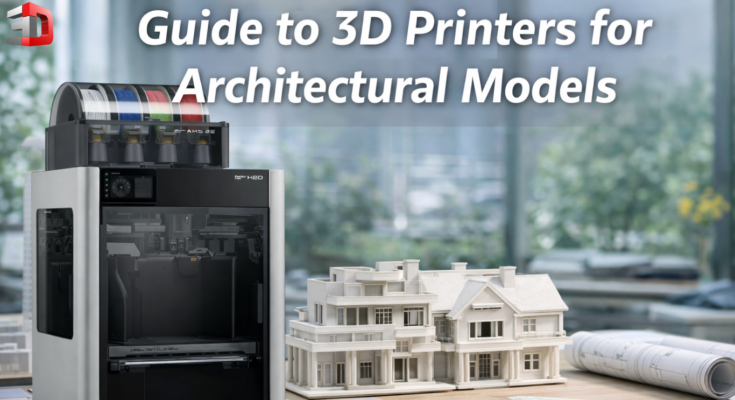

The architectural industry is experiencing a significant transformation. While digital visualization and CAD renderings have become standard, a growing number of forward-thinking firms recognize the limitations of two-dimensional presentations. Physical architectural models offer tangible benefits that digital representations cannot fully replicate. They enhance client comprehension, facilitate design validation, and establish professional credibility.

3D printing technology has emerged as a game-changing solution for architects seeking to bridge the gap between digital design and physical presentation. Unlike traditional hand-crafted models, which require weeks of labour and substantial investment, 3D-printed architectural models can be produced in days, with greater precision and consistency.

This comprehensive guide explores the technical, practical, and strategic aspects of 3D printing for architectural models, enabling architects to make informed decisions about integrating this technology into their practice.

The Evolution of Architectural Modelling: From Traditional to Digital Manufacturing

For decades, architectural models were created through manual craftsmanship, a labor-intensive process involving foam boards, basswood, acrylic, and specialized adhesives. While these hand-made models demonstrated craftsmanship and creativity, they presented significant operational challenges:

Traditional Model-Making Limitations:

-

Extended production timelines (2-4 weeks for complex models)

-

High labour costs associated with skilled craftspeople

-

Limited scalability for multiple design iterations

-

Substantial material waste due to manufacturing errors

-

Difficulty implementing design modifications mid-process

-

Inconsistent quality dependent on the individual craftsperson’s skill

The 3D Printing Revolution

The emergence of accessible 3D printing technologies has fundamentally altered this landscape. According to industry reports, the adoption of 3D printing among architecture firms globally has grown substantially over the past five years, with a particular acceleration in developed markets and emerging economies, such as India.

Current Market Adoption in India:

Leading architecture firms in major metropolitan areas, such as Mumbai, Bangalore, Delhi, Pune, and Hyderabad, have integrated 3D printing into their standard workflows. This adoption reflects both competitive necessity and demonstrated ROI in client acquisition and project delivery timelines.

Technical Specifications: What Makes a 3D Printer Suitable for Architectural Applications

Resolution and Detail Capability

Definition: Resolution, measured in micrometers (μm), determines the finest details a printer can render. It reflects the thickness of each material layer during the printing process.

Architectural Requirements:

For professional architectural models, optimal specifications include:

-

Layer height: 25-100 micrometers (0.025-0.1mm)

-

XY resolution: 25-50 micrometers in plane resolution

-

Detail rendering: Capability to represent architectural elements such as window mullions, door frames, balustrades, and surface textures with clarity

Practical Implications:

A printer with 25-micron resolution can render individual window panes, architectural detailing, and surface texture variations with photographic precision. Conversely, printers with 200+ micrometer resolution may obscure fine architectural details essential for professional presentations.

Dimensional Accuracy and Tolerance

Critical Specification: Tolerance, the deviation between designed dimensions and actual output, directly impacts model accuracy.

Industry Standards for Architectural Models:

-

Acceptable tolerance: ±0.1mm to ±0.3mm

-

Premium service tolerance: ±0.05mm to ±0.15mm

-

Consistency requirement: Uniform accuracy across all model dimensions

Practical Example:

For a 1:200 scale model, a 2-meter architectural element should print as precisely 10mm. Tolerance variations exceeding ±0.3mm become visually apparent and undermine perceived accuracy.

Build Platform Dimensions

The build platform (print bed) establishes the maximum model size and complexity that can be produced in a single print run.

