Snapmaker Artisan 3-in-1 3D Printer

Incl. of all taxes • Free shipping

Snapmaker Artisan 3-in-1 3D Printer

₹3,39,999

₹3,39,999

Snapmaker Artisan 3-in-1 3D Printer

3-in-1 Printing | Laser Engraving | CNC Carving

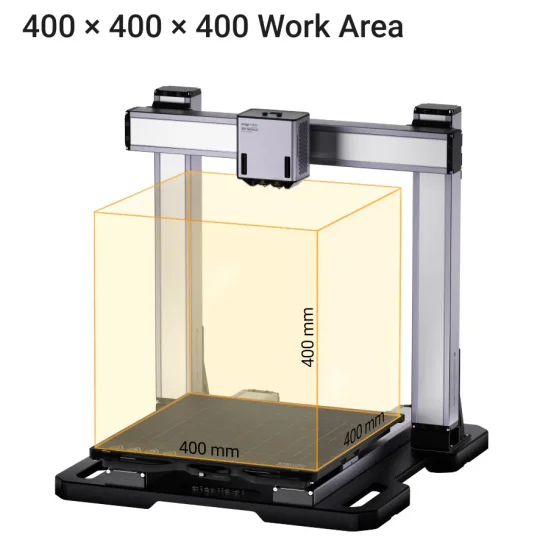

Looking for a versatile 3D Printer that can handle a wide range of projects? The Snapmaker Artisan 3-in-1 3D Printer outperforms Snapmaker 2.0 in terms of printing speed, accuracy, filament compatibility, and accessibility. With precision printing, laser engraving (10W), and CNC carving (200W) capabilities, this machine is perfect for makers, artists, and hobbyists. Its user-friendly Luban software and sturdy industrial-grade construction make it a great choice for beginners and experts alike. Featuring a massive 400×400×400mm work area, 180 mm/s high-speed printing with 0.1mm dimensional accuracy, 7" ultra-wide touchscreen, and zone-heated bed technology.

Features Of Snapmaker Artisan 3-in-1

Industrial-grade Transmission Technology

Steel guiderails that are embedded in Artisan's linear modules were produced by CNC grinding at the micron level, bringing desktop fabrication up to industrial-grade transmission standards. As a result, accuracy, rigidity, and durability are significantly increased, giving you a quick, precise, and steady making experience.

Never Let Space Restrictions Prevent You From Exploring Your Ideas

In a large work area measuring 400 mm x 400 mm x 400 mm, create large or numerous objects as you desire. Quick-swap platforms and toolheads enable you to switch between three tasks in under a minute.

All-metal - Up Level

The Artisan features an improved one-piece die-cast base plate that is larger in addition to getting Snapmaker's distinctive all-metal design. Even during high-speed CNC cutting, it maintains a rock-solid stability.

7" Ultra-wide Touchscreen For More Play Space

Broaden your vision. Workflow is more fluid. More user-friendly interface design. And an operation that is more ergonomic.

Snapmaker Luban - All-in-One CAM Solution

Snapmaker Luban, a custom-made program, provides a brief and simple configuration procedure for 3D printing, laser and CNC machining. Excel in three fabrication procedures with just one piece of software. The latest Luban includes more practical printing modes.

Dual Extrusion 3D Printing Module

Rapid swapping of hot ends is possible for toolheads and platforms. Luban recognises the nozzle sizes and types and provides you tailored configurations. A motor is included to automatically lift and switch between two extruders without additional toolhead movement, making dual-extrusion 3D printing faster and quieter.

Printing on Dissolvable Supports

Artisan includes a Dual-extrusion 3D Printing Module that works with PVA, HIPS, and other soluble materials. Just soak the print to dissolve the supports, leaving the model with smooth surface finishes. The complexity of geometry is no longer an issue.

Save Time with Zone-Heated Bed

A 260 x 260 mm high-temperature zone (inner zone) at the centre of Artisan's heated bed may reach 110°C, while the outer zone's highest temperature is 80°C. The outer zone will not be heated while your model is in the inner zone, which heats up to 60°C in about 2-3 minutes, saving time and energy.

