film is attached to the build platform. Model removal is made easier and faster with switchable build-plates, which is important in high-volume p

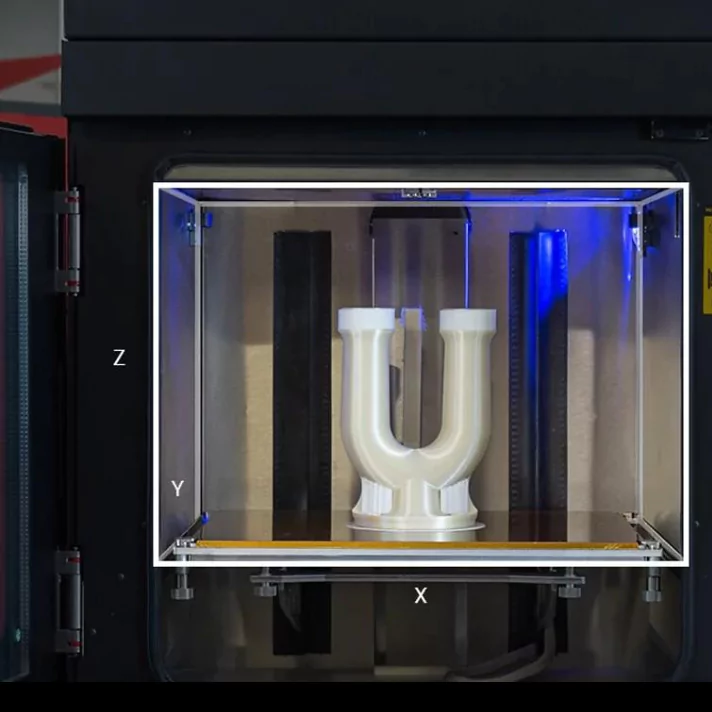

The build volume of 400 x 300 x 300 mm is sufficient to accommodate full-sized structural industrial components. Because of the ability to print soluble support, the majority of the build volume can be used by stacking models in batches arranged on top of each other.

Zortrax Endureal can be implemented just as easily as desktop-class 3D devices because it is a full-fledged industrial machine. Endureal is ready to work at maximum capacity from day one thanks to an intuitive user interface and software with carefully tuned settings predefined for each dedicated filament. The business continuity kit, which contains everything needed for quick and effective internal maintenance, further contributes to the ease of implementation when it comes to operating the Printer.

Over 30 built-in sensors in Zortrax Endureal work in real-time to ensure smooth operation in high-tech manufacturing and product development projects.

Blackout Response System

Resin 3D Printers can manufacture dental impressions, surgical guides, and interim crowns or bridges swiftly and affordably.

Monitored Printing Progress

A heat-resistant camera installed in the Endureal's printing chamber allows for remote monitoring of printing progress. The camera can stream live video and is built to withstand harsh conditions.

Advanced Filament Sensors

Separate sensors are constantly monitoring for events such as filament jamming or depletion. The Printer also monitors the weight of the filament spools to determine if there is enough material to complete the printing process.

Controlled Filament's Compartment

The compartment for filaments provides the best setting for keeping material spools. It has a moisture absorber installed, which is in charge of bringing the humidity down to levels suitable for highly hygroscopic materials.

Build volume

400 x 300 x 300 mm

Nozzle diameter

0.4 mm

Extruder

Dual material

Extruder cooling system

Two fans cooling the extruder, radial fan cooling the print

Hotend

High-temperature dual hotend

Platform

Heated; aluminum plate coated with PEI

Material sensors

2 x mechanical endstop, 2 x material weight sensor

Connectivity

Wi-Fi, Ethernet, USB

Operating system

Android

Processor

Quad Core

Touchscreen

7" IPS 1024 x 600

AC Input

120 V ~ 13 A 50/60 Hz

200 - 240 V ~ 9.5 A 50/60 Hz

Maximum power consumption

120 V - 1600 W

200-240 V - 2300 W

Software bundle

Z-SUITE

Supported input file types

.stl, .obj, .dxf, .3mf, .ply

Supported operating system

Mac OS Mojave and newer versions / Windows 7 and newer versions

Technology

LPD Plus (Layer Plastic Deposition Plus) advanced technology depositing melted thermoplastics with break-away and dissolvable support structures

Layer resolution

200-250 microns

Platform levelling

Automatic measurement of platform points height

Minimal wall thickness

450 microns

Maximum printing temperature (extruder)

480 °C (896 °F)

Maximum platform temperature

220 °C (428 °F)

Maximum build chamber temperature

200 °C (392 °F)

Ambient operation temperature

17-30 °C (63 - 86 °F)

Storage temperature

0-35 °C (32 - 95 °F)