By eliminating the need for us to manually machine or otherwise create pieces, the Fuse 1 saves us time and resources. Instead of taking weeks, we can complete the design to print process quickly. While the Fuse 1 handles many of the less functional jobs that our company is required to complete, the extra time can be used to work on new product development and more important, complicated projects. When we can, we use it every day.

Superior Print Speeds

Thanks to a potent 30W laser that prints at scan speeds of up to 12.5 metres per second, high-precision items can be delivered within 24 hours.

Industrial Grade Materials

With active powder handling and an inert gas print option, you may access exclusive new materials and improve performance on already-existing ones.

Zero Waste, High ROI

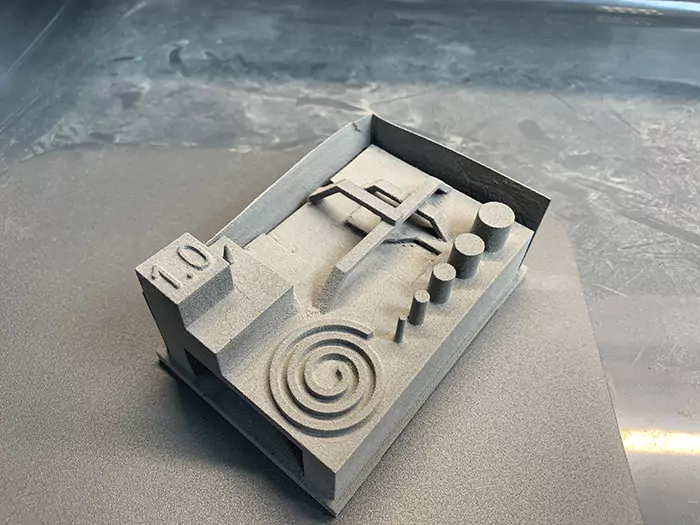

We've achieved a significant milestone, zero waste Printing by maximizing packing density and powder recyclability, which lowers the cost per part.

Control internal manufacturing and prototyping as needed. The Fuse 1 has a tiny size, industrial power, good powder containment, and is simple to set up.

A full colour touchscreen interface that is designed for low maintenance walks customers through each Printing and maintenance step.

The Fuse 1 makes industrial-quality SLS Printing accessible to everyone thanks to its low price, economical materials, and quick material refresh rate.

Use up to 70% recycled powder for Printing.

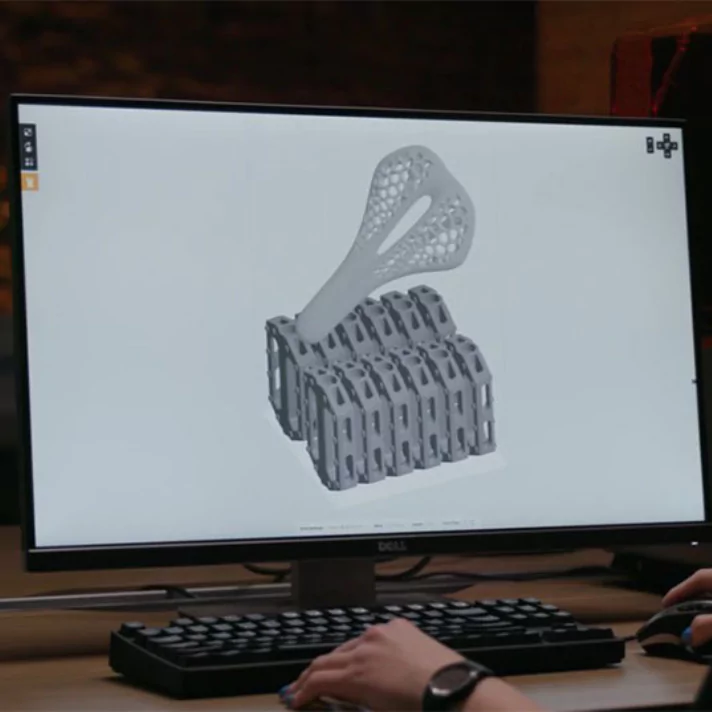

The Formlabs PreForm print preparation software (free to use) imports STL or OBJ part files and makes it simple for users to position models, gauge print times, upload job files, and keep track of Printer usage.

The PreForm software automatically recommends the best part packaging and orientation.

Using the touchscreen of the Printer or a computer, watch a live video feed of your print in progress.