Considerations for Architectural Projects:

|

Platform Size |

Typical Applications |

Advantages |

Limitations |

|

200 x 200mm |

Detailed building units, component studies |

Compact, faster prints |

Restricts larger site plans, requires part assembly |

|

300 x 300mm |

Complete residential buildings, small commercial projects |

Balanced capacity, reasonable print times |

May require assembly for larger complexes |

|

400 x 300mm+ |

Master plans, larger site contexts, comprehensive developments |

Maximum flexibility, minimal assembly required |

Extended print times, higher material costs |

Material Properties and Selection

Different material compositions offer distinct advantages for specific architectural applications:

|

Material Class |

Primary Applications |

Key Properties |

Considerations |

|

Standard Photopolymer Resin |

Detail models, client presentations |

Superior surface finish, exceptional detail clarity, broad colour palette |

Brittleness, support mark sensitivity, and cure time requirements |

|

Tough/Durable Resin |

Frequently handled models, functional prototypes |

Enhanced impact resistance, improved durability, and realistic tactile quality |

Marginally reduced detail fineness, material cost premium |

|

Engineering Nylon/Plastic |

Long-term display models, structural analysis models |

Excellent durability, flexibility, and cost-effectiveness for large prints |

Surface texture is less refined, lower detail resolution, and limited colour options |

|

Specialty Composites |

Heritage restoration projects, specialized visualization needs |

Aesthetic simulation of materials (stone, concrete texture), unique visual properties |

Material cost premium, limited supplier availability, specialized handling requirements |

3D Printer Categories: Technologies and Comparative Analysis

Fused Deposition Modelling (FDM)

Operational Principle: FDM technology extrudes heated thermoplastic filament through a precision nozzle, depositing material layer-by-layer in a controlled pattern.

Architectural Suitability: Best suited for preliminary design visualization and large-scale, lower-detail models.

Advantages:

-

Lowest initial capital investment

-

Compatibility with multiple filament types

-

Suitable for large-format printing

-

Established technology with extensive ecosystem support

-

Minimal material waste with closed-loop filament systems

Limitations:

-

Surface texture is less refined (visible layer lines)

-

Lower detail resolution compared to other technologies

-

Support structure removal is labor-intensive

-

Extended production time for complex geometries

-

Moisture sensitivity of certain filament materials

Optimal Use Cases: Firms prioritizing cost-efficiency and volume production over presentation-grade finish quality.

Stereolithography/Digital Light Processing (SLA/DLP)

Operational Principle: SLA/DLP employs a laser or digital projector to selectively cure photopolymer resin in precise patterns, building models from bottom to top.

Architectural Suitability: Optimal for professional presentations, detailed client proposals, and competition submissions.

Advantages:

-

Superior detail resolution (25-100 micrometers achievable)

-

Exceptional surface quality requiring minimal post-processing

-

Professional aesthetic suitable for high-end client presentations

-

Extensive colour and material options

-

Consistent, repeatable results across multiple prints

Limitations:

-

Higher equipment acquisition costs

-

Specialized resin handling and safety protocols are required

-

Extended post-processing, including support removal and curing

-

Smaller build platform capacity

-

Longer production timeline for large models

Optimal Use Cases: Boutique firms, high-end residential projects, international competitions, and flagship developments requiring exceptional presentation materials.

PolyJet/Multi-Material Technology

Operational Principle: Advanced systems simultaneously spray multiple material droplets, enabling full-color printing with varied material properties in a single build.

Architectural Suitability: Premium choice for large-scale practices and complex, multi-material visualization requirements.

Advantages:

-

Full-color printing without post-processing

-

Multi-material integration enabling complex material representation

-

Highest detail capability

-

Professional-grade output consistent with architectural standards

-

Rapid production of complex models

Limitations:

-

Significant capital investment restricts accessibility

-

Operational complexity requiring specialized training

-

Material costs are substantially higher than alternative technologies

-

Equipment maintenance demands specialized expertise

-

Not practical for sporadic or small-volume printing

Optimal Use Cases: Large established firms with consistent, high-volume requirements; international design competitions; complex master planning projects.

