India’s 3D printing ecosystem has reached a stage where expectations are no longer limited to basic prototyping. Businesses, manufacturers, design studios, educational institutions, and advanced hobbyists now demand speed, accuracy, repeatability, and flexibility from their machines. In this evolving landscape, traditional single-function 3D printers often fall short.

The Bambu Lab H2D enters the market as a next-generation solution. Rather than functioning as just another desktop printer, it introduces a new category altogether: an all-in-one personal manufacturing hub. By combining high-speed 3D printing, laser engraving and cutting, and digital cutting and plotting into a single platform, the Bambu lab H2D addresses real-world challenges faced by Indian professionals.

This detailed guide explores why the Bambu Lab H2D is widely regarded as one of the best-rated 3D printers, how it compares with conventional machines, and why 3Ding is the right partner to source it from.

Why Indian Professionals Need More Than a Traditional 3D Printer

As manufacturing workflows in India become more advanced, the limitations of standalone 3D printers become increasingly visible. Most growing businesses operate with constrained space, limited capital for multiple machines, and tight delivery timelines. At the same time, customers expect higher quality, tighter tolerances, and faster turnaround times.

Traditionally, achieving a complete workflow required multiple devices and a 3D printer for parts, a laser machine for cutting or engraving, and a digital cutter or plotter for packaging or finishing. While functional, this approach introduces inefficiencies that slow productivity and increase operational complexity.

Common challenges faced by Indian users include:

-

Limited workshop or lab space

-

Higher cost of owning and maintaining multiple machines

-

Time lost switching between software and hardware

-

Inconsistent accuracy when combining multiple processes

-

Growing need for multi-material and hybrid manufacturing

The Bambu Lab H2D addresses these issues by consolidating all major fabrication processes into a single intelligent system, without compromising performance or reliability.

Bambu Lab H2D: A True All-In-One Personal Manufacturing Hub

The defining strength of the Bambu Lab H2D is its ability to handle multiple fabrication methods within a unified workflow. Instead of treating 3D printing, laser processing, and digital cutting as separate tasks, the Bambu Lab H2D integrates them seamlessly.

Core capabilities of the Bambu Lab H2D:

-

High-speed, high-accuracy 3D printing

-

Laser engraving and laser cutting (10W and 40W options)

-

Digital cutting and plotting

-

Pen drawing and marking

This hybrid manufacturing approach reflects how modern products are actually developed, making the Bambu Lab H2D particularly valuable for startups, prototyping labs, and educational institutions in India.

Precision That Reduces Rework and Waste

Accuracy directly impacts the success of functional parts and assemblies. Many conventional desktop printers struggle to deliver consistent dimensional accuracy across large build areas, leading to poor fit and repeated redesigns.

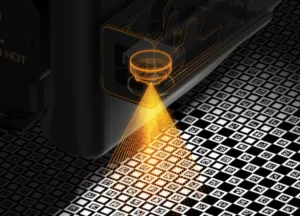

The Bambu Lab H2D addresses this with a motion system that delivers up to 10× higher accuracy than typical desktop machines. Its vision encoder technology enables 50-micron motion accuracy across the entire workspace, reducing the need for manual tolerance adjustments.

Practical benefits of higher motion accuracy:

-

Better fit for mechanical components

-

Fewer test prints and iterations

-

Reduced material waste

-

Higher confidence in functional parts

For Indian manufacturers, this translates directly into lower production costs and faster delivery cycles.

Dual-Nozzle Printing: Reliable Multi-Material Production

Multi-material printing is no longer optional for professional workflows. Whether it’s combining rigid and flexible materials or using soluble supports, users need a system that works reliably.

The Bambu Lab H2D’s dual-nozzle system features fully automatic offset calibration with sub-25-micron accuracy. Unlike older systems that require manual alignment, the Bambulab H2D calibrates itself before every print, ensuring both nozzles behave as one.

What dual-nozzle printing enables:

-

Multi-material parts in a single print

-

Dedicated support materials with minimal waste

-

Faster multi-color printing

-

Cleaner surface finishes

This makes the H2D suitable for both industrial prototyping and creative applications.

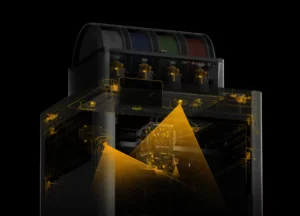

AI-Driven Automation for Consistent Results

Ease of use is often underestimated when evaluating professional equipment. The Bambulab H2D 3D printer integrates AI-powered monitoring and diagnostics to ensure consistent performance across users and projects.

With four computer vision cameras and 36 sensors, the system performs automated pre-flight checks before each job. It identifies potential issues early, minimizing failed prints and downtime.

AI-assisted features include:

-

Automatic hardware and build plate verification

-

Real-time filament flow monitoring

-

Extrusion failure detection

-

Intelligent troubleshooting guidance

For businesses and educational labs, this reduces reliance on highly skilled operators and ensures repeatable results.

