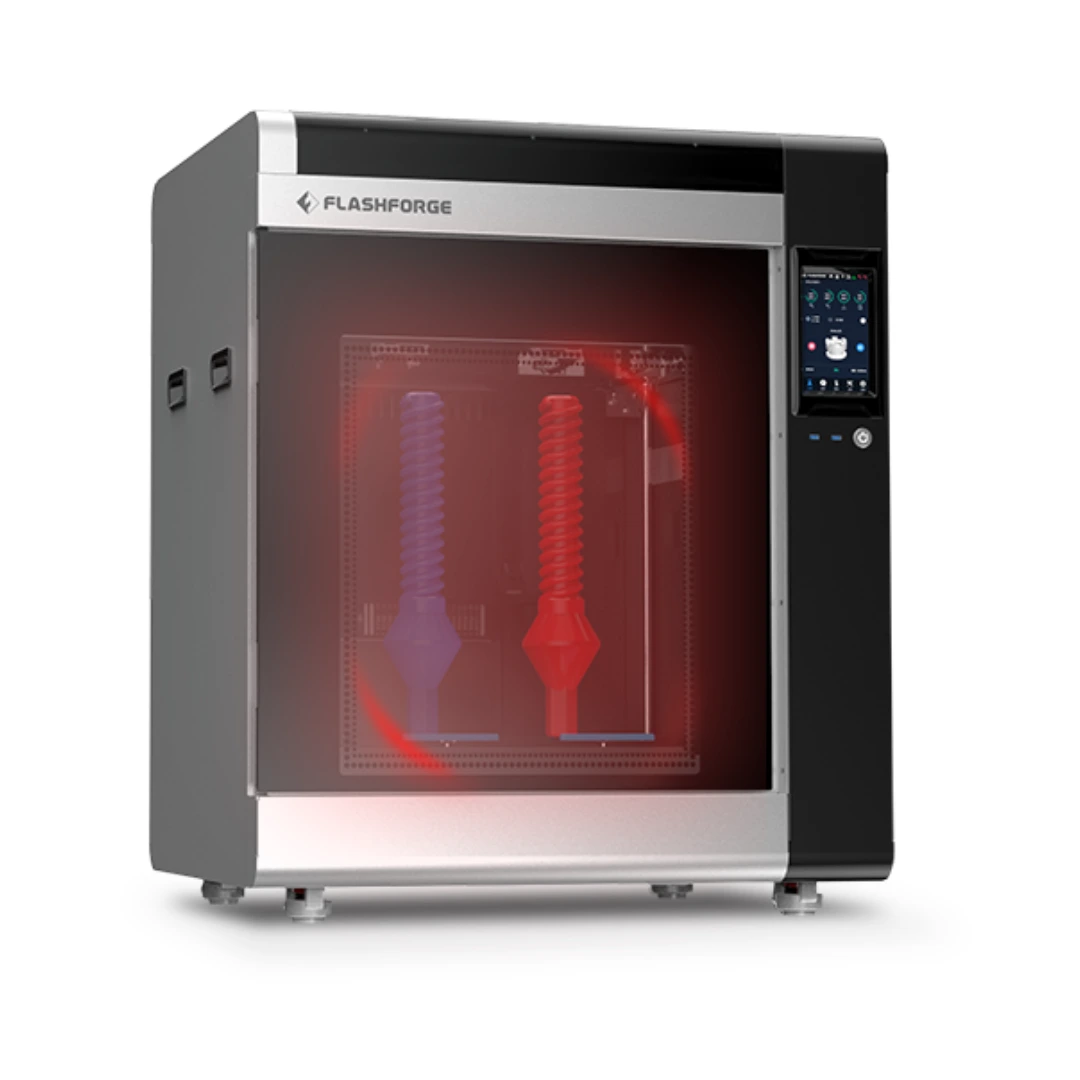

Flashforge Creator 4

A powerful 3D Printer for Business

A powerful 3D Printer for Business

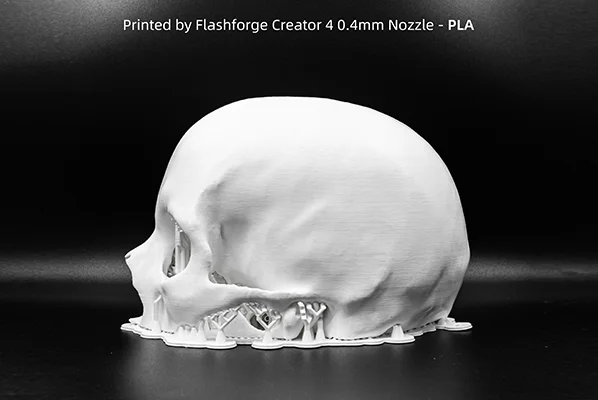

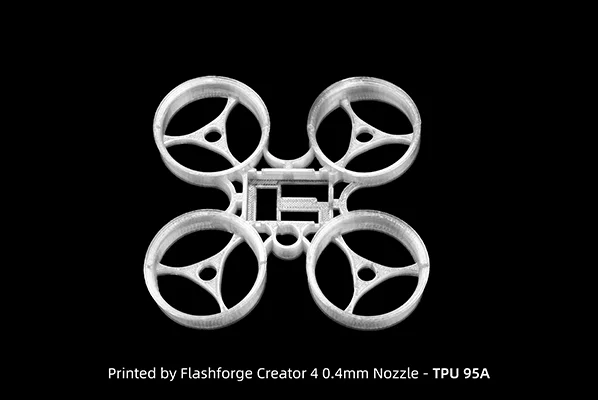

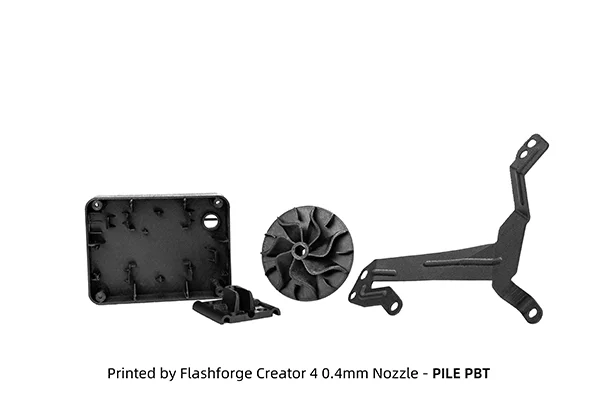

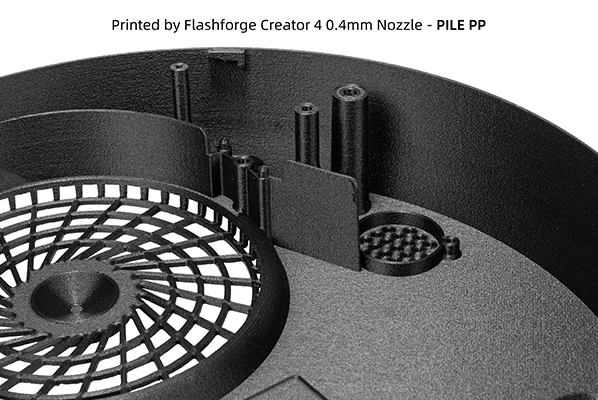

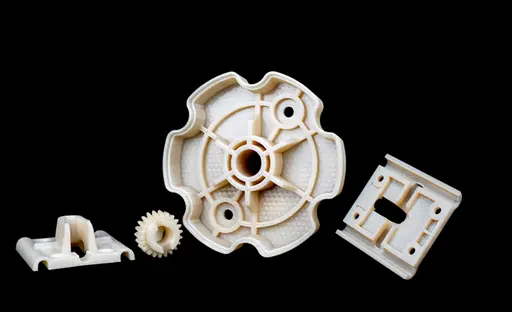

A powerful 3D Printer for business use is the Flashforge Creator 4. A strong alternative for commercial manufacturing, the Creator 4 3D Printer has three extruder options that allow it to Print with flexible filaments, engineering filaments, and carbon fiber composite filaments.

