Medical care in India is changing in exciting ways, thanks to a powerful new technology called 3D printing in healthcare. What once seemed like something from a movie is now helping doctors treat patients better every single day. Hospitals across India are using 3D printing to save lives, create custom medical devices, and give patients faster, more accurate treatment than ever before.

In this comprehensive guide, you’ll discover how 3D printing for healthcare actually works, explore real-world examples of medical 3D printing being used in Indian hospitals right now, and learn about the different applications from custom prosthetics to surgical planning. Whether you’re a healthcare professional seeking to understand this technology or someone curious about modern medicine, this article will explain exactly how 3D printing in hospitals is transforming patient care and why it matters for the future of healthcare in India.

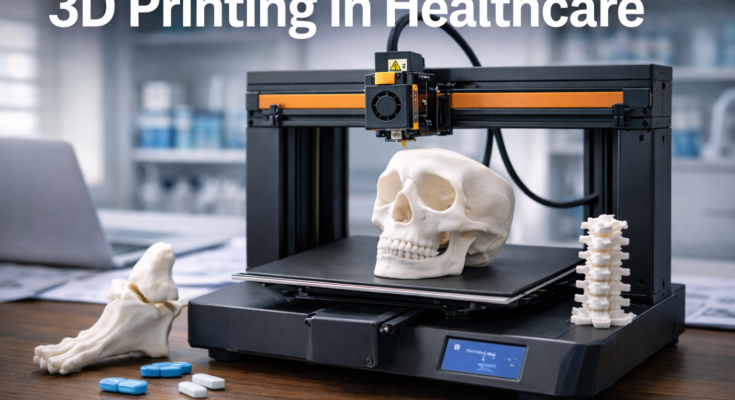

Understanding 3D Printing for Healthcare

3D printing, also known as additive manufacturing, creates three-dimensional objects by building them layer by layer from digital designs. Think of it like a regular printer, but instead of putting ink on paper, it deposits materials like bio-compatible substances to create physical objects.

In healthcare, 3D printing has opened doors to personalized medicine, custom medical devices, and surgical solutions tailored to each patient’s unique anatomy. Medical 3D printing is no longer experimental—it’s actively transforming how doctors diagnose, plan surgeries, and treat patients every single day.

Real-World Applications of 3D Printing in Medicine

Custom Prosthetics and Orthotics

One of the most significant applications of 3D printing in medicine is the creation of custom prosthetic limbs and orthotic devices. Traditional prosthetics can cost lakhs of rupees and take weeks to manufacture. With medical 3D printing, healthcare professionals can now create perfectly fitted prosthetic hands, legs, and orthotic supports in a fraction of the time and cost.

Aspect |

Traditional Prosthetics |

3D-Printed Prosthetics |

|

Production Time |

4-8 weeks |

3-7 days |

|

Customization |

Limited options |

Fully personalized |

|

Fitting Adjustments |

Multiple visits required |

Precise first-time fit |

|

Weight |

Heavier |

40-60% lighter |

|

Design Iterations |

Difficult and time-consuming |

Quick and easy modifications |

In Bangalore, a young cricket player who lost three fingers in an accident received custom 3D-printed prosthetic fingers that restored his ability to grip a bat. The entire process, from scanning his hand to delivering the finished prosthetic, took just five days. This is the power of 3D printing for healthcare—making the impossible accessible.

Surgical Planning and Practice Models

Surgeons across India are using 3D-printed anatomical models to plan complex surgeries. Before a challenging operation, doctors can now hold a replica of a patient’s organ, tumor, or bone structure in their hands. This allows them to practice the procedure, identify potential complications, and determine the best surgical approach.

At a leading hospital in Mumbai, cardiac surgeons used a 3D-printed model of a child’s heart with a complex congenital defect to plan a life-saving surgery. The model revealed details that weren’t clear on scans, helping the surgical team prepare for complications and reducing the operation time by 40%. The surgery was successful, and the child recovered fully.

Custom Surgical Instruments and Guides

The application of 3D printing in medicine extends to creating patient-specific surgical instruments and cutting guides. These customized tools help surgeons perform procedures with unprecedented precision, especially in orthopedic surgeries like knee and hip replacements.

Consider a patient requiring knee replacement surgery. Using 3D printing, surgeons can create a custom cutting guide based on that patient’s unique knee anatomy. This guide ensures bone cuts are made at exactly the right angles and depths, leading to better implant fit, faster recovery, and improved long-term outcomes.