Advanced Filament Management with AMS 2 Pro

India’s climate can be challenging for filament storage. Moisture absorption often leads to poor surface quality and weak prints.

The AMS 2 Pro system integrates filament drying, feeding, and sealed storage into one unit. It uses intelligent drying cycles, RFID material recognition, and faster servo-driven feeding to maintain optimal filament condition.

This is particularly beneficial for multi-material and long-duration prints, where consistency is critical.

Laser Engraving and Cutting Built for Real Work

The H2D’s laser module is designed for serious applications, not just occasional use. Available in 10W and 40W variants, it can handle thick plywood, detailed engraving, and complex shapes.

Key laser features:

-

455nm high-power laser

-

Live spatial alignment with up to 0.3mm accuracy

-

Air assist for cleaner cuts

-

Contact-less surface mapping for curved objects

-

Optional rotary attachment for cylindrical engraving

Combined with built-in safety systems, the laser module makes the H2D suitable for workshops, studios, and educational environments.

Digital Cutting and Print-Then-Cut Workflow

The digital cutting function adds significant flexibility to the Bambu Lab H2D. One standout feature is print-then-cut, where printed graphics are automatically aligned and cut using AI vision.

This is ideal for:

-

Packaging prototypes

-

Stickers and labels

-

Educational projects

-

Creative design applications

The result is faster production with minimal manual adjustment.

Built for Speed, Scale, and Engineering Materials

The Bambu Lab H2D is engineered to handle demanding workloads. With a large build volume, a 350°C hot end, and a 65°C actively heated chamber, it supports high-performance materials commonly used in professional applications.

Key performance specifications:

Feature |

Bambu Lab H2D |

|

Build Volume |

Up to 350 × 320 × 325 mm |

|

Maximum Hotend Temperature |

350°C |

|

Chamber Heating |

Active, up to 65°C |

|

Print Speed |

Up to 600 mm/s |

|

Nozzle Type |

Hardened steel, quick-swap |

This combination allows the H2D to move beyond prototyping into functional manufacturing.

Bambu Lab H2D vs Conventional 3D Printers

Capability |

Typical Desktop Printer |

Bambu Lab H2D |

|

3D Printing |

Yes |

Yes |

|

Laser Engraving/Cutting |

No |

Yes |

|

Digital Cutting |

No |

Yes |

|

Multi-Material Printing |

Limited |

Advanced |

|

Motion Accuracy |

Standard |

10× Higher |

|

Filament Drying |

External |

Integrated |

|

AI Monitoring |

Minimal |

Comprehensive |

The comparison highlights why the Bambu Lab H2D delivers significantly higher value for professional users.

Why 3Ding is the Right Place to Buy Bambu Lab H2D?

Choosing the right machine is only part of the decision. 3Ding provides trusted access to genuine Bambu Lab 3D Printers, backed by professional guidance and pan-India delivery.

By working with 3Ding, you will benefit:

-

Expert consultation before purchase

-

Support in choosing the right configuration

-

Reliable logistics across India

-

A partner who understands real-world applications

Conclusion: Is the Bambu Lab H2D Worth It?

For Indian professionals and advanced hobbyists seeking a future-ready manufacturing solution, the Bambu Lab H2D stands out as a clear leader. Its combination of precision, speed, intelligence, and multi-process capability makes it one of the most compelling options in today’s market.

Enquire About Bambu Lab H2D with 3Ding

If you’re exploring the best 3D printers for professionals in India or looking for a detailed Bambu Lab H2D review in India, reach out to 3Ding today. Their team can help you evaluate your requirements and guide you toward the right solution.

FAQs related to Bambu Lab H2D:

1. What kind of laser is in the Bambu Lab H2D?

The Bambu Lab H2D features a high-power 455nm laser available in 10W and 40W options. It supports laser engraving and cutting on various materials with precise spatial alignment up to 0.3mm, making it ideal for professional and creative applications in India.

2. How good is the Bambu Lab H2D?

The Bambu Lab H2D is one of the best 3D printers for professionals and hobbyists in India. It combines high-speed 3D printing, multi-material capabilities, laser engraving, and digital cutting in a single all-in-one platform, delivering reliable, accurate, and versatile results.

3. How accurate is the Bambu Lab H2D?

The Bambu Lab H2D achieves a motion accuracy of up to 50 microns using its advanced vision encoder system and AI-assisted calibration. This ensures precise prints, perfect fits for mechanical parts, and consistent quality across large and complex projects.

4. Does Bambu Lab H2D print faster?

Yes, the Bambu Lab H2D supports high-speed printing at speeds of up to 600mm/s. Its advanced hot end, servo-driven filament system, and dual-nozzle setup allow fast multi-material and multi-color printing without compromising surface quality or accuracy.

5. Can Bambu Lab H2D be upgraded?

The Bambu Lab H2D is highly upgradeable. You can add optional features like the rotary attachment for cylindrical engraving, the AMS 2 Pro for advanced filament management, and the vision encoder for even higher precision, making it a future-ready solution for Indian professionals.