Nowadays, architects and interior designers are facing more challenges like demanding turnaround times, personalizations, customizations and growing competition.

But top architects and interior designers are turning these challenges into opportunities by giving themselves a competitive advantage — 3D Printing.

With 3D Printing, architecture and interior design firms have gained significant productivity boost generating immense value to them.

1. Reinventing Model Making Process

Not only is model making time consuming, but it’s also a chaotic, complex and labor-intensive process. But model making is a very important step that can be seldom overlooked.

With traditional methods, it takes forever to create one physical model using foam, timber, glue which is prone to human errors. The models cannot be edited or replicated with the exact accuracy and quality again. If the model gets damaged, you have to start from scratch and undergo a laborious process.

With 3D Printing, architects can just 3D Print their models with zero/negligible work from their side. 90% of the process is taken over by the 3D Printers.

Clients also expect physical models to visualize their plans effectively and firms have to showcase physical models for potential leads to seal the deal. The faster you do it, the better your chances for success.

Automating a large amount of this process has helped firms reinvent their entire model making lifecycle faster and better.

2. Complimenting the ecosystem

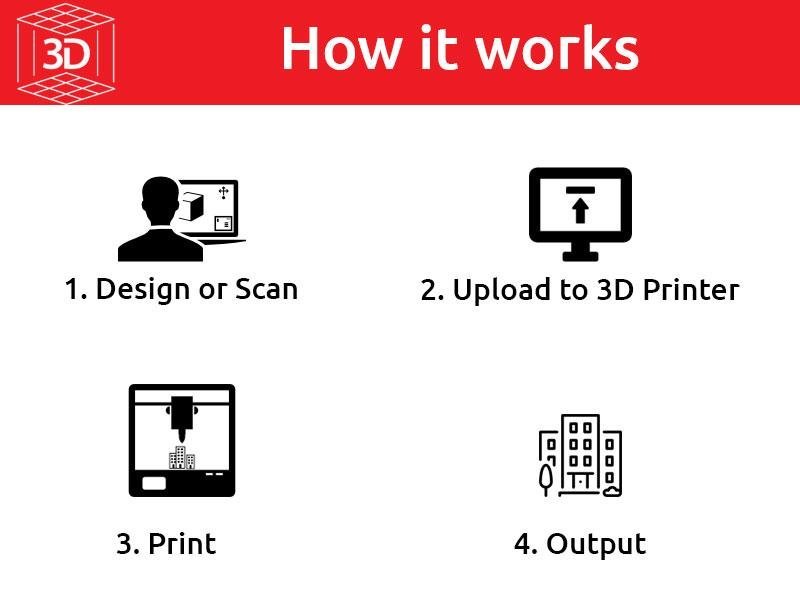

One major advantage to 3D Printing is its ability to bridge the digital and physical process of creating a model.

Every architect and designer knows the painful process they go through to get a blueprint or design to be realized as a physical model. Especially with traditional model making which is prone to errors w.r.t aspect ratios and intricate details.

Since 3D Printers completely relies on the digital design to create the model, architects and designers can seamlessly integrate their CAD applications directly with the 3D Printing process without any hassle. This enables to create highly accurate scale models without leaving out the intricacies.

Now designers and architects can share their design files halfway across the world and get it 3D Printed the same way at the same time with the same accuracy at negligible/no labor costs.

3. Increased Productivity:

With firms owning a 3D Printer, rapid prototyping has become a reality. This helps designers to iterate their designs faster than ever before. With accurate models portraying their vision, efficient solutions are achieved at even shorter turnaround times.

This has also increased the flexibility and productivity for architects to realize their designs faster, make changes if necessary and arrive at the final design.

4. Return on Investment:

Since 3D Printing is user-friendly and cost-effective, firms are getting good ROI on their investments with negligible recurring expenses.

Another major advantage of a 3D Printer is its independent of human interaction or interruptions while printing.

With the advent of Cloud 3D Printing, users are not even expected to be around the machine to start a print. All one has to do is give the command from their mobile or laptop and within a few hours, the models will be ready.

This has cut down huge labor costs for the firms, improving their outputs while significantly cutting down on the disadvantages of current processes.

5. Personalization

With growing popularity and demand for personalization and customization in every project. 3D Printing enables architects and especially interior designers to drive their efforts with more creative freedom.

Since the technology is based on additive manufacturing, a lot of complex designs which were impossible to be manufactured are now possible using 3D Printing.

Moreover, 3D Printing is ideal for low batch production and mass customization enabling designers to play around with more creative freedom. This has significantly reduced the capital and time involved to create personalized designs, prototypes, and products.

With many companies in India still using conventional methods or some using 3D Printing Services, the potential of 3D Printing is yet to be realised in the Indian Architectural space. With 3D Printers like FabX XL – an easy to use 3D Printer custom made for Architects and Interior designers, firms can now invest in a 3D Printer which is affordable and powerful for their end goals.

How could I learn 3D printing

Hi Sagar, there are plenty of online resources and courses to get started. But if you want a more hands on experience, 3Ding conducts One Day 3D Printing workshops for beginners across many cities in India. Know more about this at 3ding.in/workshop

Great post! Thanks for sharing this useful information about 3D Printing.

hello sir,

your post does much clears about 3d printing or I am not able to learn better through your post so, can you plz described more for better understanding. And after reading this post visited another site binashree which also provides 3d printing services and their post are really well to understand.

Thank you for the guidance..

I agree with your post that really beneficial for the architect and the 3D model will give provide the idea of architecture before it, constructor. Your article is a very delightful and advanced technology. It is remarkable indeed.

I am Architecture that’s why I know how helpful the 3D printers for making the exact demo version of a big project structure in a small-time. It is very effective for the client how is interested in this project and understand it better way.

Thank you for the guidance.. It does work.

Thanks for sharing valuable information with us. It really helped me understand the process.

The probability of making money through 3D printing technology is increasing day by day. The technologically advanced country nowadays use the 3D printing technology to build house, road etc. that’s why we can say that day by day the 3D printing industry increasing rapidly. In the 3D printing technology, it needs less manpower and less money. Tha’s why most of the leading company nowadays use 3D printing technology.

You’re right. Architects & Interior designers must use 3D printing. Especially when we keep ROI in mind, it’s a major advantage.