Dental Applications

Dentistry has embraced 3D printing in hospitals and clinics nationwide. From dental crowns and bridges to clear aligners and surgical guides for dental implants, medical 3D printing has revolutionized dental care delivery.

A dental clinic in Pune reported that switching to 3D-printed dental models and surgical guides reduced their patient appointment times by 50% and improved the accuracy of dental implant placements significantly. Patients experience less discomfort, faster procedures, and better results.

Anatomical Models for Medical Education

Medical students and residents benefit tremendously from 3D-printed anatomical models. Instead of relying solely on textbooks and cadavers, they can study detailed, accurate 3D models of various medical conditions, practice procedures, and develop their skills in a risk-free environment.

A medical college in Delhi incorporated 3D-printed models into its curriculum, allowing students to examine rare pathologies and practice surgical techniques before ever entering an operating room. This hands-on learning approach has dramatically improved student confidence and competence.

Pharmaceutical Research and Drug Testing

Researchers are using medical 3D printing to create tissue models for pharmaceutical testing. These 3D-printed tissue structures mimic human organs, allowing scientists to test new medications more accurately and ethically, reducing the need for animal testing while providing better predictions of how drugs will affect humans.

Common Medical 3D Printing Applications at a Glance

Medical Specialty |

3D Printing Applications |

Key Benefits |

|

Orthopedics |

Joint replacement guides, bone models, custom implants, braces |

Precise alignment, faster surgery, better fit |

|

Cardiology |

Heart valve models, vascular models, and surgical planning |

Improved surgical outcomes, reduced complications |

|

Neurosurgery |

Brain tumor models, skull reconstruction, surgical guides |

Enhanced precision, shorter procedures |

|

Dentistry |

Crowns, bridges, aligners, implant guides, dentures |

Same-day service, perfect fit, lower cost |

|

Maxillofacial Surgery |

Facial reconstruction, jaw models, custom implants |

Natural appearance, functional restoration |

|

Oncology |

Tumor models, surgical planning, radiation guides |

Targeted treatment, margin precision |

|

Pediatrics |

Growth-adaptive prosthetics, congenital defect models |

Cost-effective growth adjustments |

|

Dermatology |

Skin graft templates, wound assessment models |

Better healing outcomes |

Benefits of 3D Printing in Healthcare

Personalization and Precision

Every patient is unique, and 3D printing for healthcare enables truly personalized treatment. Whether it’s a prosthetic limb fitted to exact measurements or a surgical guide designed for a specific patient’s anatomy, this technology delivers precision that mass-produced medical devices simply cannot match.

Cost-Effectiveness

While high-quality 3D printers represent a significant initial investment, the long-term cost savings are substantial. Medical facilities can produce custom devices on demand, eliminating expensive inventory storage, reducing waste, and passing savings on to patients. Medical 3D printing offers significant cost advantages over traditionally manufactured alternatives while maintaining superior quality.

Medical Application |

Time Savings |

Efficiency Improvements |

|

Surgical Planning Models |

5-7 days faster |

50-70% reduction in planning time |

|

Custom Prosthetics |

70% faster delivery |

Multiple iterations possible |

|

Dental Crowns & Bridges |

Same-day possible |

Single-visit treatment |

|

Surgical Guides |

3-5 days faster |

Improved surgical accuracy |

|

Anatomical Training Models |

On-demand production |

Unlimited model availability |

Faster Production and Treatment

Traditional manufacturing of custom medical devices can take weeks or even months. With 3D printing in hospitals, that timeline shrinks to days or even hours. For patients awaiting prosthetics or surgical planning models, this speed can dramatically improve quality of life and treatment outcomes.

Improved Patient Outcomes

Studies consistently show that patient-specific 3D-printed surgical guides and models lead to shorter surgeries, fewer complications, reduced blood loss, and faster recovery times. When surgeons can practice complex procedures on accurate models before surgery, patients benefit from their enhanced preparation and confidence.

Innovation and Accessibility

The application of 3D printing in medicine is democratizing healthcare access across India. Smaller hospitals in tier-2 and tier-3 cities can now offer sophisticated treatment options previously available only at major metropolitan medical centers. This technology is bridging the healthcare gap and bringing world-class medical solutions to underserved communities.