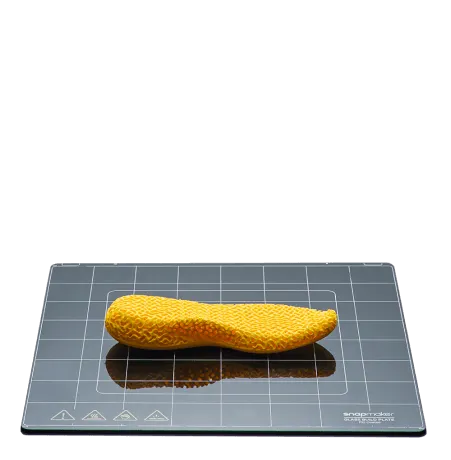

Double-sided And Multi-talented

Artisan's new build plate is comprised of more flat glass, resulting in a smoother and more sticky first layer. It has a glossy glass surface on one side and a PEI coating on the other, which aids in the adhesion of various filaments.

Quickly and Effectively

Artisan has 0.1 mm dimensional accuracy when printing at a high speed of 180 mm/s due to an optimised transmission system and motion control algorithm. Choose from Fine (40mm/s), Normal (80mm/s), Fast (120mm/s), or Extra Fast (200mm/s) modes.

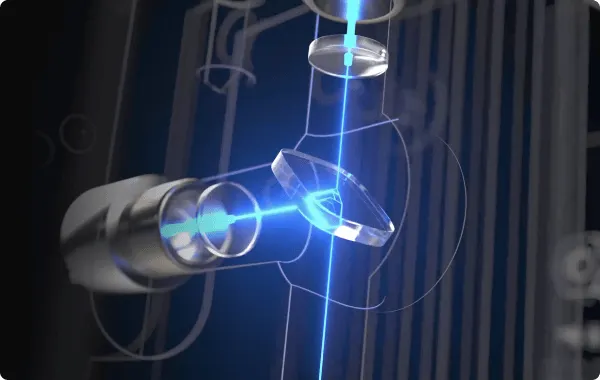

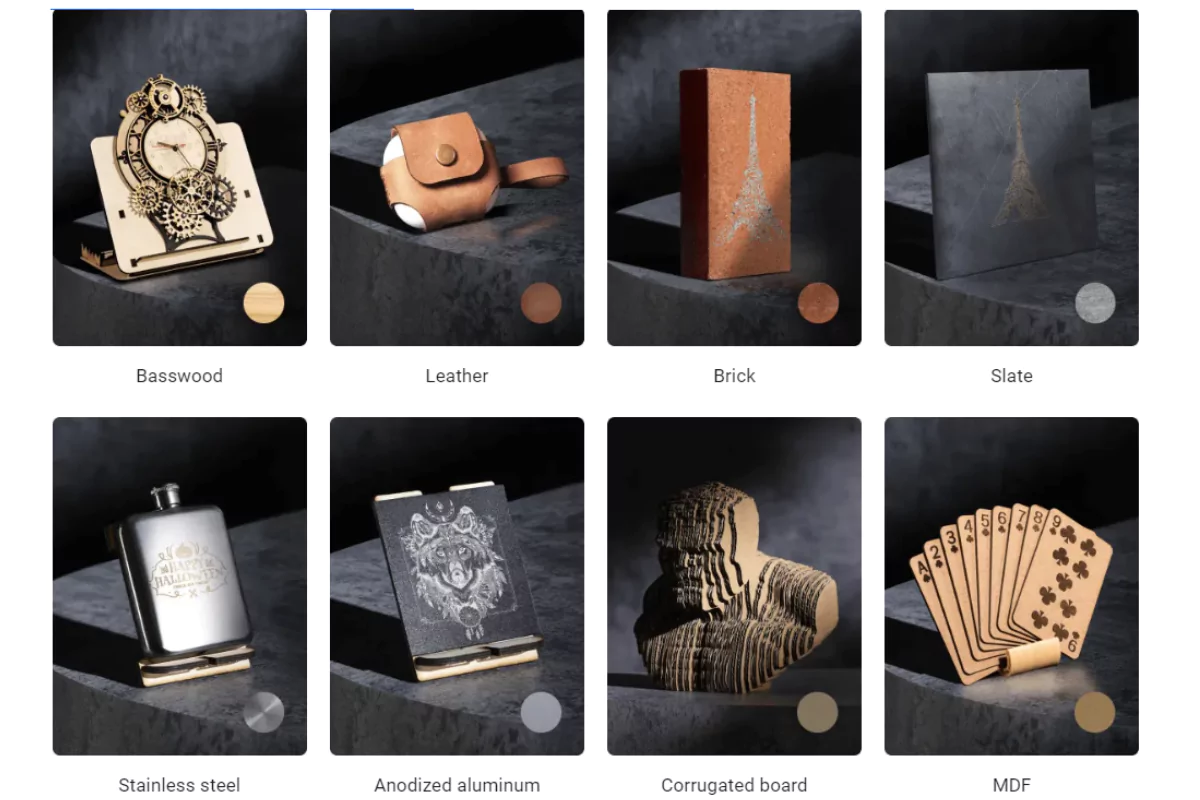

High-Power Laser Module

The laser module, powered by Laser Beam Splitters and beam shaping optics, has a 10W high power and an ultra-fine laser focus (0.05 mm x 0.2 mm). This enables high-quality laser work with precise details. Can cut through wood up to 8 mm thick in a single pass at speeds up to 8 times faster than 1.6W modules.

