|

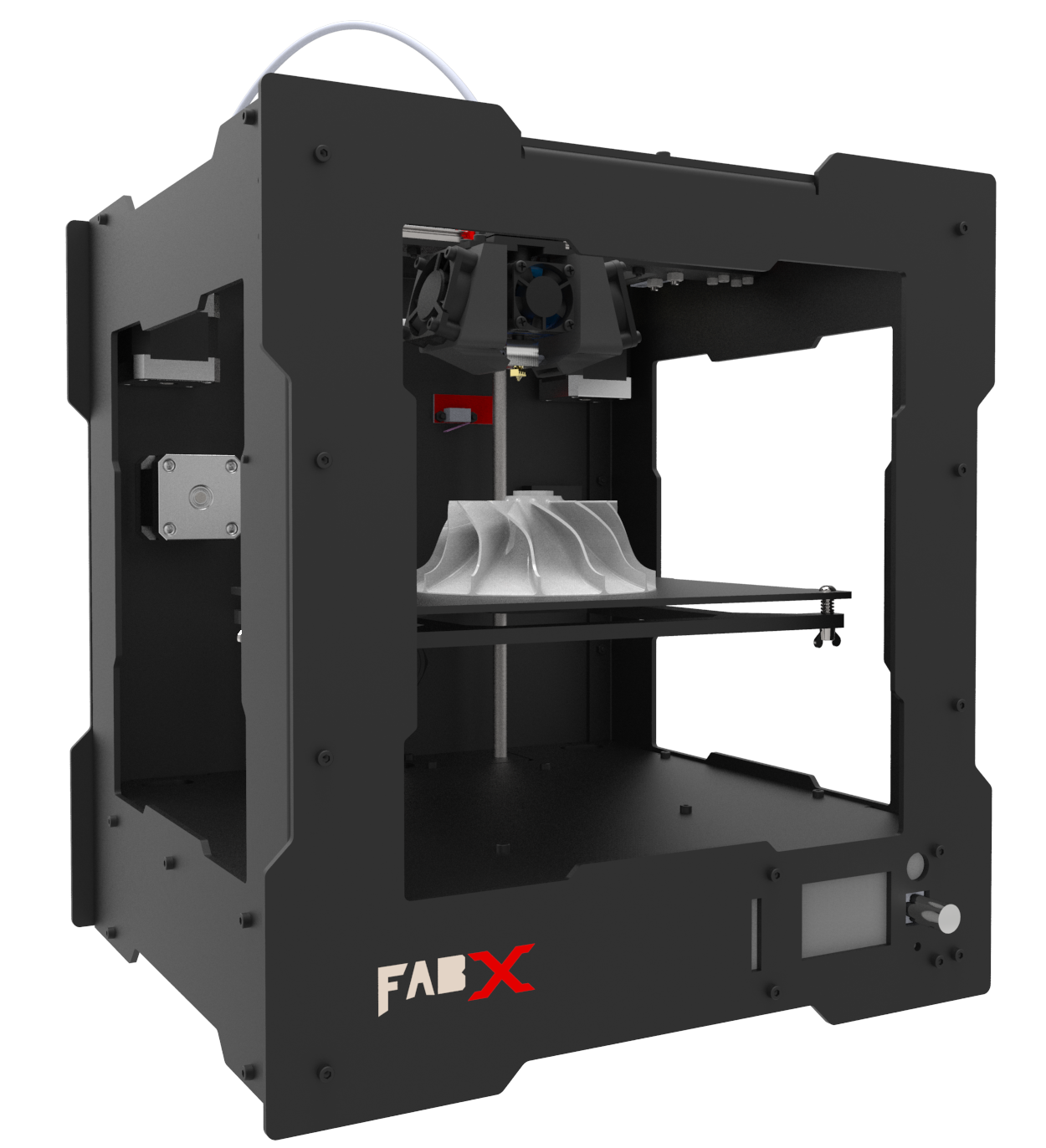

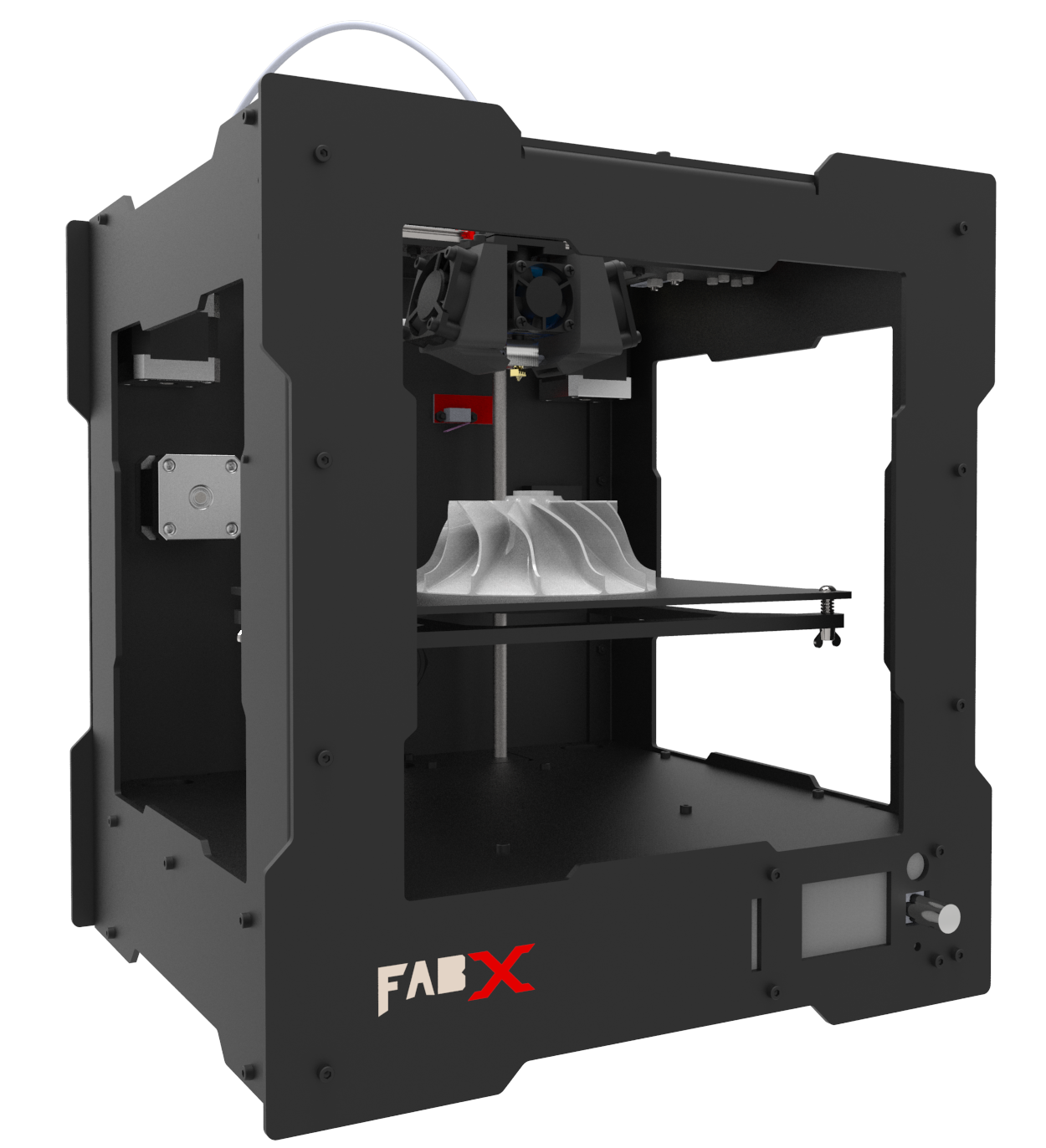

3D Print, Like a Pro..Professional Quality 3D Printing

|

|

3D Print, Like a Pro..Professional Quality 3D Printing

|

|

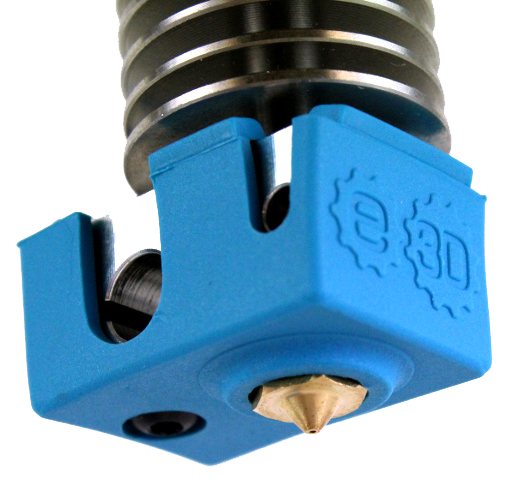

One of the unique features of the FabX Pro is theE3D v6 hotendWhile most 3D Printers reach a maximum of 250° C, the FabX Pro can go upto 300° C, making it compatible with advanced materials like ABS, Nylon, Carbon Fiber etc. |