Why Healthcare Professionals Choose Professional 3D Printing Services

While the technology is increasingly accessible, partnering with experienced 3D printing service providers offers distinct advantages:

Advanced Equipment

Professional services use industrial-grade medical 3D printers capable of producing hospital-quality devices with the precision and material properties required for medical applications.

Expertise and Compliance

Understanding medical regulations, biocompatibility requirements, and sterilization protocols requires specialized knowledge. Professional services ensure all printed devices meet necessary safety standards.

Material Quality

Access to certified medical-grade materials that meet FDA and international safety standards is crucial for patient safety.

Fast Turnaround

Dedicated 3D printing facilities can handle urgent medical cases, producing critical devices within tight timelines when patient care depends on it.

Cost Efficiency

Outsourcing to professional services eliminates the need for hospitals to invest in expensive equipment, training, and maintenance while still accessing cutting-edge technology.

The Future of 3D Printing in Healthcare

The application of 3D printing in medicine continues to expand rapidly. Researchers are developing bio printers that can print living tissue and organs, which could revolutionize transplant medicine. Scientists are working on printing customized medications with precise dosages tailored to individual patients.

In India, the 3D printing healthcare market is projected to grow significantly over the next decade as more medical professionals recognize its potential. From metropolitan hospitals to rural health centers, this technology is becoming an essential tool in modern medical practice.

3Ding: Your Trusted Partner for Medical 3D Printing Services

When it comes to 3D printing in healthcare, choosing the right service provider can make the difference between adequate results and exceptional patient outcomes. 3Ding has established itself as India’s premier 3D printing service provider, specifically equipped to meet the demanding requirements of healthcare professionals across the nation.

Why Healthcare Professionals Trust 3Ding

High-Range Industrial 3D Printers

3Ding operates advanced, industrial-grade 3D printing equipment capable of producing medical-grade components with the precision healthcare applications demand.

Medical-Grade Quality and Compliance

Understanding that medical 3D printing requires more than just technical capability, 3Ding maintains strict quality control protocols. Every printed medical device undergoes rigorous inspection to ensure it meets the safety standards required for clinical use. Our team stays current with regulatory requirements and biocompatibility standards, giving healthcare professionals confidence in every delivered product.

Comprehensive Material Selection

3Ding offers an extensive range of biocompatible materials suitable for various medical applications, from medical-grade plastics for anatomical models to sterilizable materials for surgical instruments. Our experts ensure your specific application receives the optimal material choice for safety, durability, and performance.

Fast Turnaround for Critical Cases

We understand that patient care doesn’t wait. 3Ding’s streamlined production process ensures rapid turnaround times, even for complex projects. Whether you need a surgical planning model for an operation scheduled next week or custom prosthetics for a waiting patient, our team prioritizes urgent medical cases.

Expert Consultation and Support

Our technical team works directly with healthcare professionals to understand clinical requirements and translate them into precise 3D-printed solutions. From initial design consultation to final delivery, 3Ding provides hands-on support throughout the entire process, ensuring the finished product perfectly matches your specifications.

All-India Service Network

With service coverage across India, 3Ding makes professional medical 3D printing accessible, whether your facility is in a metropolitan city or a smaller town. Our logistics network ensures safe, timely delivery of medical devices to healthcare facilities nationwide.

Our Medical 3D Printing Services

3Ding specializes in comprehensive medical 3D printing services tailored to healthcare needs:

Surgical Planning Models

Patient-specific anatomical models printed from CT and MRI scans, allowing surgeons to visualize complex cases, plan procedures, and practice techniques before entering the operating room.

Custom Prosthetics and Orthotics

Precisely fitted prosthetic devices and orthotic supports designed from patient scans, offering superior comfort and functionality compared to standard alternatives.

Surgical Instruments and Guides

Patient-specific cutting guides, drill guides, and custom surgical instruments that enhance surgical precision and improve patient outcomes.

Dental Applications

Dental models, surgical guides, crown and bridge patterns, and orthodontic devices are produced with the accuracy dentistry demands.

Medical Education Models

Anatomical models and pathology replicas for medical training, helping students and residents develop skills with realistic, hands-on learning tools.

Implant Prototypes

Pre-surgical implant testing models allow evaluation of fit and function before final implant production or placement.