High-Rigidity CNC Module

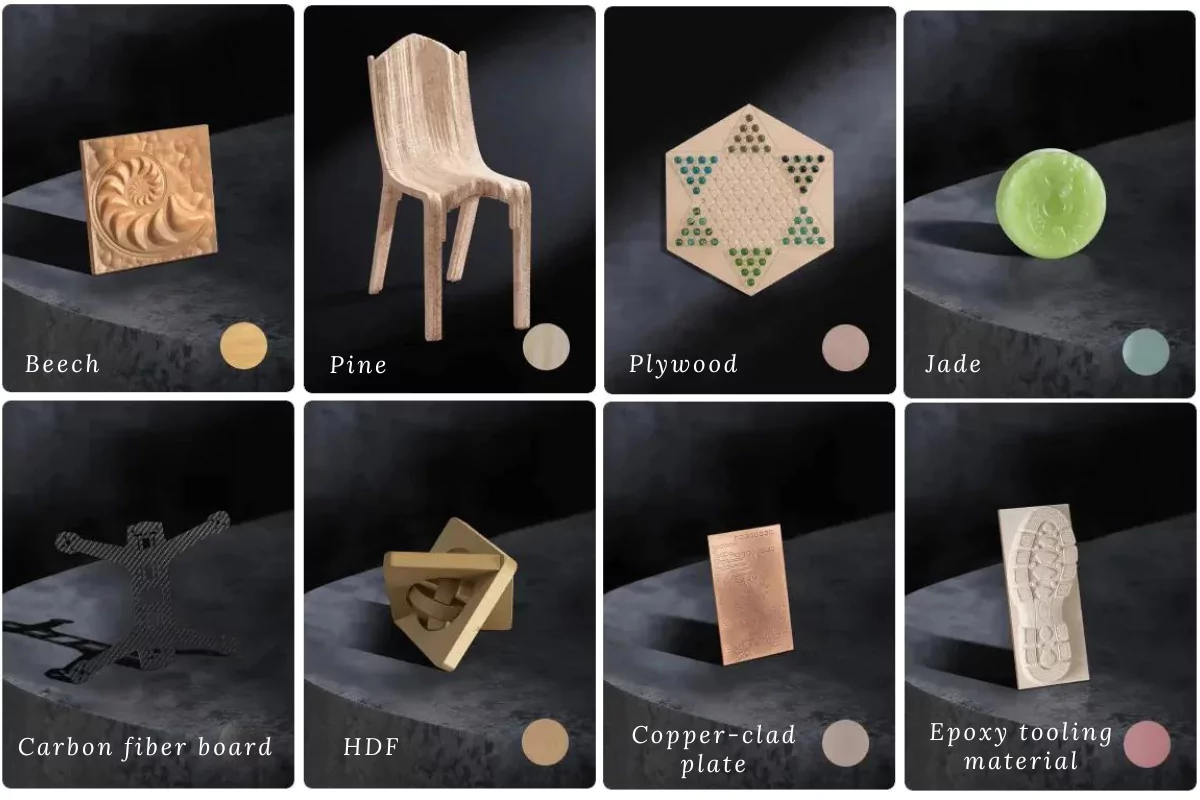

The CNC module's high-rigidity linear modules and 200W high-speed spindle (18,000 RPM) enable it to carve or cut smoothly on a variety of materials with dimensional accuracy of up to 0.2 mm. Can precision machine hardwood (beech, walnut), jade, and other hard materials.

Technical Specifications

Snapmaker Artisan 3-in-1

3D Printing

Laser Module

CNC Module

General

Materials

Controller

Work Area

400×400×400mm

Print Speed

Up to 180 mm/s

Laser Power

10W

CNC Power

200W

Related & Compatible Products

This section will show related products, compatible accessories, and recommendations.

Related Product 1

Related Product 2

Related Product 3