3D Printing vs. Traditional Architectural Modelling

|

Evaluation Metric |

Traditional Hand-Made Models |

3D-Printed Models |

|

Production Timeline |

2-4 weeks (complex models) |

1-3 days (including post-processing) |

|

Cost per Model |

₹15,000 – ₹50,000 (approx) |

₹5,000 – ₹25,000 (approx) |

|

Detail Consistency |

Variable (craftsperson-dependent) |

Consistent and predictable |

|

Design Modification Time |

1-2 weeks (partial rebuilding) |

1-24 hours (file revision + reprint) |

|

Iteration Feasibility |

Limited (cost-prohibitive) |

Extensive (economically viable) |

|

Professional Presentation Quality |

Highly variable |

Reliably professional |

|

Scalability |

Limited by labour availability |

Unlimited (subject to equipment capacity) |

|

Long-term Durability |

Moderate to poor |

Excellent (material dependent) |

Strategic Advantages of 3D Printing

1. Accelerated Design Development

3D printing enables rapid iteration of design alternatives. Architects can feasibly produce multiple conceptual models for comparative analysis, informing design decisions with greater rigour than traditional single-prototype approaches permit.

2. Economic Optimization

While per-unit printing costs vary, cumulative project expenses often prove lower than traditional methods, particularly for iterative projects or firms requiring multiple models annually. Predictable pricing eliminates cost overrun risks inherent in labor-intensive craftsmanship.

3. Temporal Efficiency

Compressed production timelines from digital design to physical model in 24-48 hours and align with accelerated project delivery schedules, and facilitate responsive client engagement.

4. Design Validation

Physical models enable three-dimensional spatial evaluation, impossible to achieve through digital visualization alone. Clients and stakeholders develop significantly improved spatial comprehension when examining tangible models.

5. Professional Credibility

High-quality 3D-printed models communicate technological sophistication and professional standards, enhancing client confidence in proposed designs and firm capabilities.

Best Practices for Architectural Model 3D Printing

CAD File Preparation and Optimization

Pre-Print Checklist:

-

Geometry Check: Make sure your model is fully enclosed with no gaps or holes, so it’s “watertight.”

-

Wall Thickness: Ensure that parts of your model are at least 1-2mm thick. Anything thinner than 0.5mm might cause problems during printing.

-

Check the Size: Double-check that the model’s dimensions match your design. If necessary, adjust the size or recalibrate.

-

Support Removal: Design your model so that it’s easy to remove any support structures after printing. Avoid designs with too many overhangs that need a lot of support.

-

File Format: Save your model in an STL or OBJ file format with the right mesh resolution for printing.

Quality Check:

Many 3D printing services, like 3Ding, offer free reviews of your file to check for potential issues before printing begins. This helps avoid mistakes and ensures a smoother process.

Print Orientation and Support Strategy

Strategic Positioning Considerations:

-

Layer Visibility: Orient models to minimize visible layer lines on prominent architectural facades

-

Support Optimization: Position to reduce support material contacting visible surfaces, thereby minimizing post-processing requirements

-

Structural Integrity: Orient complex geometries to ensure adequate internal support without compromising detail quality.

-

Print Time Efficiency: Optimize orientation to balance quality with production timeline

Post-Processing and Finishing Protocols

Support Structure Removal:

-

Careful disassembly, preventing surface damage

-

Controlled dissolution using appropriate solvents (resin-dependent)

-

Fine finishing of support contact points

Surface Refinement:

-

Light sanding with high-grit abrasives (220-400 grit) for refined surfaces.

-

Acetone vapour smoothing (resin models) for enhanced professional appearance

-

Strategic texture application simulating architectural materials

Colour Application and Detailing:

-

Precision painting replicating architectural material palettes

-

Landscape and site context integration

-

Clear protective coating application for durability

Timeline Allocation: Professional-quality finishing typically requires 1-3 days post-print.

3D Printing in Architectural Practice: Strategic Implementation

Workflow Integration

Optimal Integration Points:

-

Design Development Phase: Generate iterative models exploring design alternatives

-

Client Presentation: Produce professional models for investor pitches, municipal approvals, and stakeholder engagement

-

Construction Documentation: Create functional models supporting contractor coordination and assembly visualization

-

Marketing and Competition: Develop portfolio-quality models for practice promotion and design competition submissions

Decision Framework: In-House Equipment vs. Professional Services

In-House Equipment Investment Justifiable When:

-

Annual printing volume exceeds 20-30 models

-

Printing requirements are consistent and predictable

-

The firm possesses technical expertise for equipment operation and maintenance.

