The evolution of 3D printing technology has reached a pivotal moment for Indian manufacturers, engineering teams, and design professionals. The Bambu Lab H2S represents a significant leap forward in accessible industrial-grade additive manufacturing, which combines precision, speed, and multi-functional capabilities in a single integrated platform. For businesses seeking to accelerate product development, reduce prototyping costs, and maintain competitive advantage, understanding what sets this system apart becomes essential.

In India’s rapidly expanding manufacturing and innovation ecosystem, access to reliable professional 3D printing solutions directly impacts time-to-market, design iteration speed, and operational efficiency. The Bambu Lab H2S addresses these critical business needs while remaining accessible to organizations transitioning from conventional desktop systems to production-capable equipment.

What is the Bambu Lab H2S 3D Printer?

The Bambu Lab H2S is an all-in-one manufacturing hub that extends beyond conventional 3D printing. This professional-grade system integrates high-volume fused deposition modeling with multi-color printing, laser cutting and engraving, and digital cutting capabilities—all within a compact footprint suitable for workshop and office environments.

With a substantial 340×320×340 mm³ build volume, the H2S delivers 120% more printing capacity than typical prosumer systems. This translates to fewer assembly requirements for large parts, reduced joint weaknesses, and the ability to produce functional prototypes or end-use components in single print runs.

Unlike entry-level desktop printers, the Bambu Lab 3D printer incorporates industrial-grade features such as active chamber heating up to 65°C, a 350°C hot end for engineering materials, and Vision Encoder Technology that maintains precision below 50 micrometers throughout the printer’s operational life.

Bambu Lab H2S Core Capabilities at a Glance

Capability |

Specification |

Business Advantage |

|

Build Volume |

340×320×340 mm³ |

Single-piece large parts without assembly |

|

Precision |

<50 μm with Vision Encoder |

Machine-shop accuracy without post-processing |

|

Hotend Temperature |

Up to 350°C |

Engineering-grade materials support |

|

Chamber Heating |

Up to 65°C active heating |

Warp-free prints in advanced polymers |

|

Print Speed |

Up to 30% faster than comparable systems |

Compressed project timelines |

|

Laser Cutting |

10W module cuts 5mm materials |

Integrated multi-material processing |

|

Monitoring System |

23 sensors + 3 cameras |

Real-time failure prevention |

Key Features and Core Technology of Bambu Lab H2S

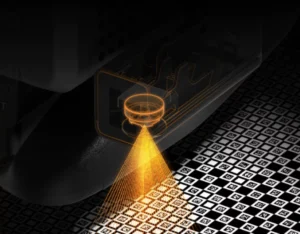

Vision Encoder Technology and Precision Engineering

The Bambu Lab H2S 3D Printer introduces Vision Encoder Technology, which is a self-correcting positioning system that compensates for mechanical wear and drift over time. This innovation ensures consistent dimensional accuracy below 50 micrometers, addressing a common limitation in 3D printing where precision degrades as components age.

Precision advantages include:

-

Automatic hole and contour compensation for perfect mechanical fits

-

Bearings and fasteners installed without manual adjustment

-

Consistent part dimensions across extended production runs

-

Elimination of calibration drift over time

-

Machine-shop level accuracy directly from prints

The servo-controlled extrusion system, combined with eddy current nozzle sensors, delivers smooth layer transitions and sharp edge definition—producing production-quality surface finishes that often eliminate secondary operations.

Intelligent Monitoring and Failure Prevention

Twenty-three sensors and three integrated cameras continuously monitor the printing process, collecting over 20,000 data points per second. AI-powered vision monitoring detects extrusion anomalies, filament grinding, and layer adhesion issues in real-time, automatically pausing or correcting problems before they result in failed prints.