Real Results from Real Healthcare Partners

Medical facilities partnering with 3Ding report significant improvements in patient care delivery. A multi-specialty hospital in Chennai reduced its pre-surgical planning time by 60% after integrating 3Ding’s surgical models into its workflow. An orthopedic clinic in Jaipur improved prosthetic fitting accuracy and patient satisfaction scores by switching to 3Ding’s custom 3D-printed prosthetics.

These results reflect what’s possible when healthcare expertise meets advanced 3D printing capability, better patient outcomes, improved efficiency, and enhanced reputation for medical excellence.

Take the Next Step in Medical Innovation

3D printing in healthcare represents more than technological advancement—it’s a fundamental shift toward personalized, precise, and accessible medical care. From custom prosthetics that restore quality of life to surgical models that save lives through better planning, medical 3D printing is making a measurable difference in patient outcomes across India.

Healthcare professionals seeking to enhance their treatment capabilities, improve patient satisfaction, and stay at the forefront of medical innovation will find 3D printing an invaluable ally. The technology has moved from experimental to essential, and the question is no longer whether to adopt 3D printing for healthcare, but how quickly facilities can integrate it into their practice.

Partner with 3Ding Today

Whether you’re a surgeon planning a complex procedure, an orthopedic specialist fitting prosthetics, a dentist seeking precision tools, or a medical educator enhancing training programs, 3Ding’s medical 3D printing services offer solutions that transform patient care.

Our team is ready to discuss your specific healthcare applications and demonstrate how our high-range 3D printing technology can benefit your practice and patients. We offer:

-

Free Consultation:

Discuss your medical 3D printing needs with our technical experts -

Project Assessment:

Receive detailed feasibility analysis and cost estimates for your applications -

Sample Production:

Evaluate our quality first-hand with test prints of your designs. -

Ongoing Support:

Access continuous technical support and consultation as your needs evolve

3Ding serves healthcare professionals across India, from metropolitan hospitals to regional medical centers. Our commitment to quality, speed, and medical expertise makes us the trusted choice for the application of 3D printing in medicine nationwide.

Ready to revolutionize your patient care with medical 3D printing? Contact 3Ding today to discover how our advanced 3D printing services can enhance your medical practice, improve patient outcomes, and position your facility at the forefront of healthcare innovation.

The future of healthcare is being printed today, one layer at a time, transforming patient care and saving lives across the nation. Let 3Ding be your partner in this medical revolution. Your patients deserve the precision, personalization, and advanced care that only medical 3D printing can deliver, and 3Ding has the technology, expertise, and commitment to make it happen.

Connect with 3Ding – India’s trusted partner for professional medical 3D printing services. Because when it comes to healthcare, precision isn’t just important—it’s everything.

FAQ related to 3D Printing for Healthcare:

How is 3D printing used in medicine?

3D printing in medicine creates patient-specific devices and models layer by layer from digital designs. Doctors use it to produce surgical planning models from CT/MRI scans, custom prosthetic limbs, surgical guides for precise procedures, dental devices, and anatomical models for medical education across specialities like orthopedics, cardiology, and neurosurgery.

What medical products are 3D printed?

Common 3D-printed medical products include custom prosthetic limbs, surgical planning models of patient organs and bones, patient-specific surgical guides, dental crowns and aligners, anatomical education models, custom implants for reconstruction, and radiation therapy guides. The technology continues expanding into new applications as healthcare professionals discover more uses.

How many hospitals use 3D printing?

Over 100 major hospitals globally have dedicated 3D printing laboratories, with numbers growing rapidly each year. In India, approximately 15-20% of major metropolitan hospitals use 3D printing either through in-house facilities or by partnering with professional service providers like 3Ding, making the technology accessible even to smaller hospitals without expensive equipment.

How do doctors use 3D printing?

Doctors use 3D-printed models from patient scans to study complex cases, practice surgeries, and plan procedures before operations. Surgeons use patient-specific cutting guides for precise joint replacements, dentists create same-day crowns and implant guides, and oncologists plan targeted radiation therapy using printed anatomical models.

What is the future of 3D printing in healthcare?

The future includes bioprinting living tissues and organs to solve transplant shortages, personalized medications tailored to individual genetics, and point-of-care printing for on-demand medical devices. AI integration, improved biocompatible materials, and expanded accessibility to rural areas will make 3D printing as common in hospitals as X-ray machines within the next decade.