HEPA 13 air filter

7-inch smart touch screen

Built-in-camera with remote control

Printing resuming after recovering from power failure

Built-in-filament 2kg + 1kg

Auto power-off

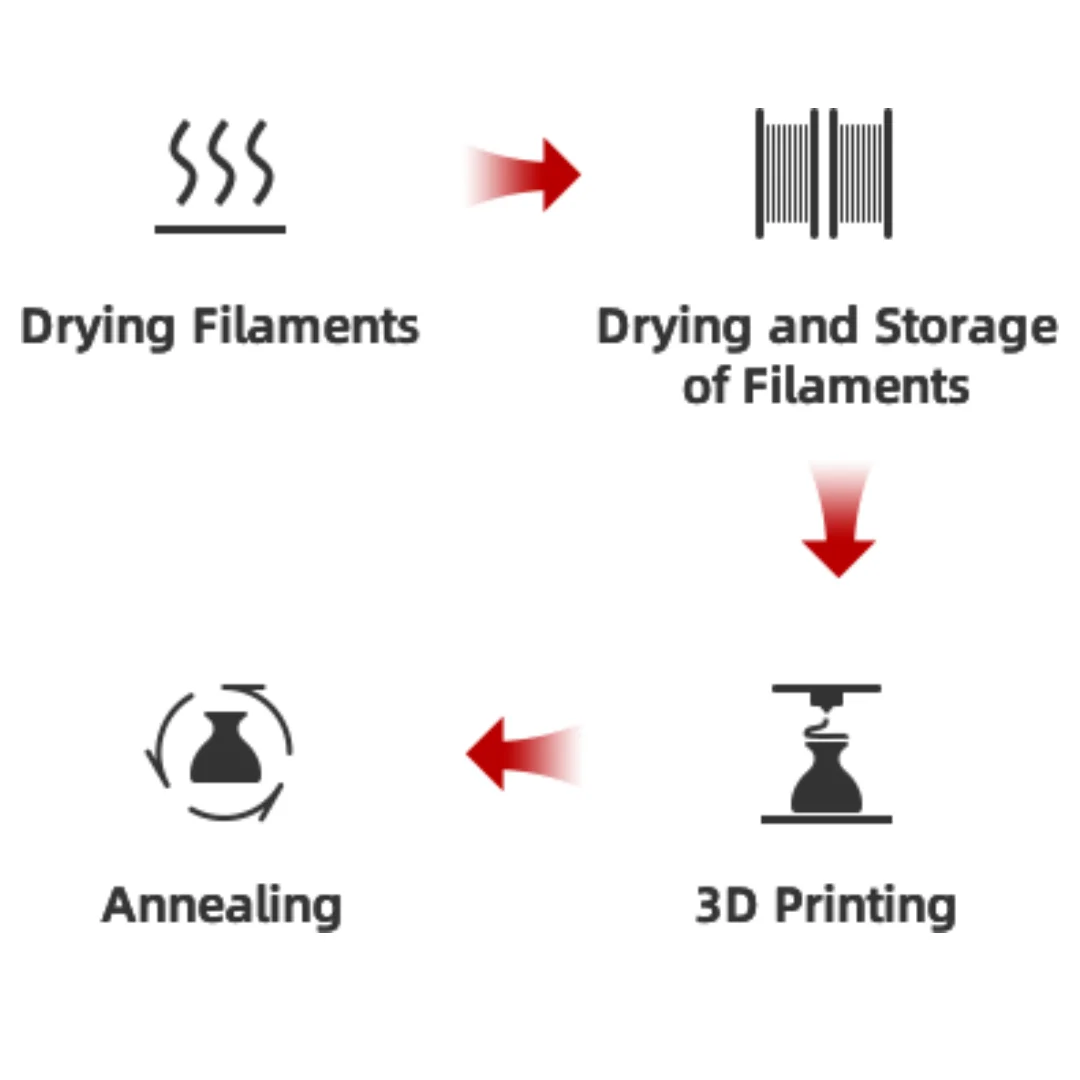

The Filament Drying Station is a multipurpose item that combines the ability to move the shelves around, store and dry 3D Printing filaments, and position 3D Printing equipment. It intends to solve the issue of filament drying and storage as a complementary product to Creator 4 and restore the qualities of wet filaments

It can be used as a raised shelf because its size is the same as that of the Creator 4. Its casters make it easy to move and switch the working area as needed.