The comprehensive monitoring system includes:

-

Filament run-out and tangle detection

-

Real-time extrusion quality analysis

-

Temperature monitoring across the hot end and the chamber

-

Airflow and ventilation verification

-

Flame detection and emergency shut-off capability

-

Door sensor for operational safety

-

Pre-flight checklist with automatic calibration

This proactive approach dramatically reduces wasted material and operator intervention time, particularly valuable in production environments where unattended overnight printing is common.

Active Vibration Compensation

High-speed printing typically introduces mechanical vibrations that compromise surface quality and dimensional accuracy. The H2S employs active vibration compensation algorithms that neutralize resonance dynamically, enabling print speeds up to 30% faster than comparable systems without sacrificing quality.

The DynaSense extruder with permanent magnet synchronous motor (PMSM) delivers 67% more extrusion force compared to standard systems, supporting high-flow printing with challenging materials at accelerated speeds.

Performance, Speed, and Print Quality

Print speed alone doesn’t define productivity, but reliability and first-time-right success rates determine actual throughput in professional settings. The Bambu Lab 3D printer architecture combines speed with consistency through closed-loop control systems that continuously adjust temperature, extrusion rate, and motion parameters based on sensor feedback.

Performance Specifications of Bambu Lab H2S

Performance Metric |

Specification |

Practical Impact |

|

Max Toolhead Speed |

1,000 mm/s |

Rapid non-printing movements |

|

Max Acceleration |

20,000 mm/s² |

Quick direction changes without ringing |

|

Standard Flow Rate |

40 mm³/s |

Efficient standard material printing |

|

High Flow Rate (Optional) |

65 mm³/s |

Accelerated large-volume jobs |

|

Layer Precision |

<50 μm maintained |

Consistent quality over printer lifetime |

|

Operating Noise |

<50 dB |

Suitable for office environments |

For businesses operating multiple shifts or managing tight project deadlines, the H2S’s reliability translates to predictable capacity planning. Projects that previously required several days of printing can be completed in substantially less time without the quality compromises typically associated with accelerated print speeds.

Material Compatibility and Print Capabilities of Bambu Lab H2S

Engineering-Grade Material Support

The combination of a 350°C hot end and a 65°C actively heated chamber unlocks a broad spectrum of professional materials. The system reliably processes standard filaments like PLA and PETG alongside engineering thermoplastics, including polycarbonate, polyamide, PPA-CF, PPS, and glass-fiber reinforced composites.

Supported material categories:

-

Standard Materials: PLA, PETG, TPU for prototyping and visual models

-

Engineering Polymers: ABS, ASA, PC, PA for functional parts

-

High-Performance Materials: PPA-CF/GF, PPS, PPS-CF/GF for demanding applications

-

Composite Materials: Carbon-fiber and glass-fiber reinforced variants

-

Support Materials: PVA, BVOH for complex geometry support

This material versatility eliminates the common scenario where businesses require multiple specialized printers for different applications. A single Bambu lab H2S can handle both aesthetic prototypes in standard materials and functional testing with high-performance polymers that simulate final production material properties.

Multi-Color Printing Capability

When paired with Bambu Lab’s AMS (Automatic Material System), the Bambu Lab H2S enables seamless multi-color printing without manual intervention. This capability proves particularly valuable for:

-

Architectural models with color-coded sections

-

Product visualization prototypes showing material transitions

-

Educational demonstrations requiring visual differentiation

-

Assembly instructions with color-based guidance

-

Brand-accurate product samples

Servo-controlled extrusion and intelligent filament management minimize purge waste during colour transitions, making multi-material printing economically viable for commercial applications.

Integrated Multi-Function Platform

Beyond 3D Printing: Laser Cutting and Engraving

The Bambu Lab H2S 3D printer includes a 10W laser module capable of cutting and engraving across diverse materials. This integration eliminates the need for separate laser cutting equipment and streamlines workflows requiring both additive and subtractive processes.