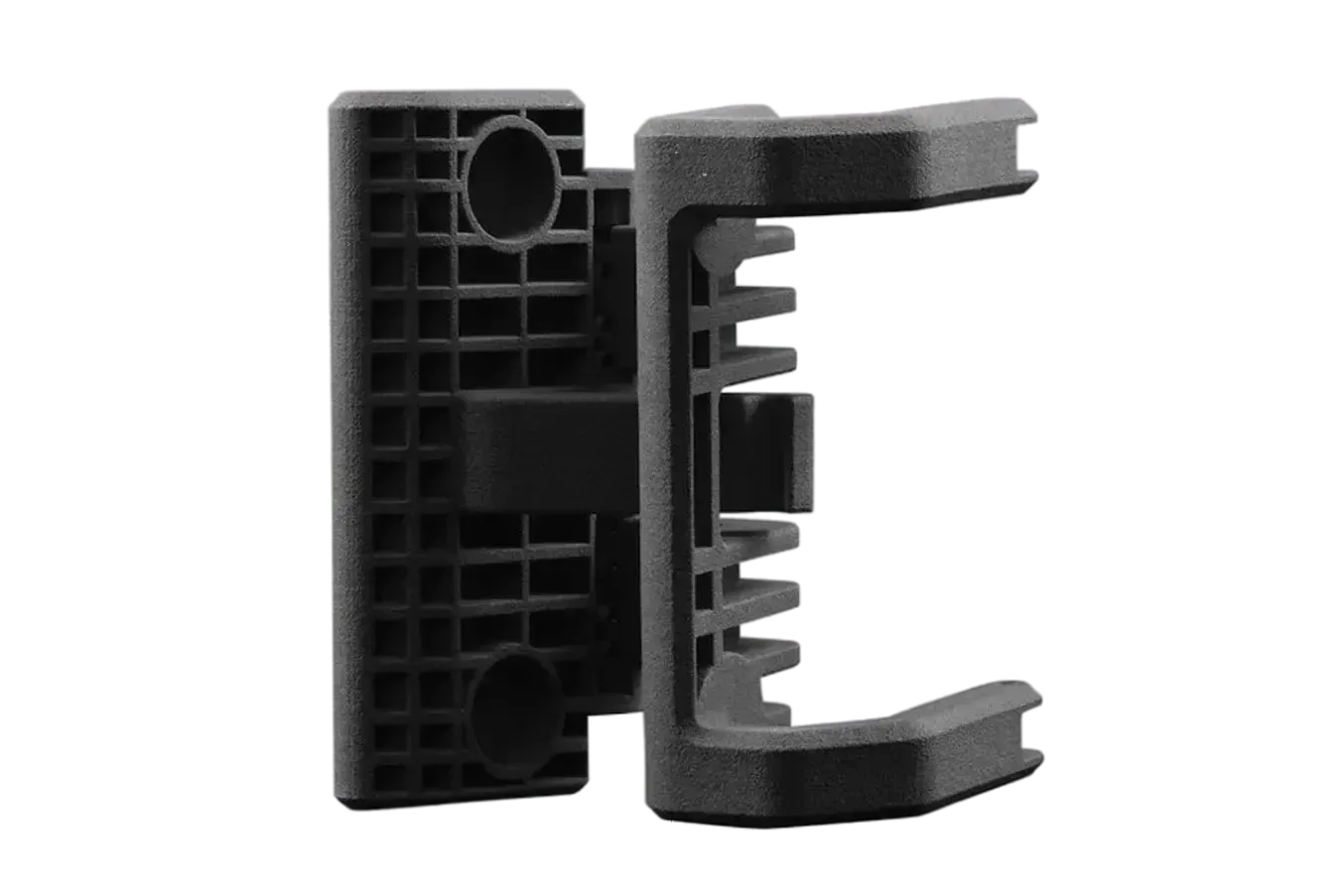

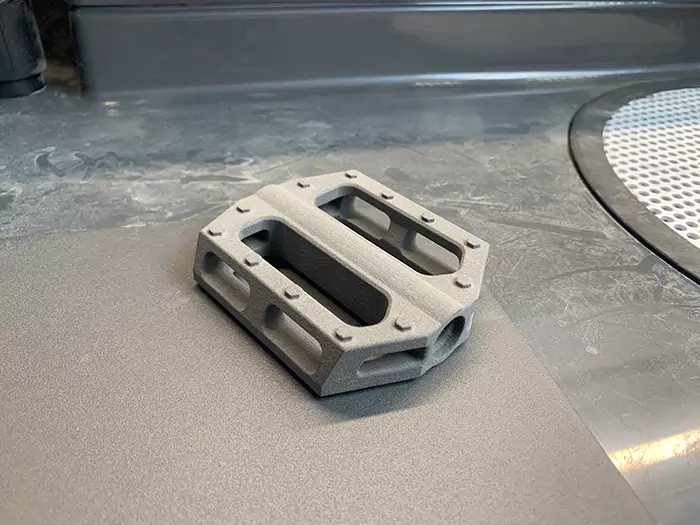

The Fuse 1 offers competitive mechanical characteristics and surface finish thanks to patent-pending Surface Armor technology without the high price or inconvenience of competing systems.

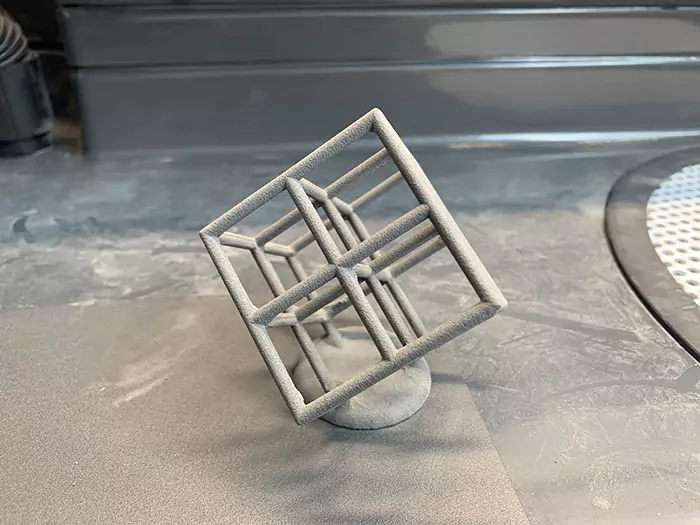

When creating prototypes and small batches of finished pieces while iterating on ideas, use the same procedure and material.