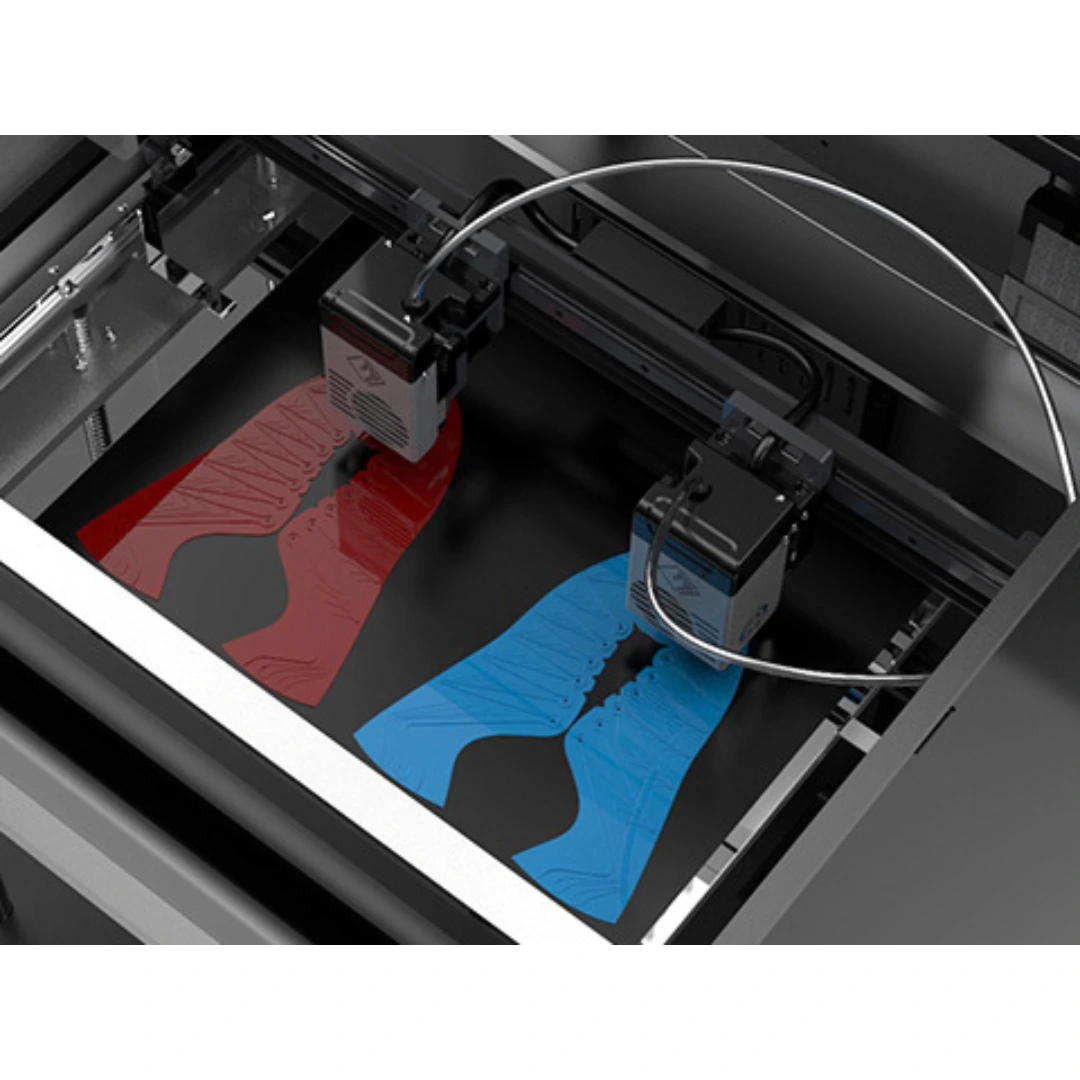

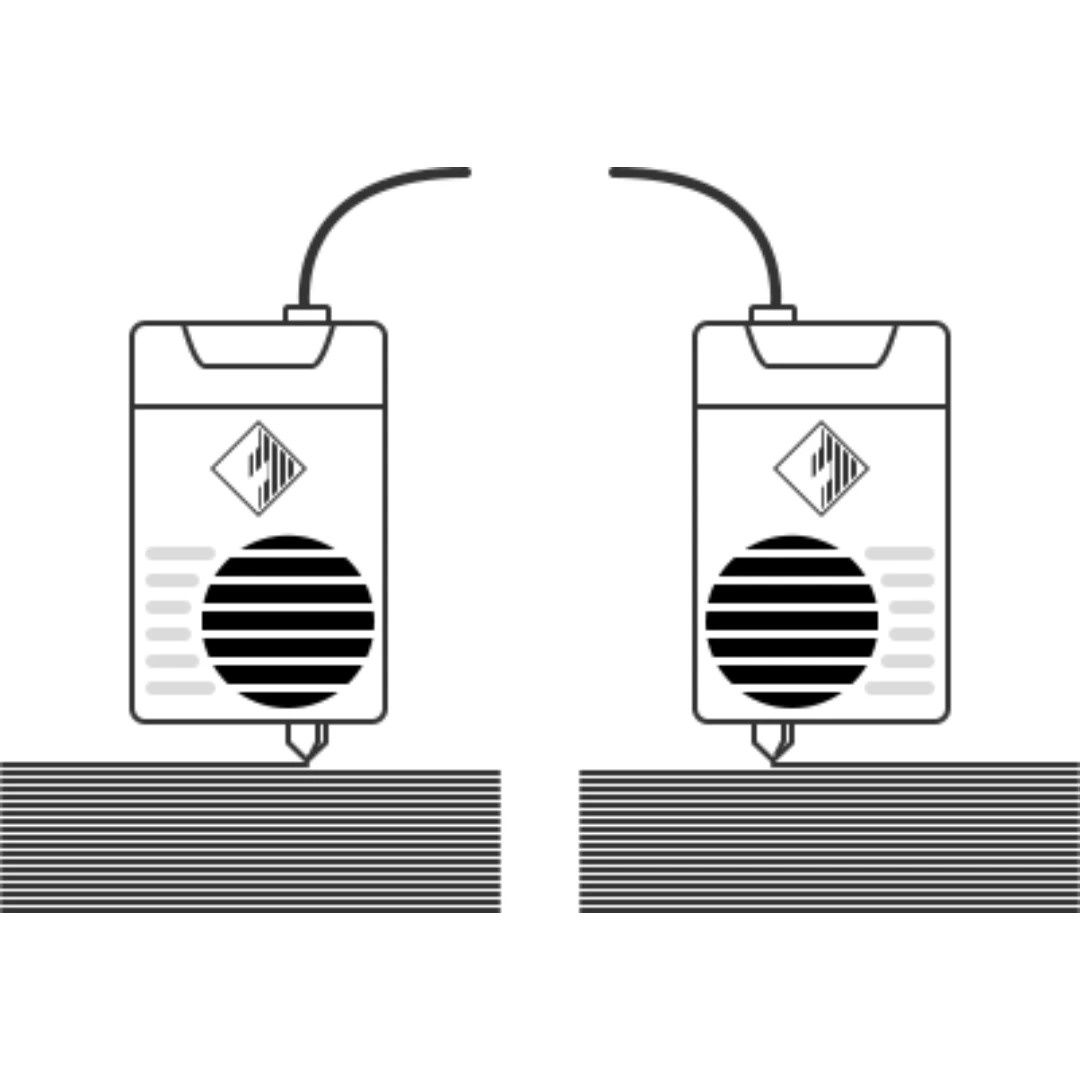

In Creator 4, the two extruders operate separately and are not connected to one another. This prevents filament from being overflowed onto the Printed object when one extruder is selected to work while the other moves away from the Printing area. Additionally, you may quadruple your outputs by using two separate and concurrent extruders. A decent option for mass production is Creator 4.

Creator 4's cutting-edge thermal-control system maintains the Print chamber at 65°C, thus reducing model shrinkage, corner warping, and supply breaking. Creator 4 significantly increases the Print success rate while ensuring good Printout quality and Printing precision.