Laser Specification |

Details |

|

Laser Power |

10W semiconductor laser |

|

Wavelength |

455nm (blue light) for engraving |

|

Spot Dimension |

0.03 × 0.14 mm² for fine detail |

|

Max Cutting Thickness |

5mm basswood plywood |

|

Engraving Area |

310 × 260 mm² |

|

Max Engraving Speed |

400 mm/s |

|

Positioning Accuracy |

<0.3mm with camera-assisted alignment |

Laser-compatible materials include:

-

Wood products (plywood, MDF, basswood)

-

Acrylic sheets (dark colours for optimal cutting)

-

Leather and PU leather

-

Rubber materials

-

Metal sheets (for engraving)

-

Stone and tile (for surface engraving)

The air assist system maintains clean cuts by removing smoke and debris during laser operations, while the integrated ventilation system ensures safe fume extraction.

Digital Cutting and Drawing

The digital cutting function handles materials up to 0.5mm thick, supporting applications in packaging design, signage production, and mixed-media fabrication.

Digital cutting capabilities:

-

Paper cutting for packaging prototypes

-

Vinyl cutting for signage and labels

-

PU leather for product samples

-

PVC materials for templates

-

Drawing function with a 10.5-12.5mm pen support

-

Cutting area: 300 × 285 mm²

-

Blade pressure range: 50-600 gf

Automatic material detection recognizes cutting mat type and adjusts parameters accordingly, simplifying setup for operators switching between material categories.

Industry Use Cases in the Indian Market

Manufacturing and Rapid Prototyping

Indian manufacturing firms increasingly adopt additive manufacturing to compress product development cycles and reduce tooling costs. The Bambu Lab H2S 3D printer enables engineers to transition from CAD design to physical validation within hours, rather than weeks, thereby accelerating design iteration and reducing dependency on external prototyping services.

Key manufacturing applications:

-

Functional prototypes for design validation

-

Tooling fixtures and manufacturing jigs

-

Custom end-effectors for robotics

-

Small-batch production runs

-

Replacement parts for legacy equipment

-

Quality control gauges and inspection tools

The large build volume accommodates full-scale functional prototypes without requiring assembly of multiple smaller parts, particularly benefiting automotive component suppliers, consumer appliance manufacturers, and industrial equipment producers operating across India’s manufacturing clusters.

Engineering Research and Development

Technical universities and corporate R&D departments utilize the H2S for advanced material research, structural testing, and concept validation. The system’s ability to process carbon-fiber and glass-fiber reinforced composites enables testing of lightweight structural components under real-world load conditions.

The precision and repeatability of the H2S support academic research requiring documented process parameters and reproducible results—requirements often difficult to achieve with less sophisticated equipment.

Education and Skill Development

As India strengthens its technical education infrastructure, institutions require reliable 3D printing systems that expose students to industry-standard technology. The H2S’s combination of professional capabilities and comprehensive safety features makes it suitable for supervised student use, providing hands-on experience with equipment that matches current industry practices.

Educational benefits include:

-

Hands-on experience with production-grade equipment

-

Multi-disciplinary project support across engineering domains

-

Integrated laser and cutting functions for comprehensive training

-

Safe operation with flame detection and emergency shut-off

-

Real-world material experience prepares students for the industry

Startups and Design Consultancies

Product startups and design firms serve clients across diverse industries, requiring flexible manufacturing capabilities. The Bambu Lab H2S functions as a versatile production tool capable of handling low-volume manufacturing runs, custom client prototypes, and design validation samples from a single platform.

The multi-mode environment control system automatically adjusts chamber ventilation based on material type, sealed recirculation for engineering polymers, fresh airflow with filtration for standard materials, and fume extraction during laser operations.