As many parts as you can put in the construction chamber to reduce post-processing time.

To provide constant part quality and mechanical qualities, the Fuse 1 forms a semi-sintered shell over the surface of the component.

A secure and effective powder recovery mechanism for the Fuse 1 is the Fuse Sift. Part extraction, powder recovery, storage, and mixing are all included in this single free-standing unit.

The PreForm software automatically recommends the best part packaging and orientation.

Using the touchscreen of the printer or a computer, watch a live video feed of your print in progress.

When creating prototypes and small batches of finished pieces while iterating on ideas, use the same procedure and material.

As many parts as you can put in the construction chamber to reduce post-processing time.

To provide constant part quality and mechanical qualities, the Fuse 1 forms a semi-sintered shell over the surface of the component.

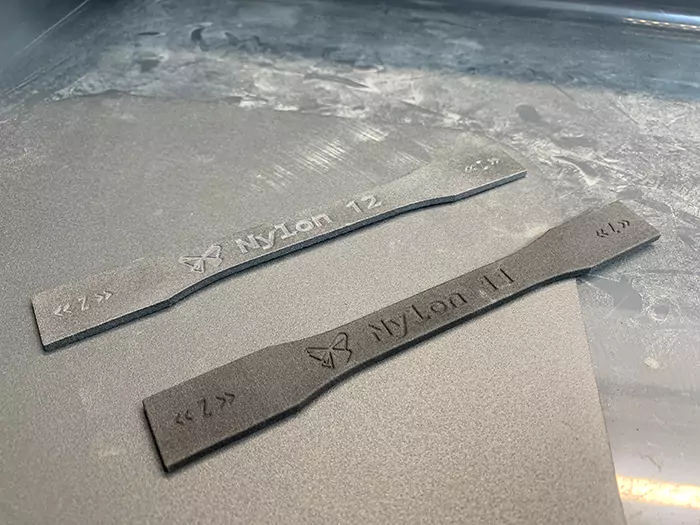

The Fuse 1's capacity to print robust, usable nylon parts is what gives it its true power. Nylon 12 Powder is a very capable material for both functional prototype and end-use production of complicated assemblies and durable parts with great environmental stability. It balances strength, flexibility, and intricacy. Our Nylon 12 Powder was created especially for use with the Fuse 1.

Nylon 12 Powder is ideal for:

Control the entire product development process, from creating iterations of your initial concept design to producing finished goods:

Own your supply chain and act rapidly in the face of shifting consumer needs:

Manufacture ready-to-use, patient-specific medical devices in-house:

Technology

Selective Laser Sintering

Build Volume

165 × 165 × 300 mm (W x D x H)

Layer Thickness

110 microns

Laser Type

Ytterbium Fiber 10W

Laser Spot Size (FWHM)

200 microns

Build Chamber

Modular, compatible with Fuse 1 generation Printers and Fuse Sift

Hopper Capacity

17.8 Liters

Printing Dimensions

68.5 x 64.5 x 106.5 cm

Stand Dimensions

59.6 x 60 x 58.4 cm (W × D × H)

Weight

114 kg (without build chamber or powder)

Startup Time

< 60 minutes

Operating Environment

18 – 28 ºC

Internal Temperature

Up to 200 ºC

Temperature Control

Quartz tube heating elements Positive temperature coefficient (PTC) cartridges

Air Handling

Pressure-controlled two-stage filtration

Power Requirements

EU: 230 VAC, 7.5 A (dedicated circuit)

Galvanometers

Formlabs Custom

Laser Specifications

Ytterbium Fiber IEC 60825-1: 2014 certified 1070 nm wavelength Maximum 10 Watts 4.01 mrad beam divergence (nominal, full angle)

Laser Spot Size (FWHM)

200 microns

Radiation Information

The Fuse 1 is a Class 1 Laser product. Accessible radiation is within Class 1 limits.

Connectivity

Wi-Fi (2.4GHz + 5GHz) Ethernet (1000 Mbit) USB 2.0

Printer Control

10.1” interactive touchscreen 1280 × 800 resolution

Alerts

Touchscreen alerts and tracking SMS/email via Dashboard Live video feed with computer vision Proactive maintenance alerts

Print Preparation

PreForm Desktop Software

System Requirements

Windows 7 (64-bit) and up Mac OS X 10.12 and up OpenGL 2.1 4 GB RAM (8 GB recommended)

Hardware Requirements

Fuse 1 generation 3D Printer

File Types

.STL or .OBJ FORM file output