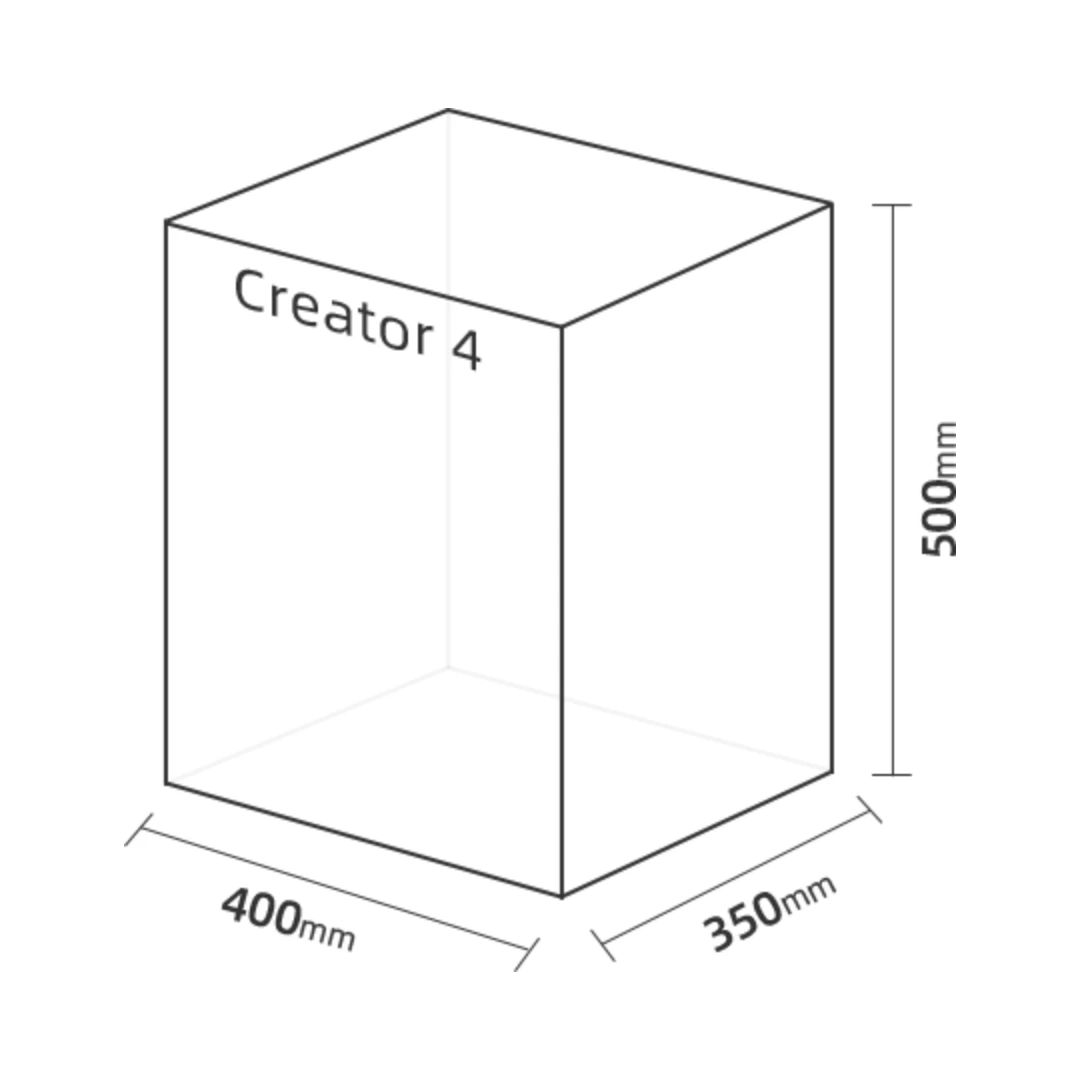

The majority of manufacturers can Print at the Printing size of 400 mm x 350 mm x 500 mm.

Motion stability is considerably increased by linear-rail leadscrew stepping along the X and Y axes, which contributes to higher Printing accuracy.

The nozzle is positioned precisely, the start and stop motions are smoother, and the Printing details are fantastic thanks to the brand-new S-type motion control technology.

When a machine is working, its CNC construction keeps it stable and reduces shaking.