Why Bambu Lab H2S is a Superior Choice

Comparative Advantagesof Bambu Lab H2S

Feature Category |

Bambu Lab H2S |

Typical Desktop Systems |

|

Build Volume |

340×320×340 mm³ |

Usually 220×220×250 mm³ |

|

Precision Maintenance |

Vision Encoder self-correction |

Manual recalibration required |

|

Chamber Heating |

Active 65°C heating |

Passive or none |

|

Monitoring |

23 sensors + 3 cameras + AI |

Basic sensors, no AI |

|

Material Range |

Engineering composites supported |

Limited to basic materials |

|

Multi-Function |

3D print + laser + digital cut |

Single function only |

|

Failure Detection |

Real-time AI prevention |

Manual monitoring required |

|

Hotend Temperature |

350°C for advanced materials |

Usually 260-280°C maximum |

Superior Build Quality and Longevity

The die-cast aluminium alloy chassis provides structural rigidity that minimizes vibration and thermal distortion. Quick-swap nozzles enable tool-free hot end changes in seconds, supporting rapid transitions between material types without extended downtime.

Durability features:

-

Rigid frame construction minimizing deflection

-

Fire-resistant protective housing

-

Hardened steel extruder gear and nozzle

-

All-metal hot end for thermal stability

-

Industrial-grade motion components

-

Closed-loop control for consistent performance

Comprehensive Connectivity Options

The H2S supports cloud-based remote monitoring, fully offline operation for sensitive work, and MQTT integration for custom automation workflows. Mobile notifications provide real-time updates on print progress and safety events, enabling responsive management of production schedules across distributed facilities.

Connectivity features:

-

Cloud connectivity for remote monitoring and job submission

-

Fully offline operation for confidential projects

-

MQTT developer port for custom integration

-

Mobile app with real-time notifications

-

WiFi 802.11 a/b/g/n support (2.4GHz and 5GHz)

-

USB port for standalone operation

-

5-inch touchscreen for local control

Why Buy the Bambu Lab H2S in India from 3Ding

Authorized Distribution and Genuine Products

Purchasing professional 3D printing equipment from authorized suppliers like 3Ding ensures genuine products, valid warranties, and access to manufacturer support channels. Grey-market imports often lack proper documentation, may not include required safety certifications for Indian markets, and typically provide no recourse for defective units or replacement parts.

Benefits of authorized purchasing:

-

Genuine Bambu Lab products with full warranty

-

Proper electrical certifications for Indian safety standards

-

Access to manufacturer firmware updates and support

-

Legitimate replacement parts availability

-

Recourse for defective equipment or issues

-

Compliance with Indian import and regulatory requirements

Nationwide Delivery and Local Support

3Ding maintains a delivery infrastructure covering major Indian cities and industrial regions, ensuring reliable logistics and reasonable shipping timelines. Local technical support teams provide installation assistance, operator training, and troubleshooting in familiar business contexts—addressing language preferences and understanding Indian operational environments.

Training and Application Development

Beyond equipment supply, 3Ding offers training programs covering machine operation, material selection, print optimization, and preventive maintenance. For organizations new to professional additive manufacturing, this knowledge transfer significantly reduces the learning curve and accelerates return on investment.

Support services include:

-

Installation and commissioning assistance

-

Operator training for technical teams

-

Material selection guidance for specific applications

-

Print parameter optimization for quality and speed

-

Preventive maintenance training

-

Application development consultation

-

Ongoing technical support in local languages

Technical Specifications Summary

Core System Specifications of Bambu Lab H2S

Category |

Specification |

|

Printing Technology |

Fused Deposition Modelling (FDM) |

|

Build Volume |

340 × 320 × 340 mm³ |

|

Physical Dimensions |

492 × 514 × 626 mm³ |

|

Net Weight |

30 kg (30.5 kg Laser Edition) |

|

Nozzle Diameter |

0.4mm included; 0.2, 0.6, 0.8mm supported |

|

Filament Diameter |

1.75mm standard |

|

Layer Precision |

<50 μm with Vision Encoder |

|

Max Print Speed |

Up to 30% faster than comparable systems |

|

Operating Temperature Range |

10-30°C (3D printing), 0-35°C (laser) |

|

Power Requirements |

100-240V AC, 50/60Hz |

|

Max Power Consumption |

2050W @220V / 1170W @110V |

Advanced Features of Bambu Lab H2S

Feature |

Details |

|

Extruder Motor |

High-precision PMSM servo motor |

|

Build Plates |

Textured PEI, Smooth PEI plates |

|

Max Bed Temperature |

120°C |

|

Active Chamber Heating |

Up to 65°C controlled heating |

|

Cameras |

3 integrated (Live view, nozzle, tool head) |

|

Sensors |

23 sensors for comprehensive monitoring |

|

Neural Processing |

2 TOPS for AI monitoring |

|

Safety Features |

Flame detection, emergency stop, door sensor |

|

Filtration |

G3 pre-filter with multi-mode ventilation |

FAQ’s related to Bambu lab H2S

Does the H2S support laser and cutting functions?

Yes. The Bambu Lab H2S supports laser cutting, laser engraving, and digital cutting, along with high-precision 3D printing. This all-in-one system enables multiple fabrication tasks on a single platform, making it ideal for professional prototyping, manufacturing, and design applications.

Is H2S or H2D better?

It depends on your needs. The H2S offers a larger build volume, making it better for large parts and single-piece prints, while both models share the same core precision, AI monitoring, and multi-function capabilities. Choose Bambu Lab H2S for bigger prototypes and tooling, and H2D for more compact workflows.

How to set up Bambu Lab H2S?

Setup is straightforward: place the machine on a stable surface, connect power, install the build plate, load filament, and connect via Wi-Fi or USB. The 5-inch touchscreen guides setup, and the printer runs automatic calibration and system checks before the first print. Authorized suppliers like 3Ding provide installation and training support.

Where to buy Bambu Lab H2S in India?

Buy the Bambu Lab H2S in India from authorized suppliers like 3Ding to ensure genuine products, valid warranty, firmware updates, and local technical support. 3Ding offers nationwide delivery, installation assistance, and operator training.

How to use Bambu Lab H2S?

Prepare your model in Bambu Studio, send it via Wi-Fi, cloud, or USB, and start 3D printing using the touchscreen. The H2S handles auto-calibration, material settings, and chamber control automatically. Prints can be monitored remotely using the mobile app with live camera feeds.

Conclusion: Elevating Manufacturing Capability

The Bambu Lab H2S 3D printer represents a strategic investment for Indian organizations seeking to enhance their design and manufacturing capabilities. By combining precision, speed, reliability, and multi-functional versatility in an accessible professional platform, it addresses the practical needs of modern engineering and production environments.

Key advantages include:

-

Industrial-grade precision with self-correcting Vision Encoder Technology

-

Comprehensive material support from PLA to carbon-fiber composites

-

Integrated multi-function platform eliminating equipment redundancy

-

AI-powered monitoring prevents failures before they occur

-

Large build volume supporting full-scale functional prototypes

-

Professional laser cutting and digital cutting capabilities

-

Extensive safety features for unattended operation

For businesses ready to reduce prototyping timelines, eliminate outsourcing dependencies, and maintain competitive advantage through rapid iteration capability, the H2S delivers measurable operational benefits. The system’s industrial-grade features and comprehensive automation lower the technical barriers that previously limited professional additive manufacturing adoption.

Ready to explore how the Bambu Lab H2S can transform your design and manufacturing workflow? Contact 3Ding today to schedule a consultation, request a demonstration, or discuss application-specific implementation strategies. As an authorized supplier with nationwide coverage across India, 3Ding provides the local expertise and support infrastructure necessary to maximize your investment in professional 3D printing technology.

Discover the difference that precision engineering, intelligent automation, and integrated multi-function capability bring to your operations. Connect with 3Ding’s technical team to begin your journey toward faster, more efficient, and more cost-effective product development.