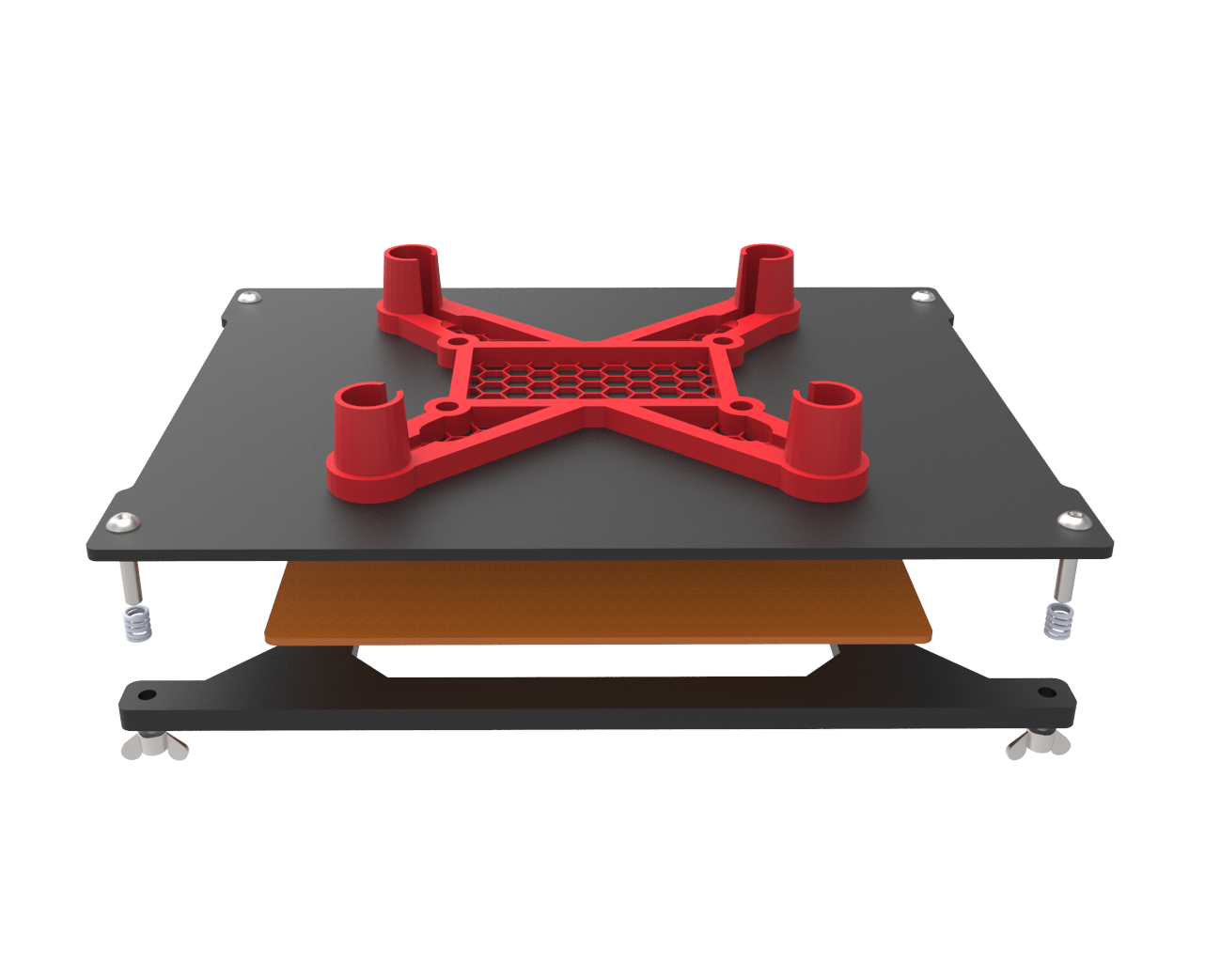

Heated BedThe heated bed distinguishes the FabX Pro from all other 3D Printers in it's category.

