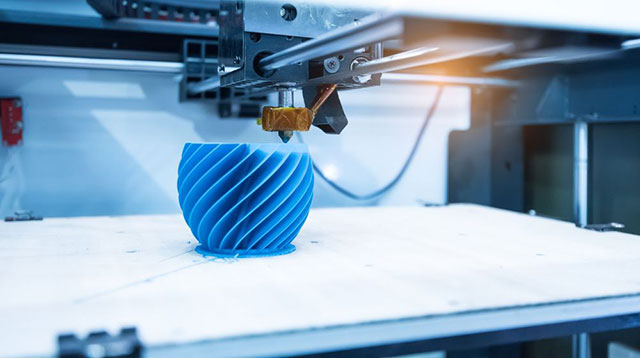

Many businesses already use industrial-grade 3D printers in their manufacturing procedures, therefore we want to pinpoint the sectors that, in our opinion, stand to gain the most from additive manufacturing. By examining these sectors, it is simple to see how and why professional 3D printers are revolutionising the manufacturing sector as a whole.

Aerospace

Some of the highest criteria for component performance are found in the aircraft sector. Aerospace components need to be as light as possible while withstanding high temperatures, harsh chemicals, and frequent loads.

Failure is simply not an option when an aeroplane is transporting people or goods since single part failures frequently lead to whole system breakdowns. Aerospace engineers have turned to 3D printing inspection tooling to cut costs for low-volume components since part quality is crucial for aeroplanes.

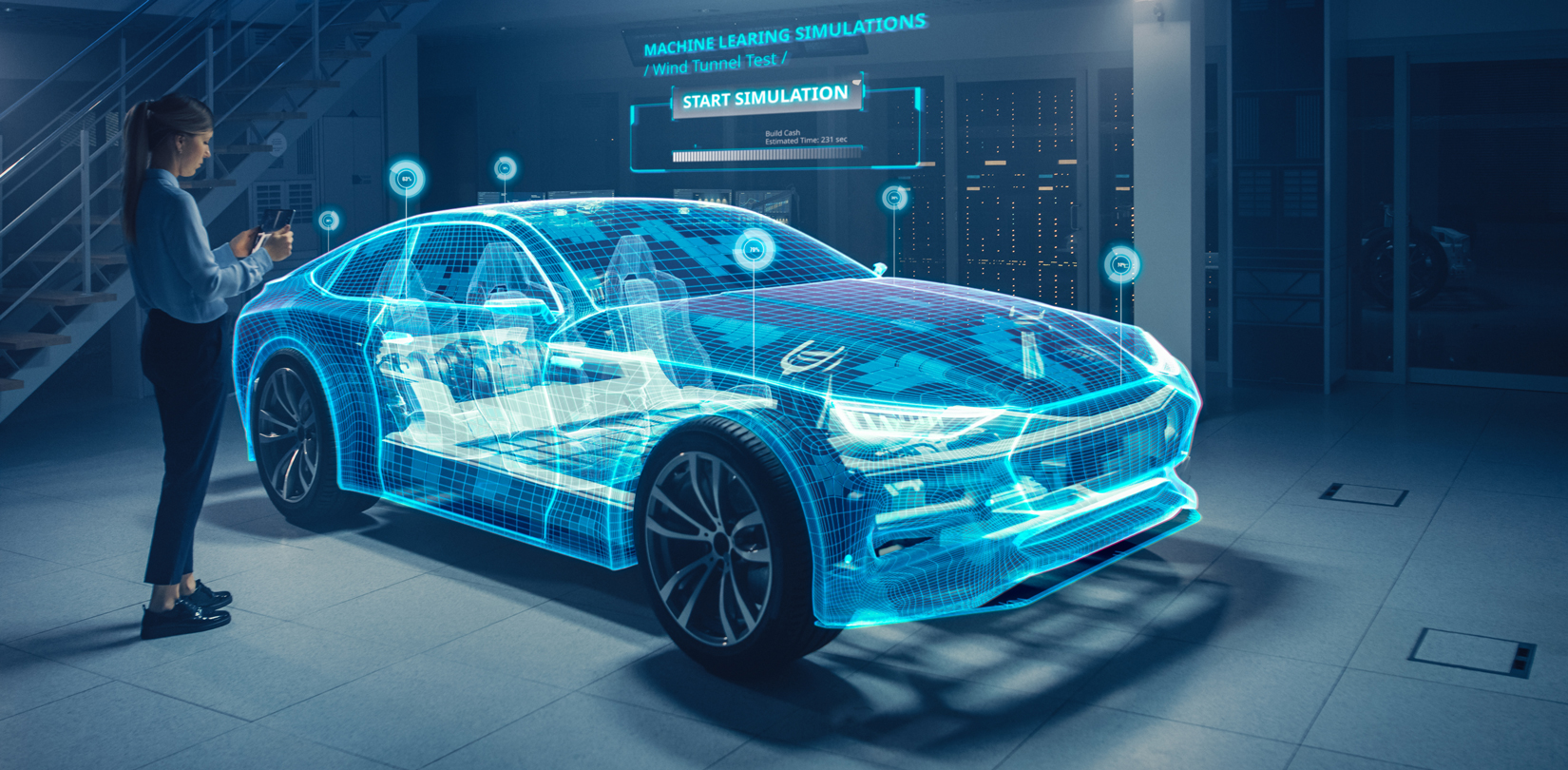

Automotive

With prominent corporations like Audi employing 3D printers, the automobile sector has been leading the way in additive manufacturing. Not only are the Audis of the world employing 3D printers; but so are race car teams and the original equipment manufacturers of every automaker.

The usefulness of 3D printing for car manufacturers initially centered on creating the fixtures and tools that facilitate the production process. Fixtures, cradles, and prototypes are the most typical parts printed by the automobile industry. These items need to be rigid and sturdy as well as long-lasting.

Manufacturing

Industrial 3D printers are radically upending the long-established manufacturing business, from jigs and fixtures to final tooling. Companies may now produce specialized, low-volume tooling and fixtures for a fraction of the cost of old methods, freeing up designers’ and engineers’ time for items that generate money.

Mall producers now have access to the same benefits from a professional 3D printer as huge, international manufacturers, which helps to enhance and expedite operations while reducing downtime.

Robotics

Several characteristics make effective robotics parts complement 3D printing capabilities well, from customizability to reduced weight. It is expensive to produce and necessitates unique designs for components like grippers and sensor mounts for various applications.

Robotics experts employ 3D printers for end-of-arm tooling and end-use parts, ranging from gripper fingers to full robot components, to minimise the total weight of the product and enable the tools to move more quickly and carry greater loads.

Conclusion

Industrial 3D printing has advanced over time to offer several advantages to various business industries. These advantages include less material consumption, decreased prices, and increased productivity. Additionally, it enables engineers and designers to produce everything from visual aids to prototypes and fittings.

In reality, there are countless opportunities for 3D printing to be used in various industries for product development and manufacturing. If you’re interested in outsourcing 3D printing for your sector of business, get in touch with us, your 3D printing services in Chennai provider to get expert advice.

Wow ! 3D Printing sounds interesting. Can we make a 3D print of Companies Logo as well? Is that possible? If Yes, then the 3D printing would be useful for almost all the industries as everyone has their own Logo and 3D printing can be used for Branding purposes.

Nice blog about 3D printing. to check about 3d spare parts for big industries you can reach here.