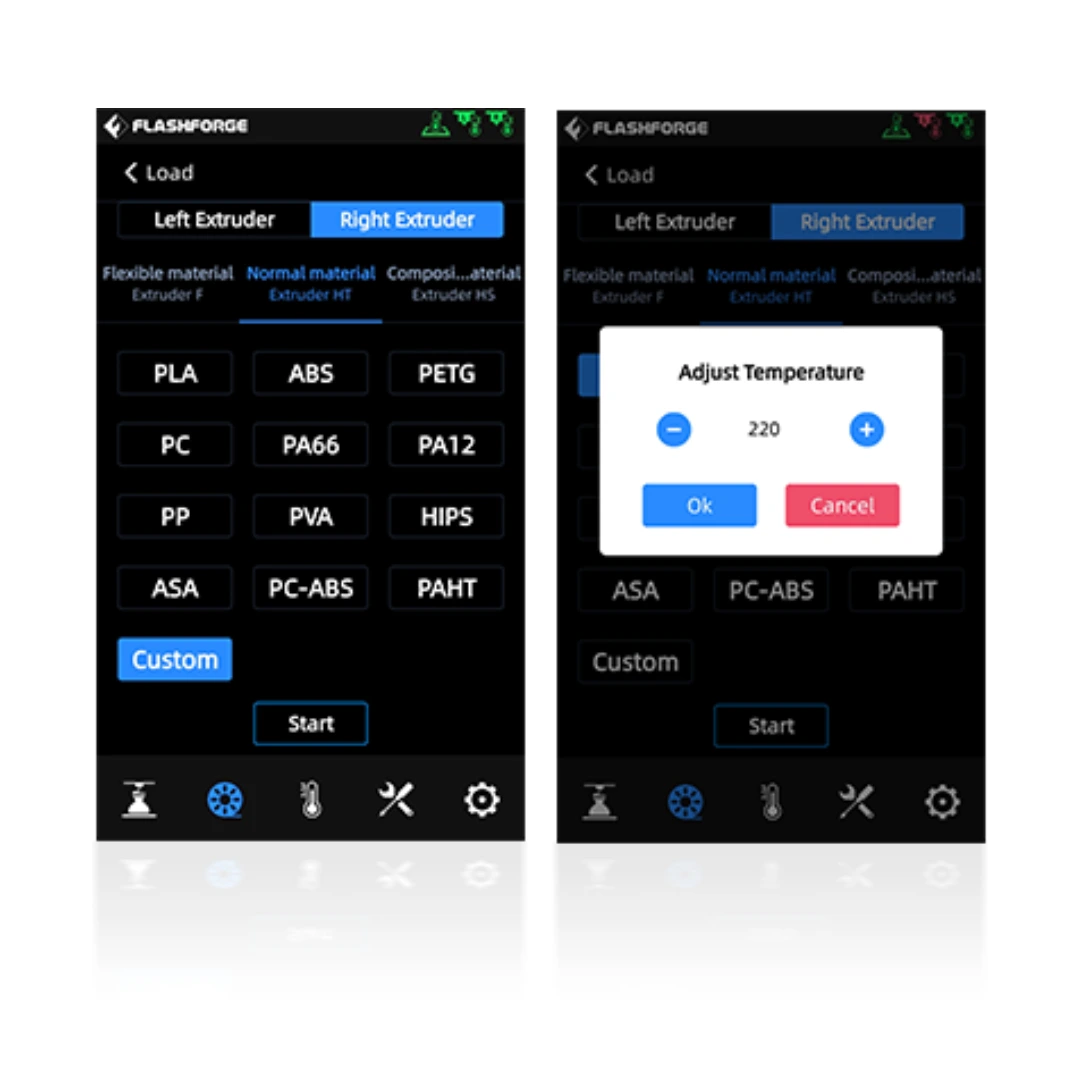

A higher success rate of Printing can be achieved by automatically adjusting different filaments to various preheating temperatures in the chamber. The chamber temperature can be automatically adjusted once Printing is complete to allow models to cool. For the following Print, the system is quite user-friendly. You can alter the temperature if you don't want it to be set automatically.

The Filament Drying Station optimizes the entire 3D Printing process, maintains stable filament usage throughout the entire workflow, maximizes the typical operating time of your Printer, and ensures Printing quality.

Extruder-F for flexible filament.

Extruder-HT for engineering filament.

Extruder-HS for carbon fiber composite.

( Printing for 85A Flexible Filament )

Printing Speed

100mm/s

Filament Diameter

2.85mm

Printing Temperature

265℃

Supported Filament

TPU85A / TPE /

TPB / TPC

Extruder type

IDEX

Nozzle diameter

0.4mm

Maximum chamber heating temperature

65℃

Printing volume

400*350*500mm

Maximum platform heating temperature

130℃

Touch screen size

7-inch

( Printing for Engineering Filament )

Printing Speed

200mm/s

Filament Diameter

1.75mm

Printing Temperature

320℃

Supported Filament

PC / PA / PP / PETG / ASA / ABS / PLA / PC-ABS / PAHT

Extruder type

IDEX

Nozzle diameter

0.4(0.6/0.8)mm

Maximum chamber heating temperature

65℃

Printing volume

400*350*500mm

Maximum platform heating temperature

130℃

Touch screen size

7-inch

( Printing for Carbon Fiber Composite )

Printing Speed

150mm/s

Filament Diameter

1.75mm

Printing Temperature

360℃

Supported Filament

PACF / PET-CF / PP-CF / PA-GF / PC-ABS / PP-GF / PPS-CF / PPS

Extruder type

IDEX

Nozzle diameter

0.4(0.6/0.8)mm

Maximum chamber heating temperature

65℃

Printing volume

400*350*500mm

Maximum platform heating temperature

130℃

Touch screen size

7-inch

Custom Printing of production equipment wear parts, jigs & fixtures, and tooling is one example.

Capable of Printing the design immediately to check the product's functionality.

Capable of Printing mall-batch part production.