|

|

|

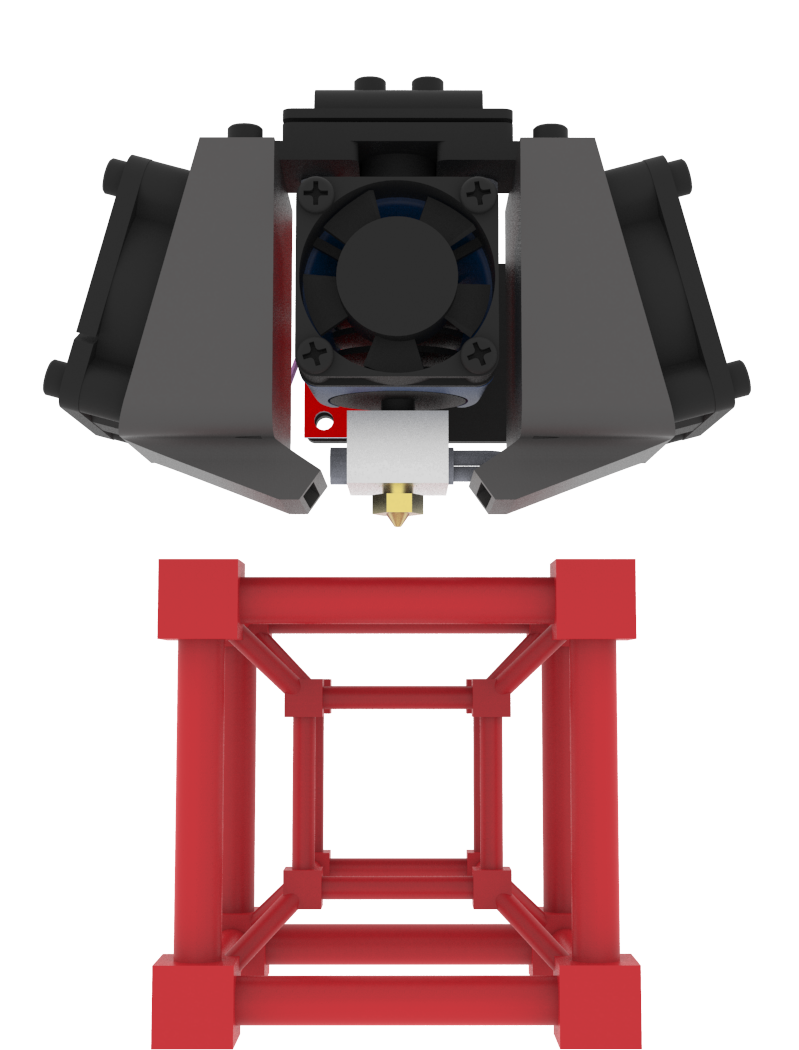

The FabX Pro packs an E3D Hotend moving on premium Industry-Grade rails.