-

Sufficient capital budget accommodates equipment and training costs

-

Facility space accommodates equipment and material storage

Professional Services, Preferably When:

-

Printing requirements are sporadic or project-dependent

-

Firms prioritize service flexibility without capital investment

-

Quality, consistency,y and professional standards are paramount

-

Complex material requirements exceed equipment capabilities

-

Project timelines demand rapid turnaround with assured quality

Professional 3D Printing Services: 3Ding

For architecture firms prioritizing service quality, consistency, and operational simplicity, professional 3D printing services offer significant advantages.

3Ding’s Capabilities and Service Model

3Ding specializes in architectural and product visualization through professional 3D printing services:

Service Offerings:

-

Multiple material options (photopolymer resins, engineering plastics, composites)

-

Professional post-processing and finishing services

-

Expert CAD file consultation and optimization

-

Expedited production services (24-48 hour turnaround)

-

Full-service delivery across major Indian metropolitan areas

-

Competitive pricing with transparent quotation structure

Quality Assurance Standards:

-

Consistent print quality across all projects

-

Professional surface finishing and detailing

-

Material selection consultation based on application requirements

-

Expert guidance on design optimization for printability

Service Advantages:

-

Capital Efficiency: Eliminates equipment investment, freeing capital for core architectural services

-

Operational Simplicity: Outsources technical complexity, training, and maintenance responsibilities

-

Scalability: Accommodates volume fluctuations without efficiency degradation

-

Quality Consistency: Professional standards maintained across all projects

-

Expertise Access: Benefits from specialized technical knowledge and equipment diversity

Working with 3Ding: The Process

Step 1: File Submission Submit CAD files (typically Revit, SketchUp, or AutoCAD exports) to 3Ding for technical review.

Step 2: Design Assessment 3Ding’s technical team evaluates printability, recommends material and finishing options, and provides detailed cost estimates and timeline projections.

Step 3: Approval and Production Upon approval, 3Ding produces models using appropriate technology, ensuring quality standards.

Step 4: Quality Assurance All models undergo rigorous quality inspection before delivery.

Step 5: Delivery and Support Models are professionally packaged and delivered with consultation on presentation and handling protocols.

Key Considerations for Architectural Model Selection

Material Selection Guide

For Professional Client Presentations: Recommend photopolymer resin printing with professional finishing—delivers exceptional detail and aesthetic quality, justifying presentation context.

For Functional Design Analysis: Suggest tough resin or nylon printing and prioritize durability for repeated handling and structural evaluation.

For Large-Scale Site Plans: Consider multi-material or high-capacity printing that enables comprehensive site context representation in minimal assembly requirements.

For Heritage or Specialized Projects: Explore specialty composite materials that enable aesthetic simulation of authentic materials and specialized visualization requirements.

Timeline and Budget Planning

Typical Project Timeline:

-

File preparation: 2-5 days (approx)

-

Printing: 1-2 days (variable based on complexity)

-

Post-processing and finishing: 1-3 days

-

Total estimated timeline: 4-10 days (approx)

Budget Range for Professional Architectural Models:

-

Basic single-building model: ₹5,000 – ₹12,000 (approx)

-

Complex residential or commercial project: ₹12,000 – ₹25,000 (approx)

-

Large master plan or multi-building complex: ₹25,000 – ₹50,000+ (approx)

Professional services like 3Ding provide detailed quotations enabling precise budget planning before production commitment.

Conclusion: The Strategic Imperative for Architectural Practice

3D printing represents more than technological novelty, and it constitutes a strategic capability differentiating progressive architectural practices in increasingly competitive markets. The combination of accelerated timelines, superior quality consistency, and economic viability positions 3D-printed models as standard practice rather than a premium offering.

Whether through in-house equipment investment or professional service engagement, architects should evaluate 3D printing integration as a priority strategic initiative. The technology directly enhances client engagement, supports design validation, and establishes professional credibility.

Next Steps

For architects considering 3D printing implementation:

-

Evaluate current practice requirements – Assess printing volume, quality standards, and timeline needs

-

Explore service options – Investigate both equipment investment and professional service viability

-

Consult with specialists – Engage with professionals who understand architectural requirements and technical capabilities

3Ding offers a complimentary consultation for architects exploring 3D printing integration:

-

Technical file review assessing printability

-

Customized quotations with detailed timelines

-

Material selection guidance based on project requirements

-

Professional service delivery, ensuring consistent quality standards

Contact 3Ding to discuss how professional 3D printing services can enhance your architectural practice and client presentations.