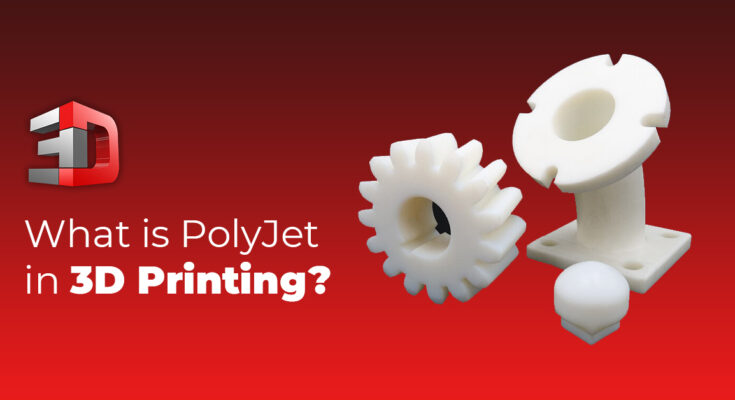

What is PolyJet in 3D Printing?

PolyJet is an amazing 3D printing technology, which creates smooth, accurate parts, tooling, and prototype. It can produce complicated geometries and thin walls using a wide array of materials accessible with any technology. This is because it has microscopic layer resolution and accuracy down to 0.014mm. Capabilities and Guidelines of PolyJet Design The capabilities and guidelines help in enhancing cosmetic appearance, improving part manufacturability, as well as reducing the overall time required for production. US Metric Maximum Part Size 19.3 in. x 15.4 in. x 7.9 in. 490mm x 390mm x 200mm Layer Thickness 0.00118 in. 30 microns Minimum Feature …

What is PolyJet in 3D Printing? Continue Reading...