|

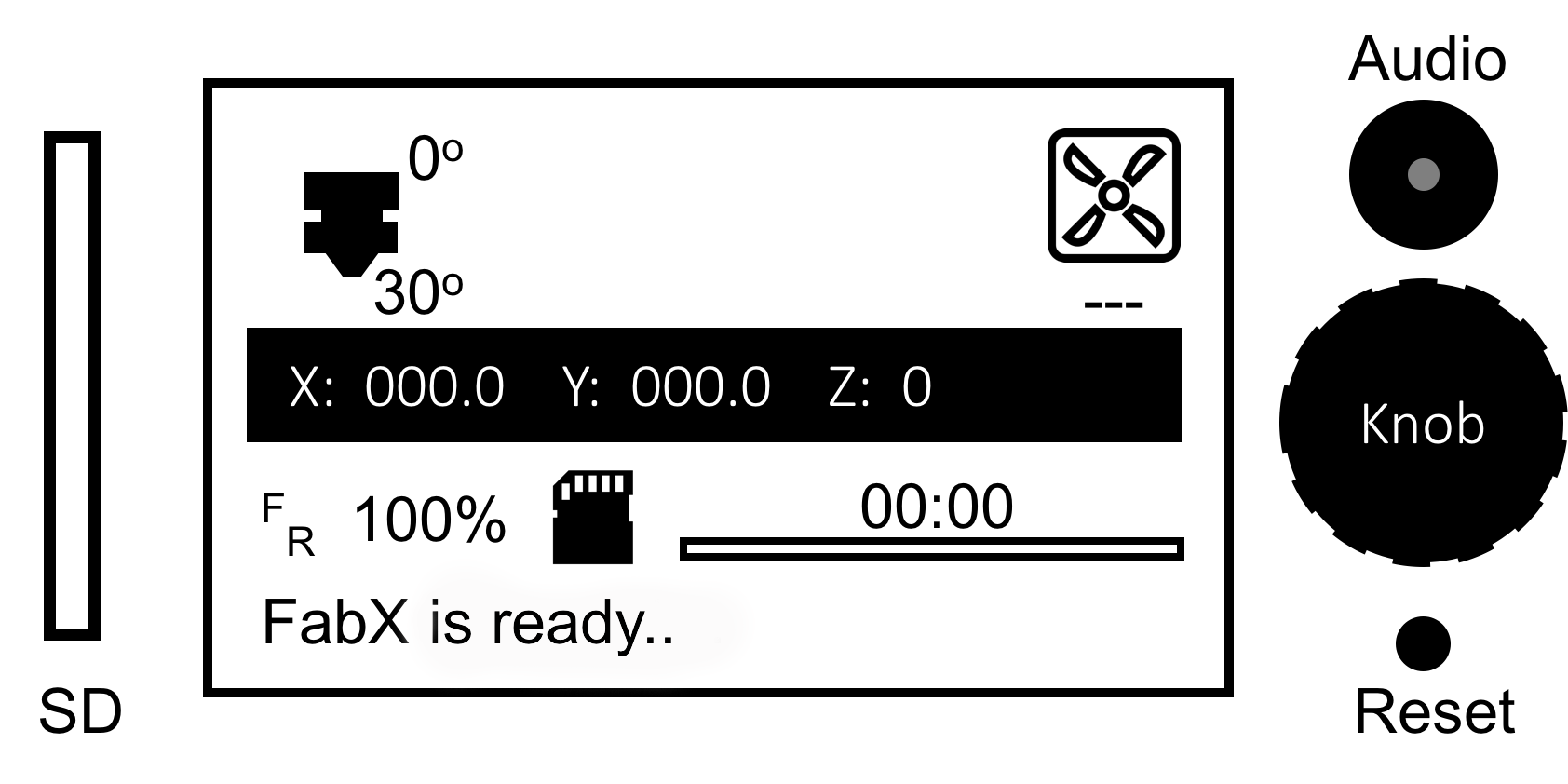

Sleek Control Panel |

|

|

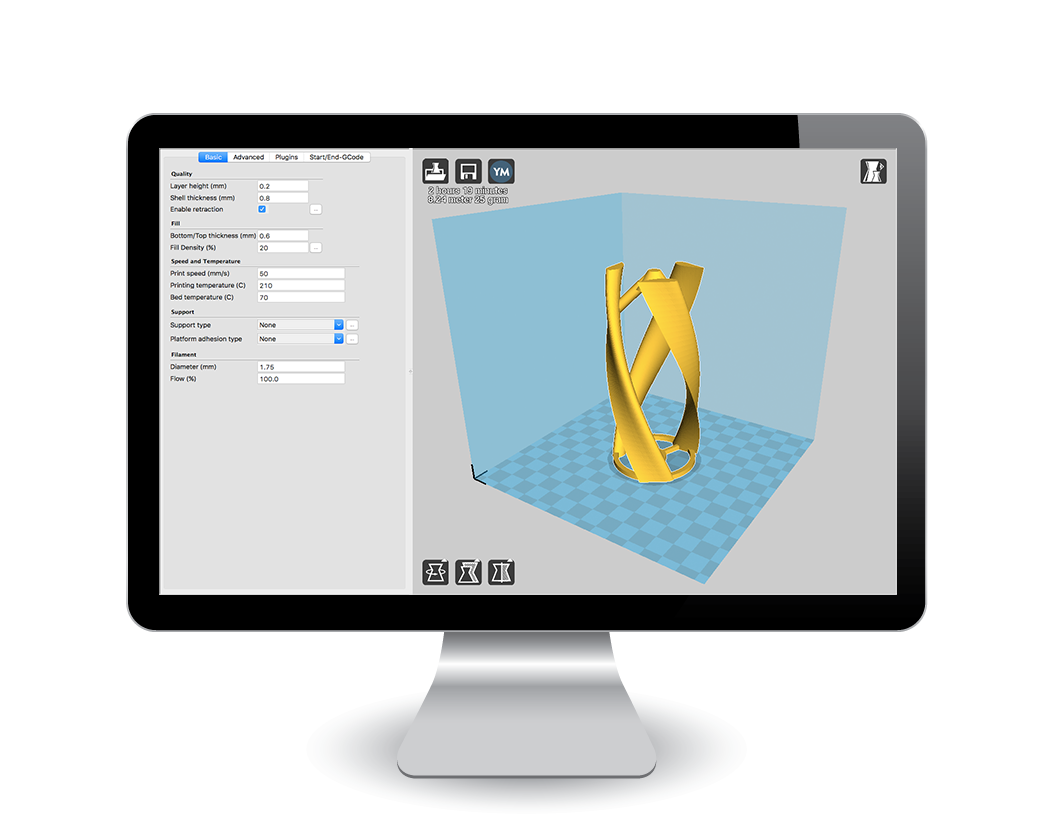

Import from your favorite Design PlatformTinkercad, Sketchup, Solidworks, Fusion360, Maya, Zbrush, Openscad or any of the various CAD software, Export in one of the compatible formats like stl, obj, amf, etc & you’re ready to 3D Print.Slicing SoftwareThe FabX Pro runs Marlin, meaning which it’s compatible with a variety of Slicing Software.Cura, Simplify3D, Mattercontrol, Slic3r, the list goes on..RecommendedBeginners : Cura (Free)

|

FFF (Fused Filament Fabrication)

Yes (Upto 110° C)

150 L X 150 W X 150 H mm

5.91 X 5.91 X 5.91 in

50~300 microns

XY: 11 microns [0.0004 in]

Z: 2.5 microns [0.0001 in]

1.75 mm [0.069 in]

0.4 mm [0.015 in]

175 to 300 Degrees Celcius

Aluminium

One

326 X 306 X 354mm

TBA

10KG

15KG

Cura, Simplify 3D

STL, OBJ

Windows 7/8/10

Mac OS X

USB Cable, SD Card, LCD

English

~230 V, 50-60 Hz

60W-Without Heated Bed

150W-With Heated Bed

In the box..

Filament not included in the box |

|